Liquid-cooled fully sealed high-efficiency radiating electronic cabinet

A fully enclosed, chassis technology, applied in refrigerators, cooling/ventilation/heating transformation, compressors, etc., can solve the problems of low power, bulky, bulky, etc., and achieve low cost, high heat exchange efficiency, and small volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

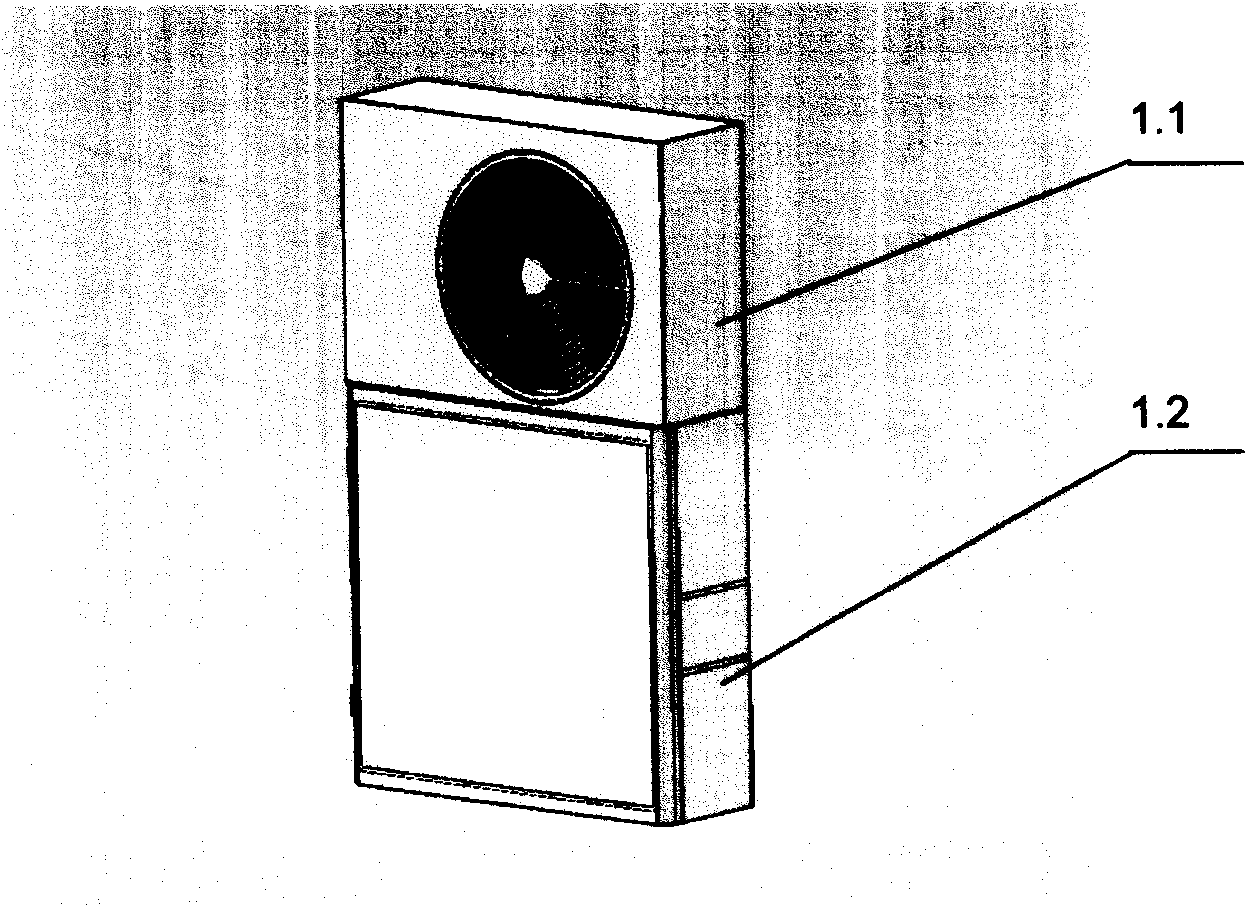

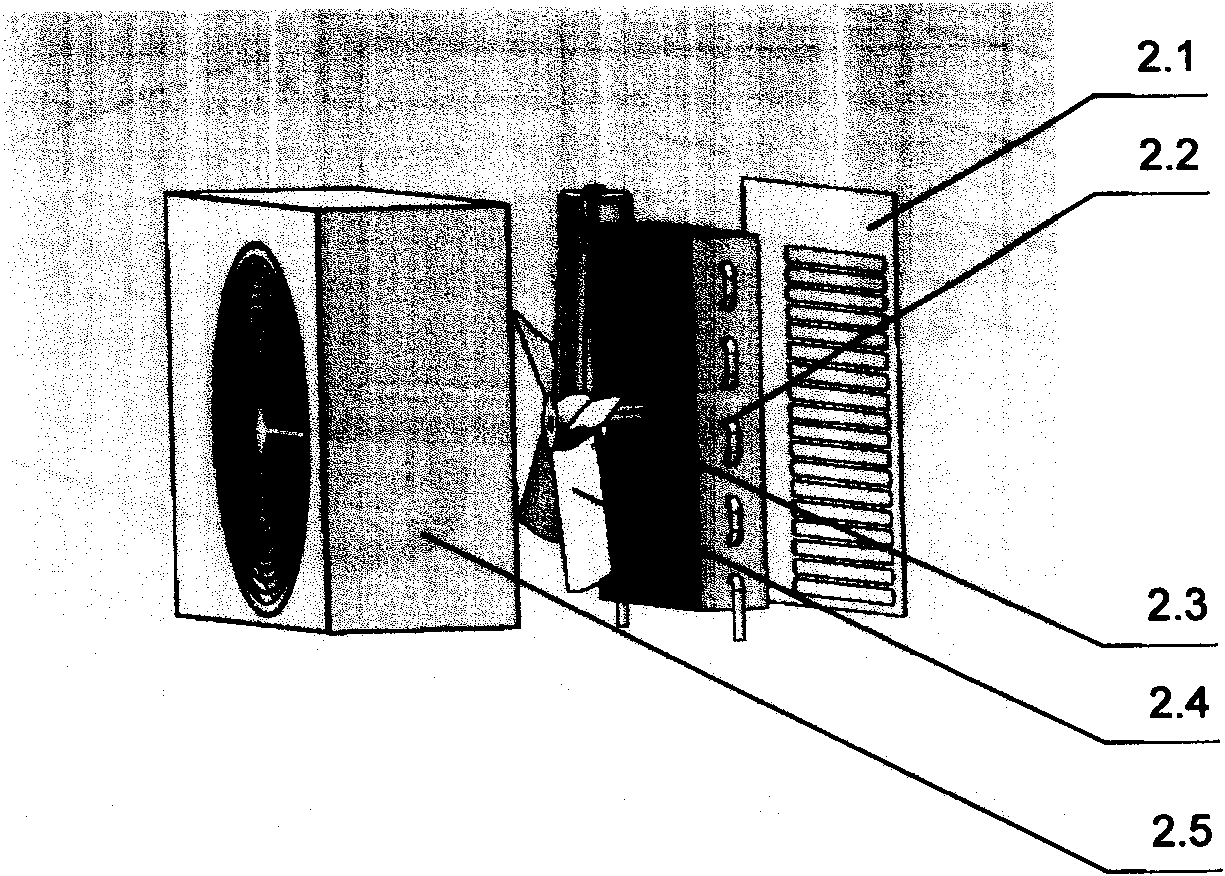

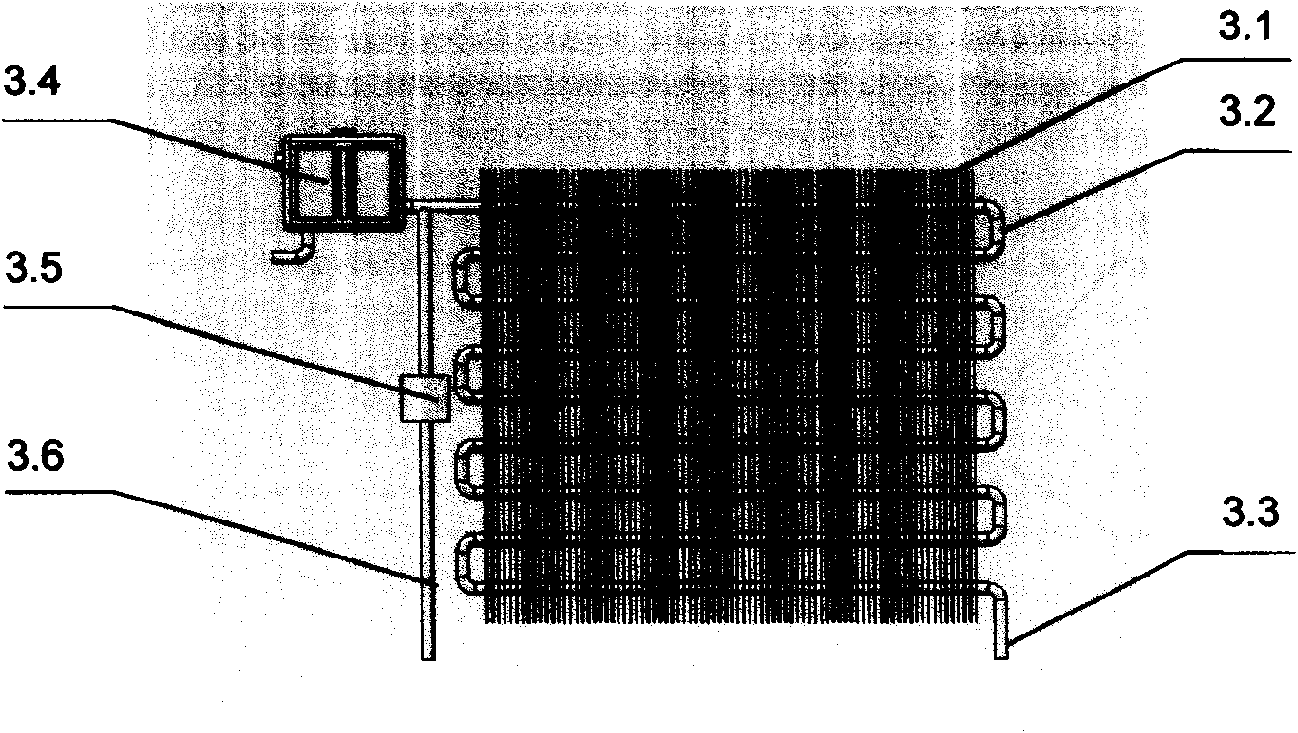

[0028] The invention provides a heat dissipation method and a heat dissipation device for a fully enclosed electronic chassis that needs to be waterproof, moisture-proof, dustproof and electromagnetic shielding. The method and device adopt a mutually independent design method for the fully enclosed electronic chassis host and the external radiator chassis , In order to realize the full enclosure of the electronic chassis host; the heating electronic components are fixed on the inner radiator inside the host, the inner radiator is made of high thermal conductivity metal materials such as aluminum, copper, etc., and the heat generated is inside the inner radiator The circulating liquid cooling is exported to the outer radiator for cooling, in order to achieve the purpose of efficient heat dissipation.

[0029] The liquid-solid phase point of the cooling liquid in the circulating liquid cooling device is not lower than minus 20°C, and the boiling point is not lower than 90°C. So as t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com