Heat radiation method for high-power electronic part and heat radiation device using this method

A technology for electronic devices and heat dissipation methods, applied in the direction of cooling/ventilation/heating transformation, etc., can solve the problems of many consumables for heat dissipation plates, increase wind resistance, and high processing costs, and achieve the effects of high heat exchange efficiency, temperature control, and small size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

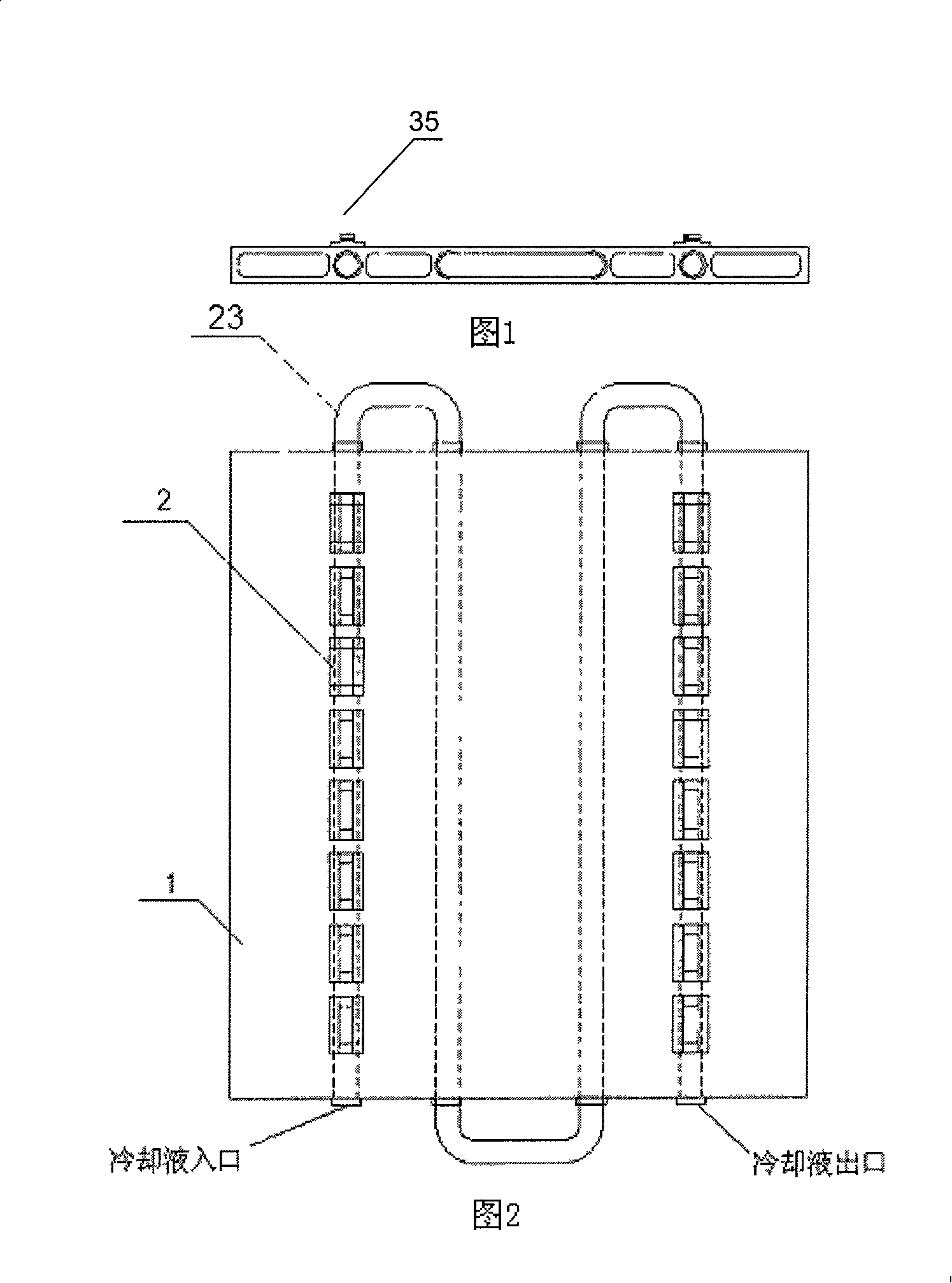

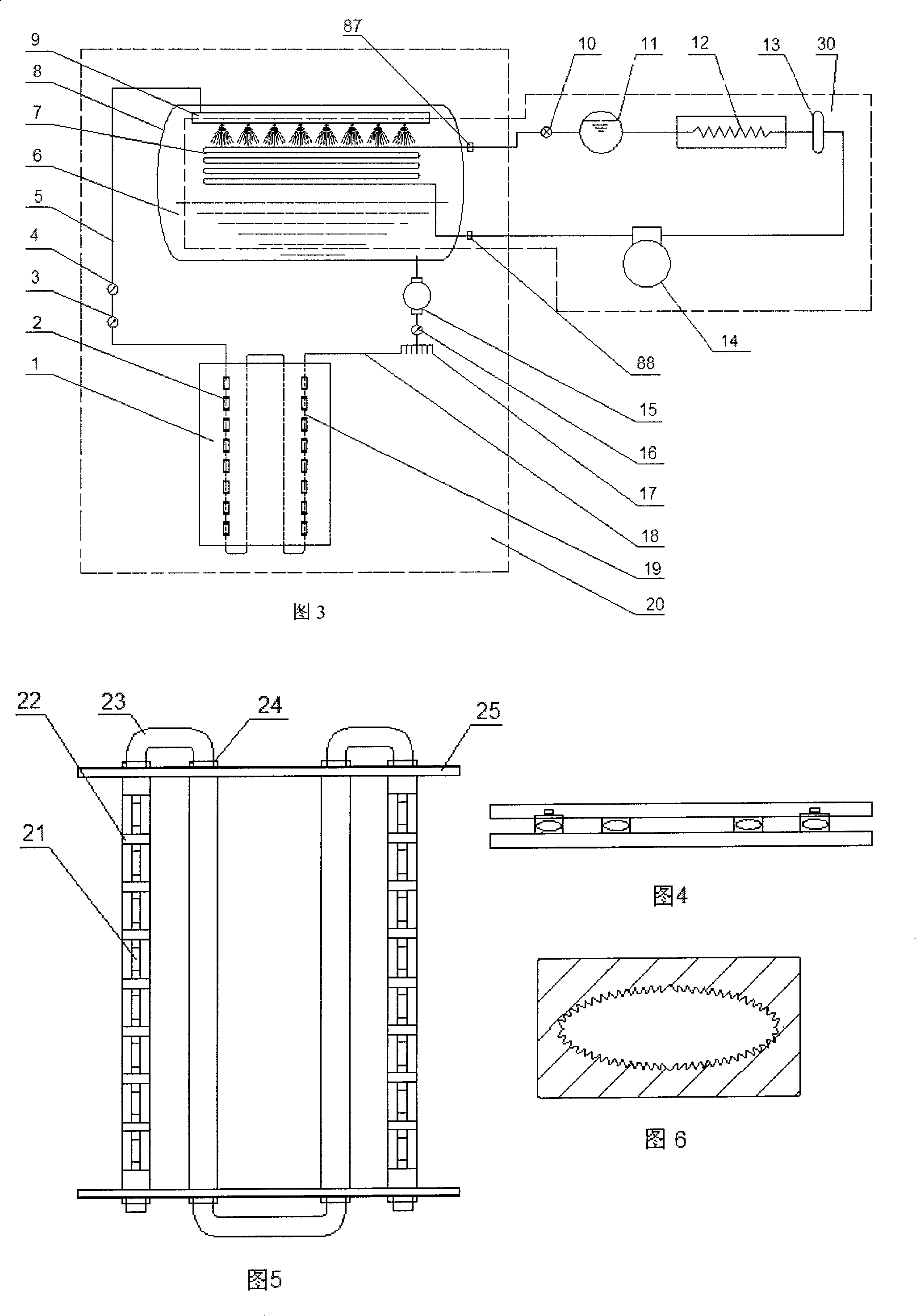

[0040]A method for heat dissipation of high-power electronic devices provided by the present invention, the method adopts a two-stage circulating cooling device, wherein: the first-stage circulating cooling device is a circulating liquid cooling device, and the circulating liquid in the circulating liquid cooling device is equipped with The radiator of the heating electronic component performs heat exchange to cool the heating element on the radiator; the second-stage circulating cooling device is a heat pump refrigeration device, and the heat pump refrigeration device cools the circulating fluid. The liquid-solid phase point of the cooling liquid in the circulating liquid cooling device is not lower than minus 20°C, and the boiling point is not lower than 90°C. In this way, the working temperature range of the cooling liquid can be controlled, and the component failure caused by the temperature being too low or too high can be avoided. Specifically, use 30% to 60% ethylene gl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com