Patents

Literature

34results about How to "Meet the requirements of high temperature use" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

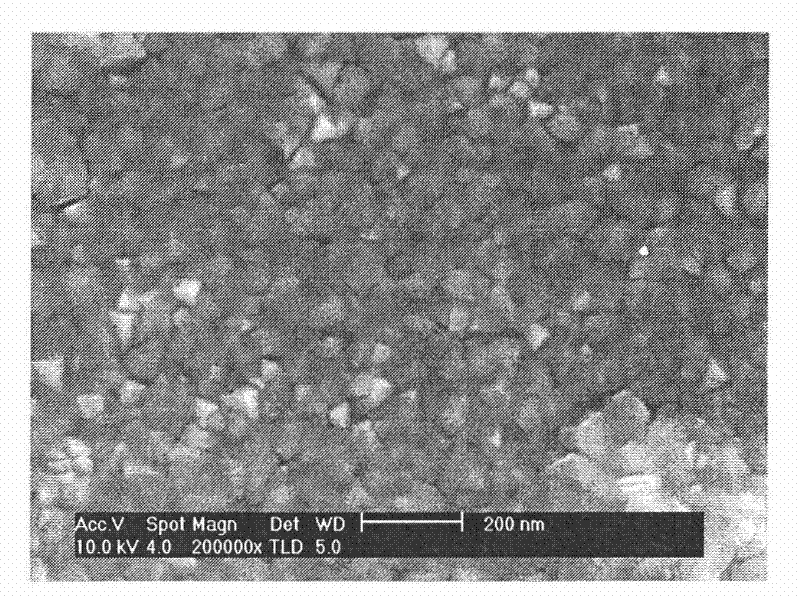

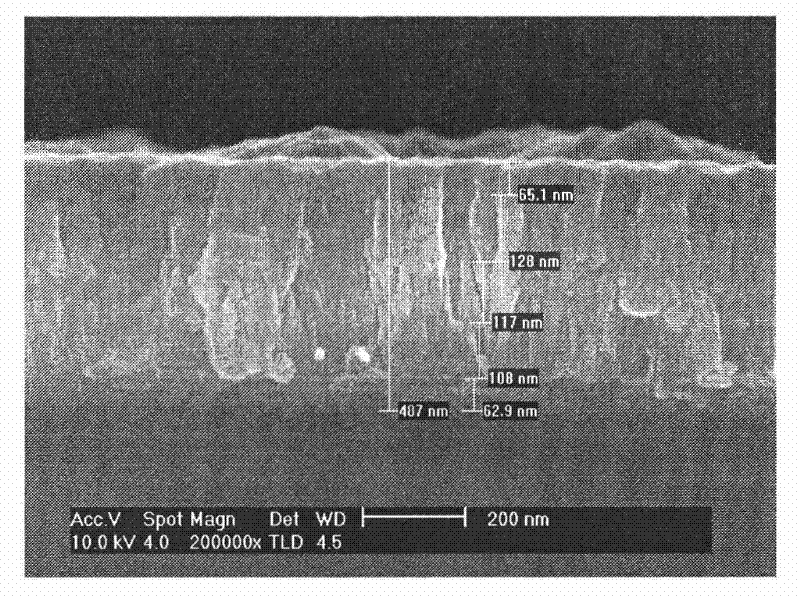

Solar spectrum selective absorbing coating and preparation method thereof

ActiveCN102122006AHigh absorption rate αLow high temperature oxidation resistanceVacuum evaporation coatingSputtering coatingHigh absorptionLow emissivity

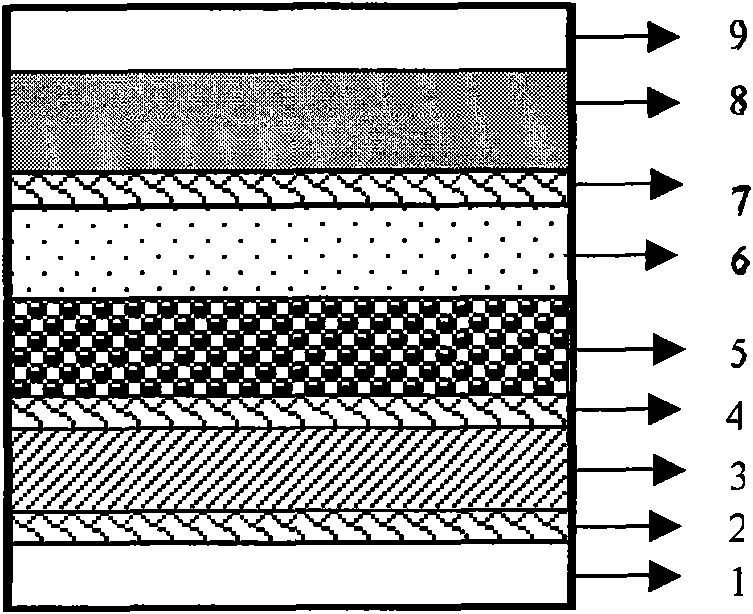

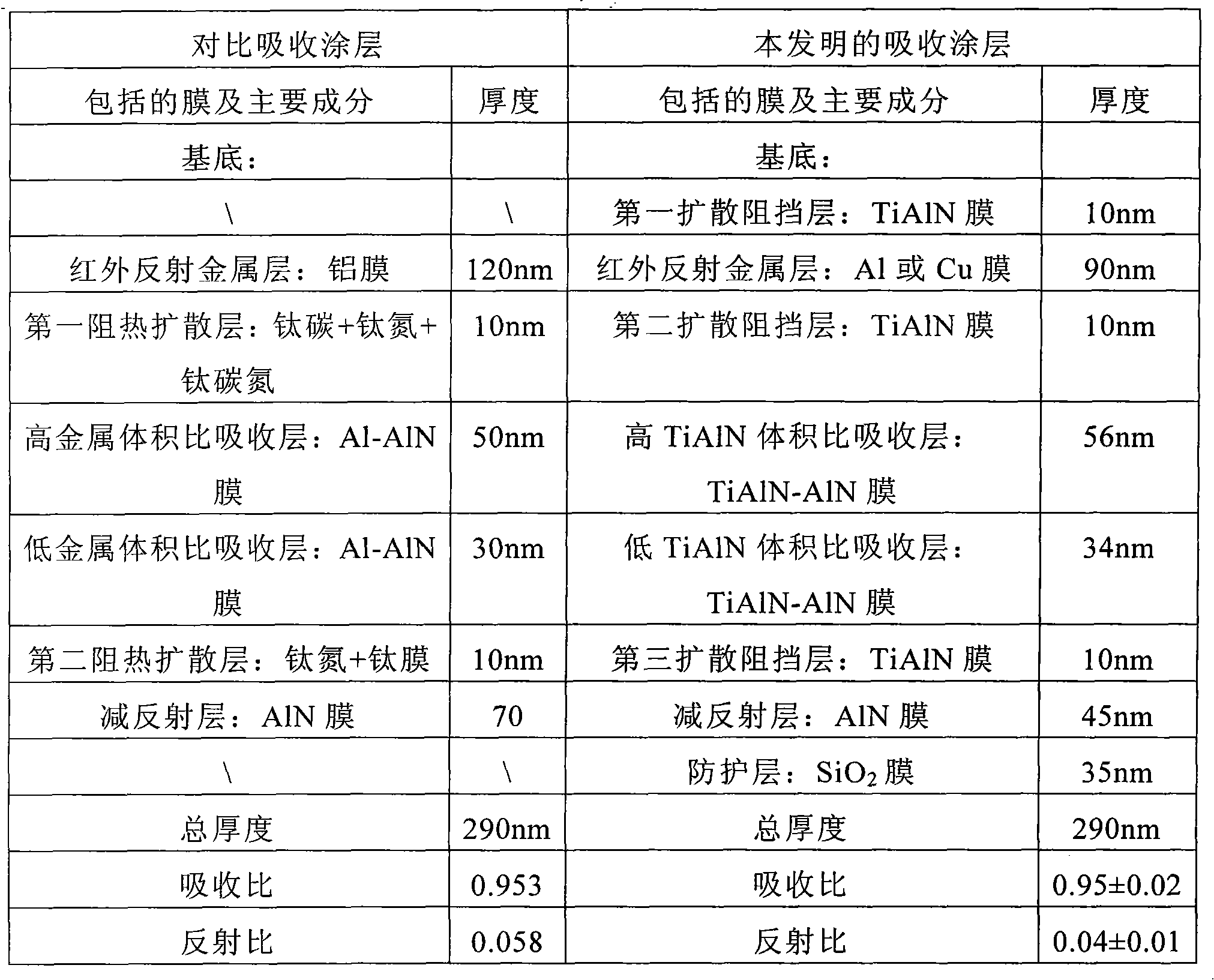

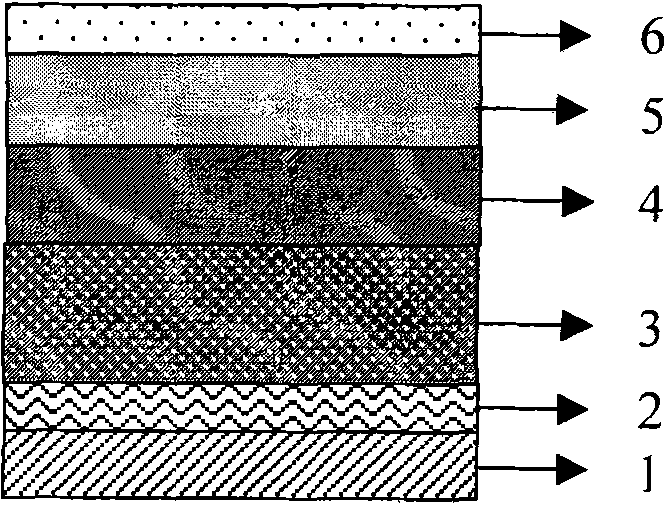

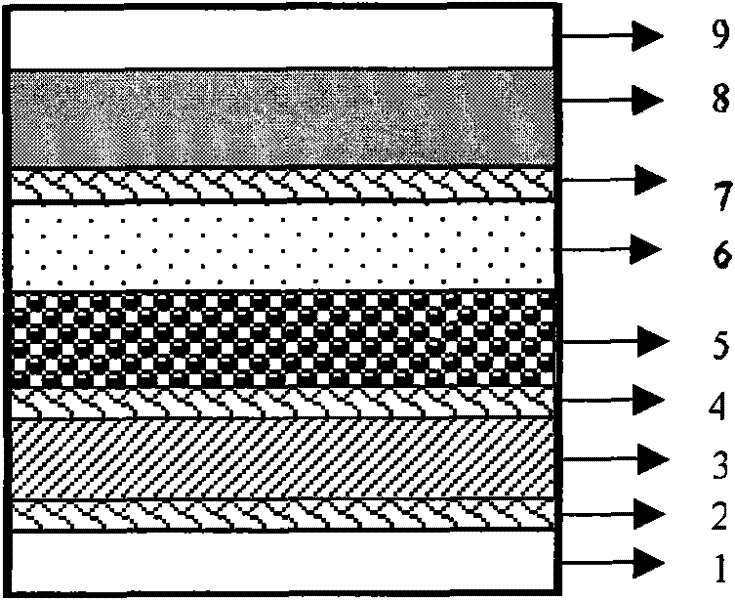

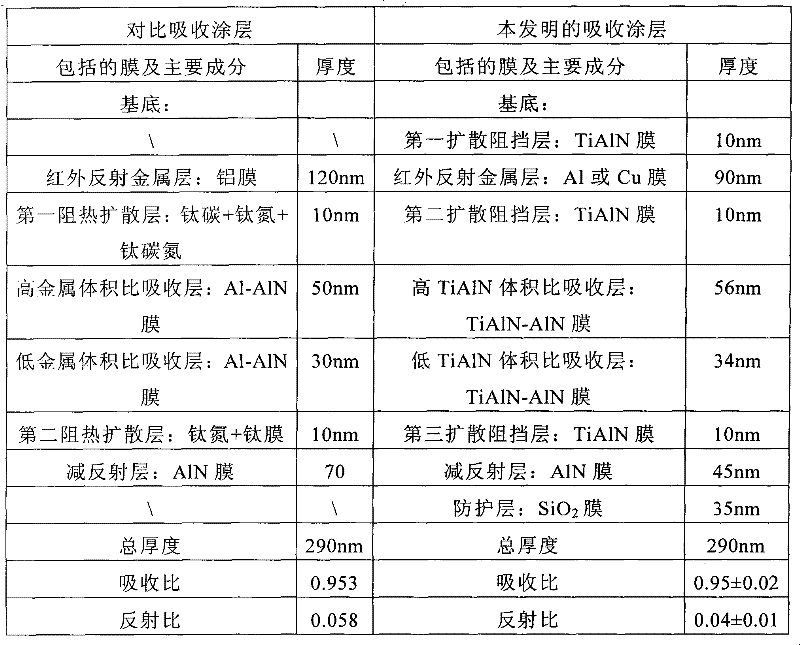

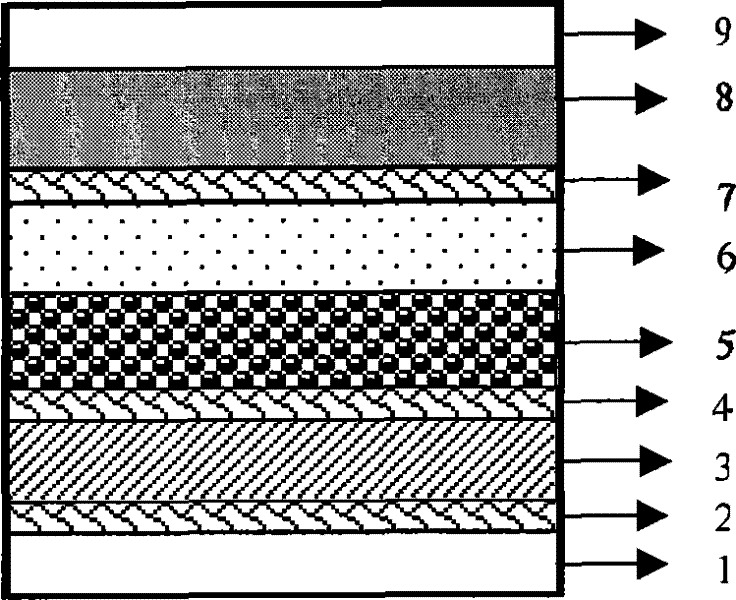

The invention provides a solar spectrum selective absorbing coating and a preparation method thereof, wherein the preparation method comprises the following steps of: (1): selecting copper or stainless steel as substrate material; (2): selecting high-temperature oxidation resisting TiAlN as a diffusion impervious layer, using pure metal Cu or Al as a high infrared reflective layer, wherein an absorbing layer consists of two conductive particle-ceramic (AlN) composite layers with different volume percentages of metal nitride conductive particle (TiAlN), using AlN as an antireflection layer, and using SiO2 as a protective layer; (3): controlling components and contents of different film materials by controlling the gas flow and the sputtering power and the like; (4): before placing the substrate material into a vacuum chamber, carrying ultrasound treatment on the substrate material for 10-30 min, drying, after placing the substrate material into the vacuum chamber, roasting for 10-30 min at 100-120 DEG C, before sputtering, bombarding the surface by argon ions; and (5): obtaining a coating with a multi-layer structure, which has high absorption rate Alpha (0.95 + / - 0.02) in the solar spectral region (0.3-2.5 micrometers), and which has quite low emissivity Epsilon (0.04 + / - 0.01) in an infrared region (2.5-50 micrometers).

Owner:GRIMAT ENG INST CO LTD

Bonded polyolefine resin composition

ActiveCN101074305AReduce degradation reactionIncrease reaction rateLinear low-density polyethylenePolyolefin

An adhesive poly-olefin resin composite consists of grafted polypropylene 0.1-40 wt% ( MFR 1-40 wt%), polypropylene 20-48 wt% ( MFR 0.3-40 wt%), linear low-density polythene 20-40 wt% ( MFR 0.8-10 wt%), high-density polypropylene 10-30 wt% ( MFR 2-5 wt%), multi-polymer of ethylene and octane 1-20 wt% in proportion of 1:1 ( MFR 0.5-30 wt%) and polystyrene 1-10 wt%. Grafted polypropylene is unsaturated carboxylic acid, anhydride or carboxylic ester as the first grafting monomer, styrene is the second grafting monomer, the grafting rate of unsaturated carboxylic acid, anhydride or carboxylic ester of polypropylene is 1-10 wt%. It has excellent binding performance with steel, iron and aluminum, peeling strength is >=80 N / 10 mm, and softening point is >=120 degree(GB 1613-90). It can be used for chemical container and pipeline.

Owner:PETROCHINA CO LTD

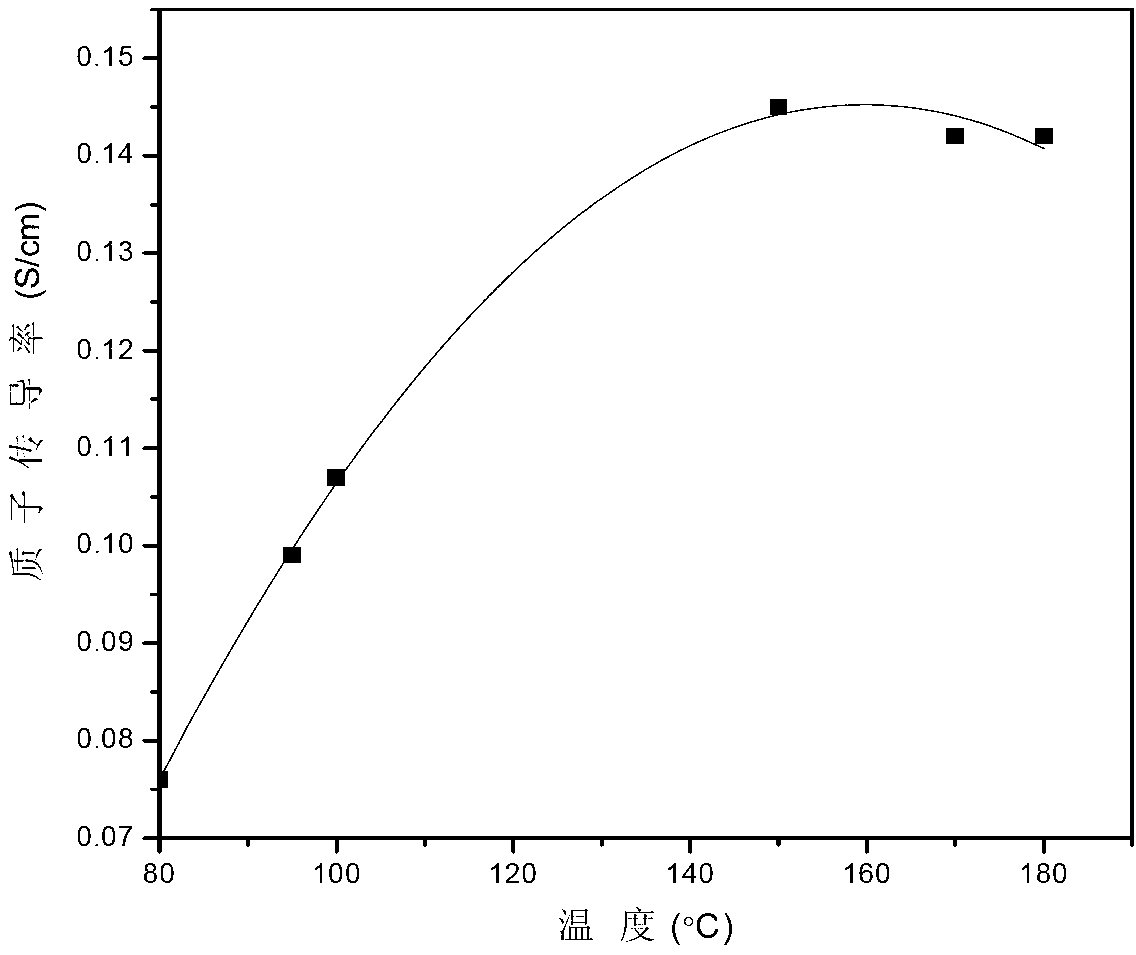

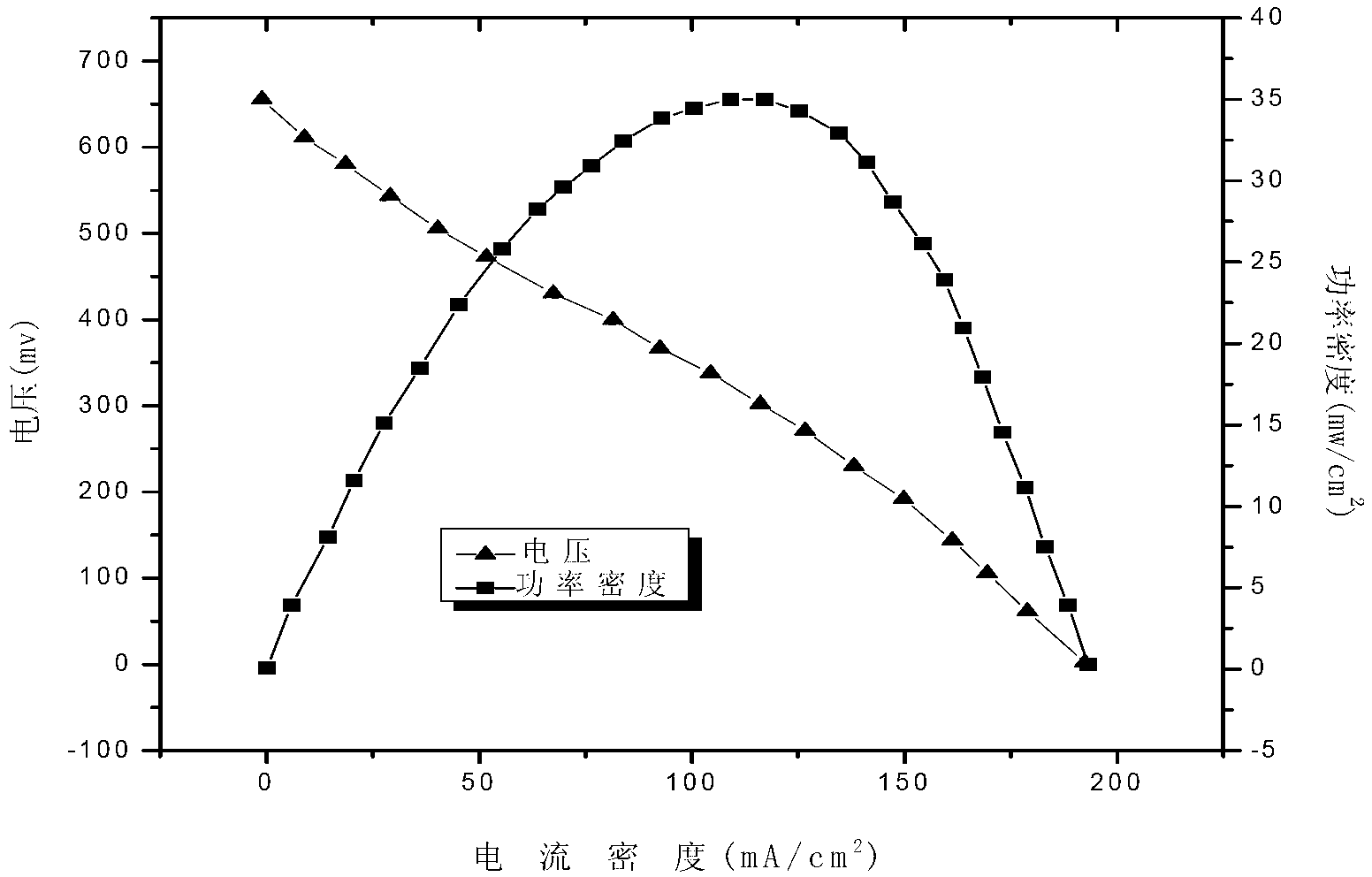

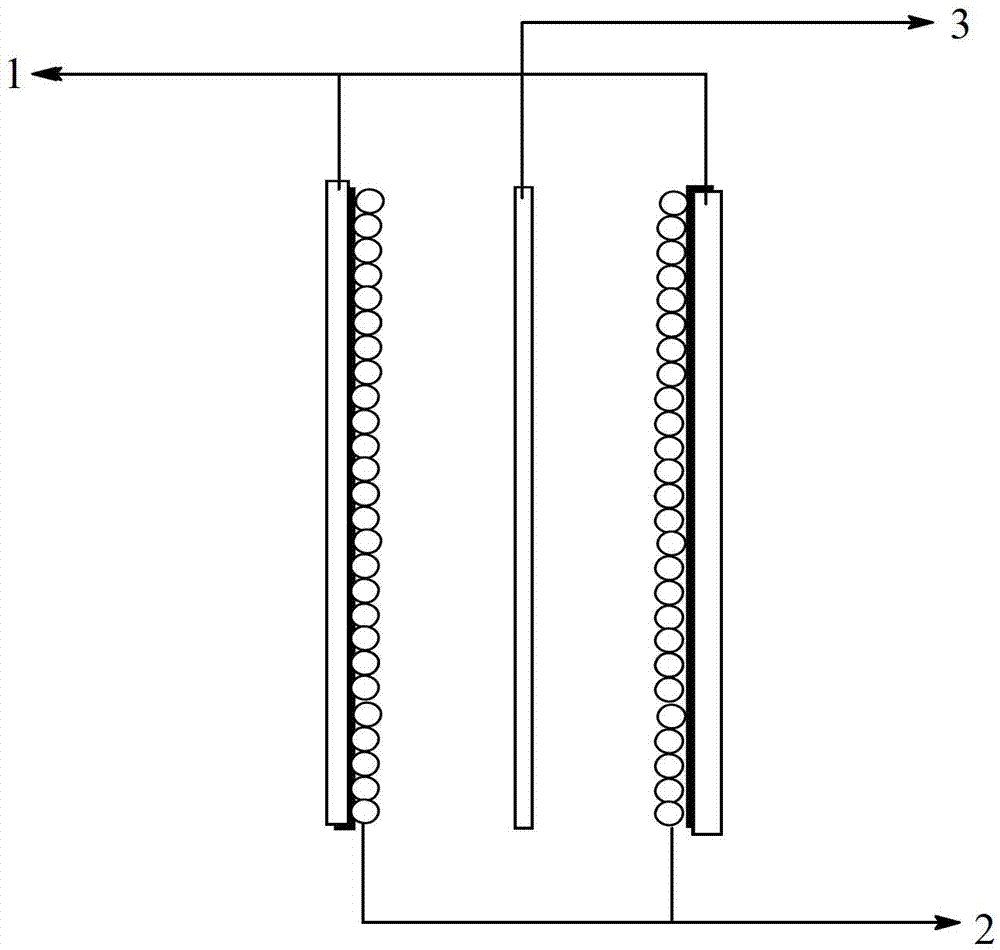

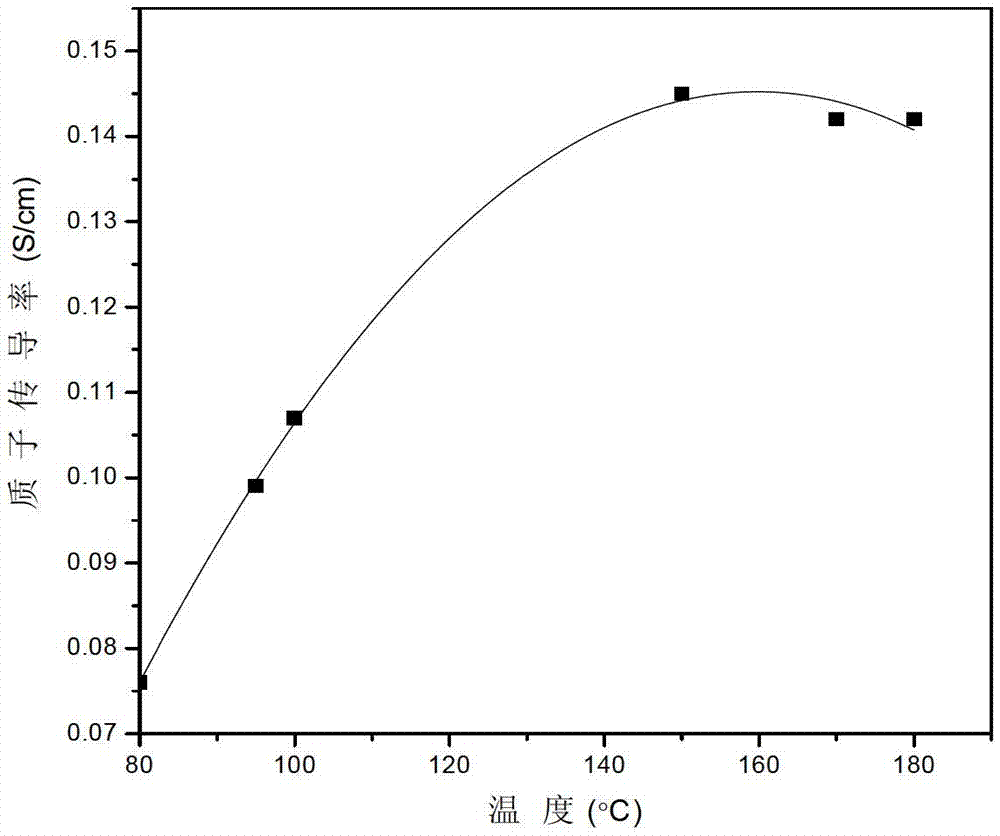

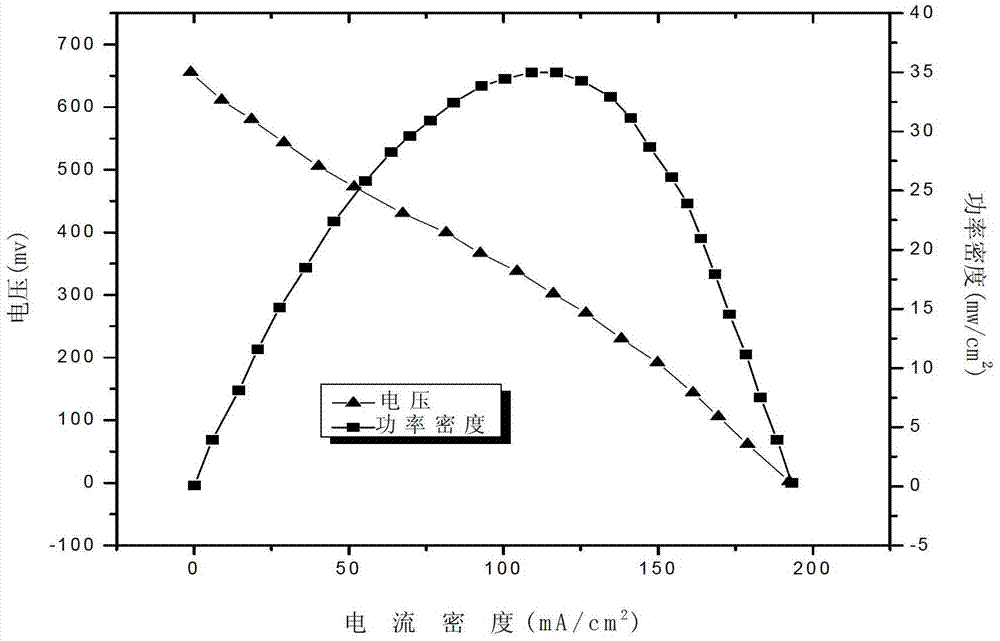

Proton exchange membrane and preparation method thereof

ActiveCN103236557AOmit separabilityOmit solubilityFinal product manufactureSolid electrolyte fuel cellsProtonPhosphoric acid

The invention relates to a proton exchange membrane and preparation method thereof, and the proton exchange membrane is a Poly-p-phenylene ben-zobisthiazole and polyphosphoric acid blend membrane (PBO / PPA), and the method for preparing the Poly-p-phenylene ben-zobisthiazole and polyphosphoric acid blend membrane (PBO / PPA) as a proton exchange membrane comprises: (1) polymerizing and obtaining a PBO / PPA slurry; (2) preparing the PBO / PPA slurry into a PBO / PPA proton exchange membrane; (3) controlling the thickness of the membrane by controlling the concentration of the polymer solution and the compacting temperature and pressure; (4) carrying out a proton conductivity test directly after the membrane is taken out and the membrane is used as a proton exchange membrane is assembled in the H2 / O2 fuel monocell for investigating power generation performance. The invention selects an appropriate film forming technology according to the characteristic of the PBO rigid molecular chain, and has the advantages of simple preparation technology and easy control, and the obtained proton exchange membrane has a higher proton conductivity under high temperature with excellent power generation property.

Owner:DONGHUA UNIV

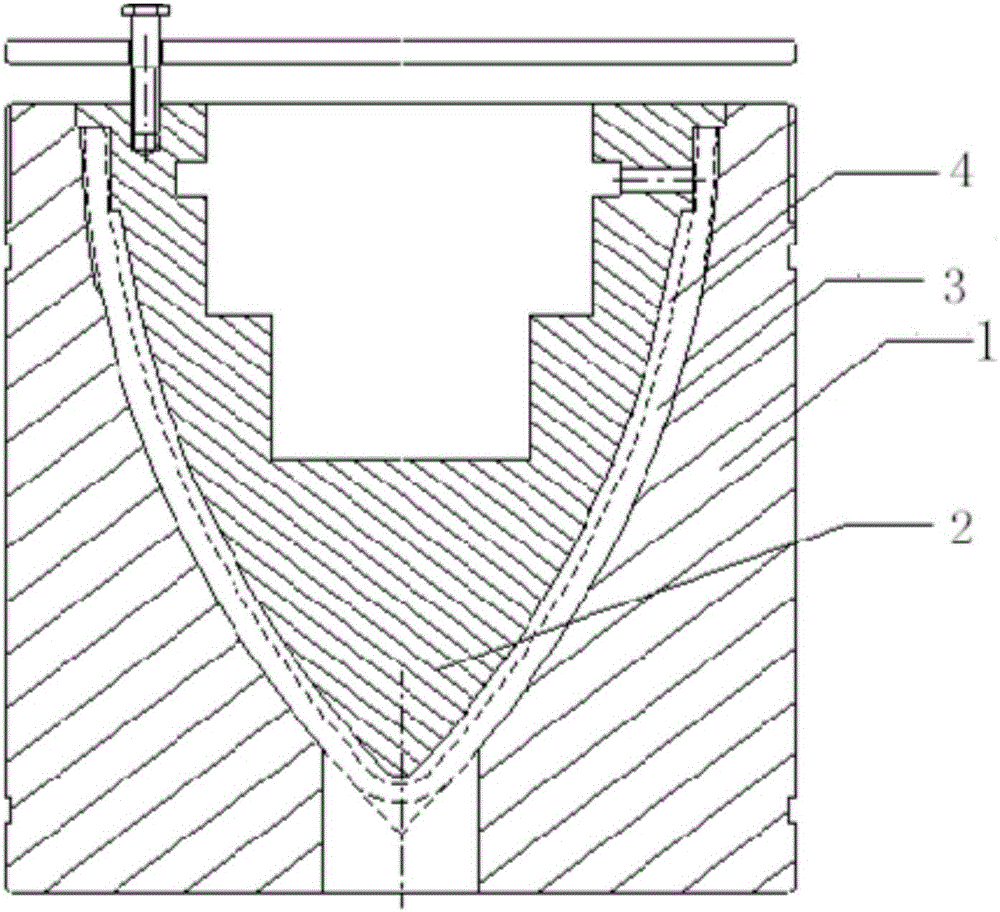

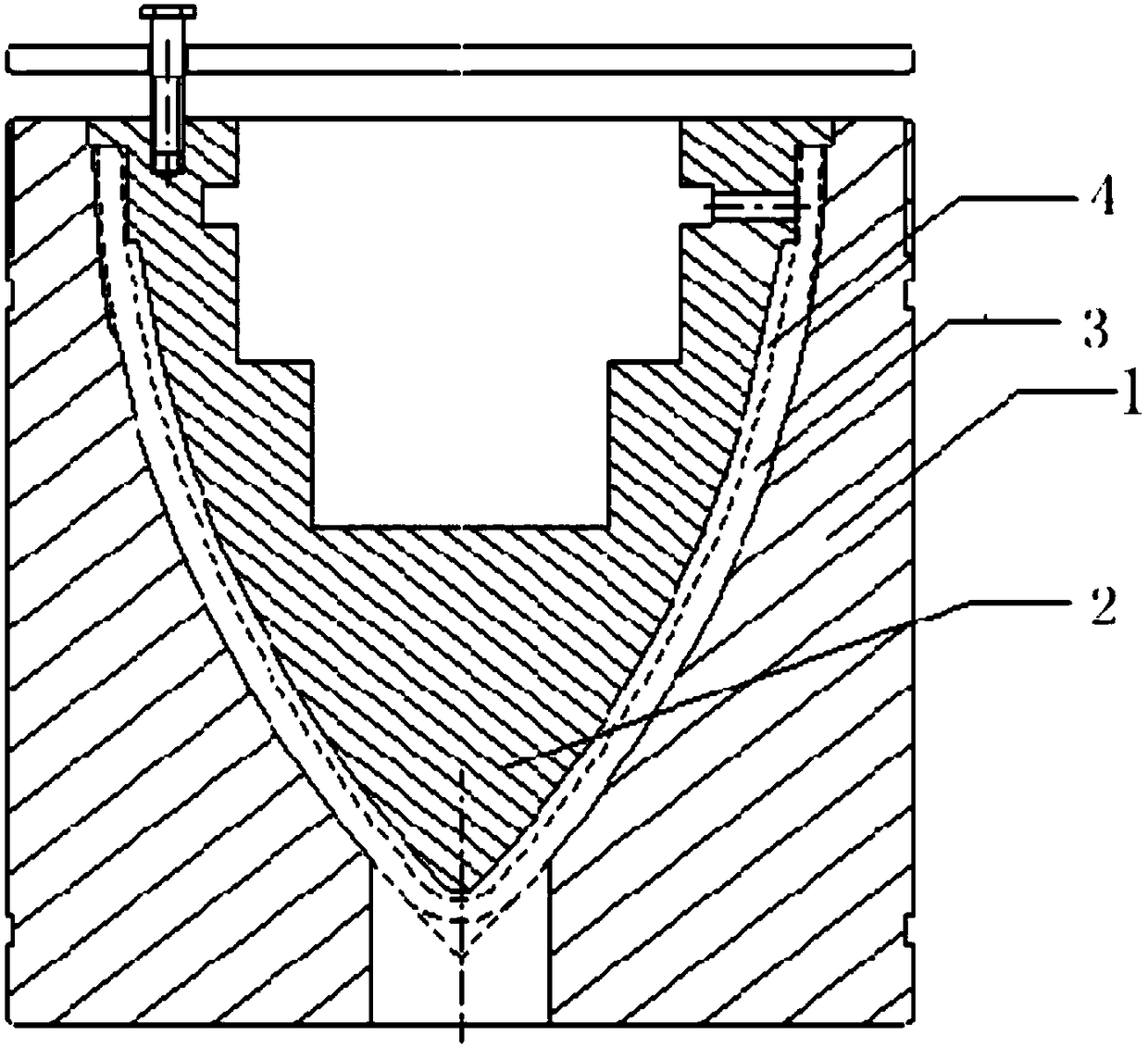

Method for preparing double-layer wave-permeable heat proofing and insulating composite structural part

The invention discloses a method for preparing a double-layer wave-permeable heat proofing and insulating composite structural part. The structural part comprises an inner heat insulation material and an outer heat-proof +material. The method includes steps of preparation of the outer heat-proof material, preparation of silicon oxide hollow microspheres, preparation of chopped fiber reinforced silicon oxide hollow microsphere slurry, casting of the chopped fiber reinforced silicon oxide hollow microsphere slurry and thermal treatment of a structural part blank material. Quartz fiber reinforced quartz composite ceramic serves as the outer heat-proof material, chopped fiber reinforced silicon oxide hollow microsphere ceramic serves as the inner heat insulation material, compact combination of the inner and outer materials is realized by means of slurry casting and high-temperature sintering moulding, and integration of advantageous performances of high temperature resistance, heat proofing, heat insulation, wave permeability and the like is realized.

Owner:湖北三江航天江北机械工程有限公司

High temperature FeNiCo magnetostriction alloy as well as preparation method thereof

ActiveCN103556005AImprove magnetic propertiesMeet the requirements of high temperature useChemical compositionCurie temperature

The invention discloses a high temperature FeNiCo magnetostriction alloy as well as a preparation method thereof. The alloy comprises the following chemical components in percent by weight: 30.0-55.0% of Ni, 1.0-22.0% of Co, 1.0-3.5% of Cr, 1.0-3.5% of Mo, 1.0-3.0% of Ti, 0-2.0% of Al, 0-0.006% of B and the balance of Fe. The high temperature magnetostriction alloy disclosed by the invention has high Curie temperature, good magnetic performance and great saturated magnetostriction coefficient in a relatively wide temperature range, and can satisfy the using demands of high precision instruments and meters at high temperatures.

Owner:CHONGQING MATERIALS RES INST

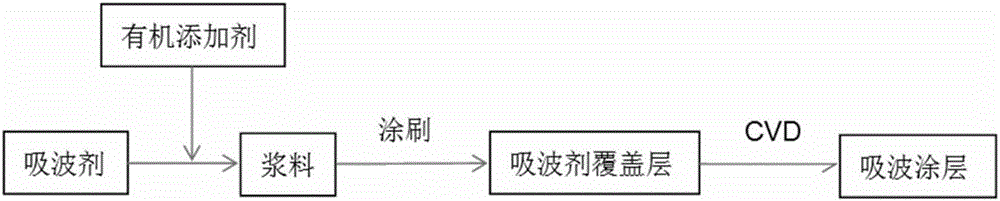

Low-temperature preparation method of ceramic coating absorbing waves in frequency band of 8-18 GHz

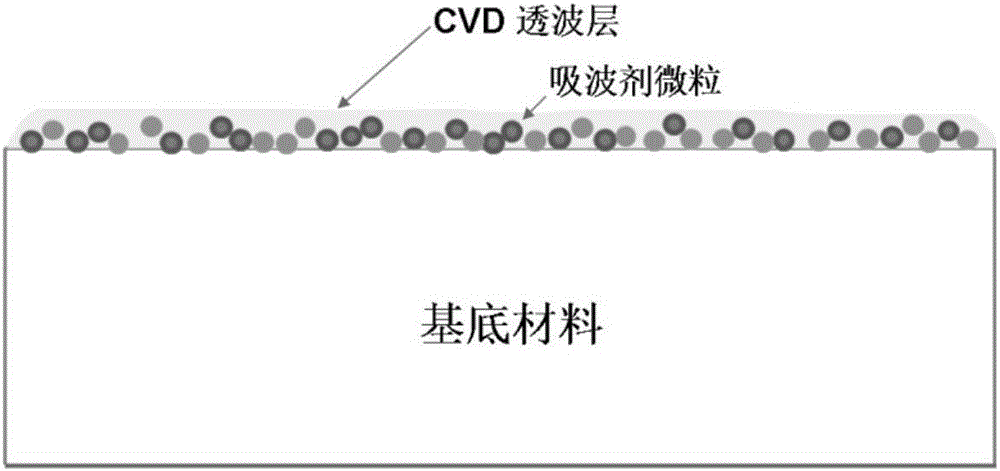

InactiveCN106588124AGood high temperature resistanceStrong designabilityLiquid surface applicatorsRadiation-absorbing paintsFrequency bandCeramic coating

The invention relates to a low-temperature preparation method of a ceramic coating absorbing waves in the frequency band of 8-18 GHz. Firstly, the surface of a substrate material is uniformly brushed with slurry containing a wave absorbing agent by adopting a brushing method, and a wave-transmitting layer is prepared on the surface of the wave absorbing agent through a chemical vapor deposition technology after standing and drying in the shade. The wave absorbing coating and the substrate material are well bonded, and the wave absorbing performance of the material can be remarkably improved. The method has very strong designability, for example, a coating structure and components can be optimized by adjusting the type of wave absorbing agents, the type of wave-transmitting layers, deposition time and other parameters, and accordingly the substrate material can obtain good wave absorbing performance.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Lanthanum-oxide-modified rubber cable material

InactiveCN105985552AImprove reinforcement effectGood chemical stabilityRubber insulatorsVulcanizationCarbon nanotube

The invention discloses a lanthanum-oxide-modified rubber cable material which is prepared from the following raw materials in parts by weight: 5-6 parts of tantalum carbide, 0.6-0.8 part of lanthanum oxide, 62-68 parts of hydrogenated nitrile-butadiene rubber, 10-13 parts of carbon nanotube, 7-9 parts of nano kaolin, 55-60 parts of chloroprene rubber, 1-1.5 parts of montanin wax, 2-2.4 parts of calcium stearate, 2-3 parts of epoxy soybean oil, 2-3 parts of vulcanization accelerator TMTD, 55-70 parts of natural rubber, 2-3 parts of decabromodiphenyl oxide, 30-40 parts of hollow glass microsphere, 1-1.3 parts of silane coupling agent kh550, 12-16 parts of epoxy resin E44, 0.06-0.1 part of diethylenetriamine, 0.1-0.2 part of accelerator DA, 2.6-3 parts of silane coupling agent kh570 and a right amount of distilled water. The cable material has favorable flame retardancy, satisfies the requirements for application at high temperature, and has the advantages of favorable aging resistance, favorable oxidation resistance and longer service life.

Owner:JING FENG GRP

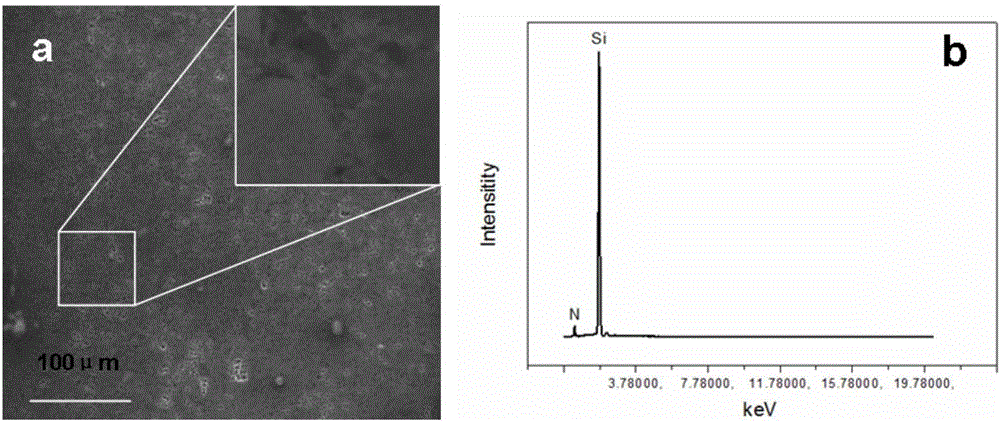

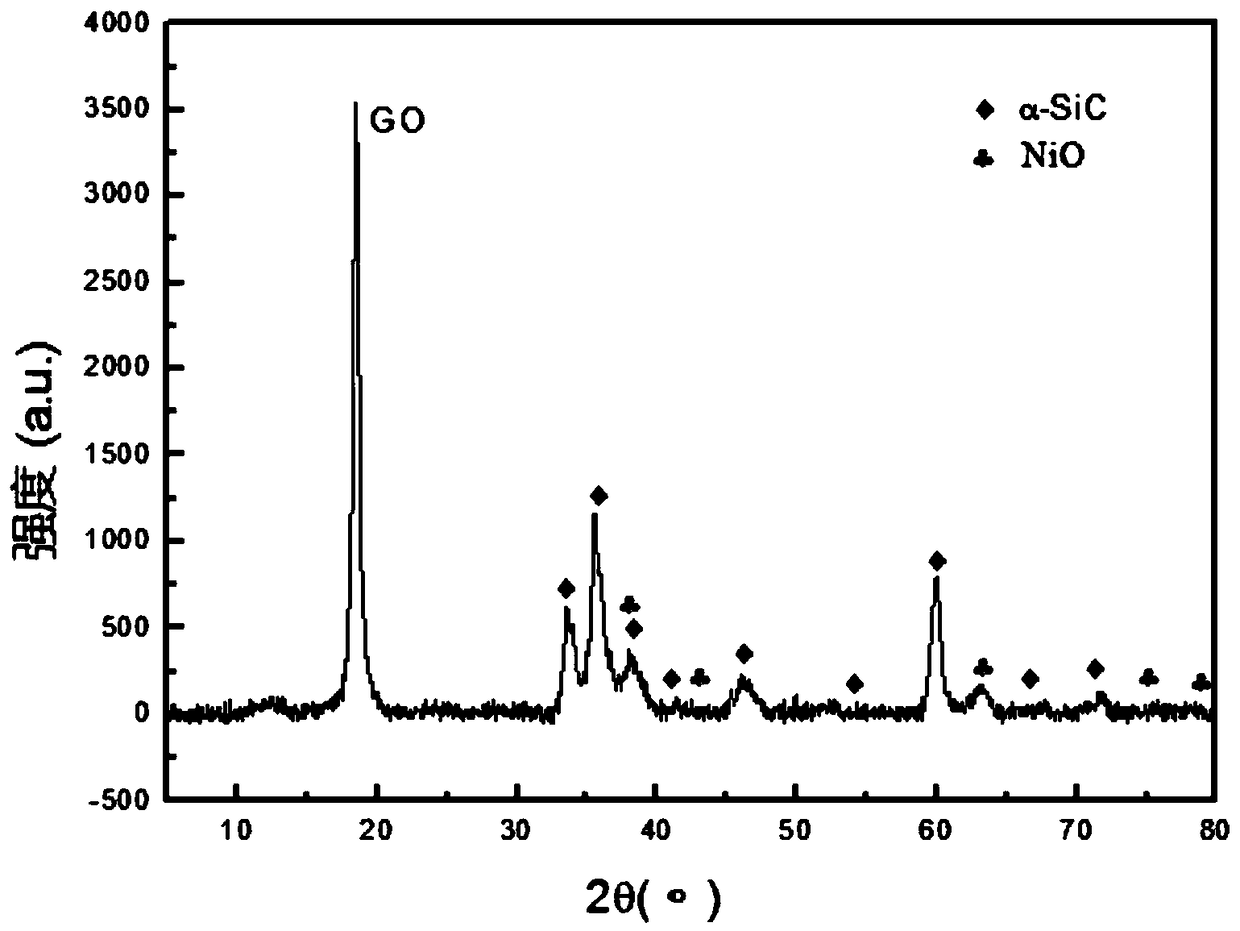

SiC-ferrite/carbon material high-temperature wave absorption composite material and preparation method thereof

The invention provides a SiC-ferrite / carbon material high-temperature wave absorption composite material and a preparation method thereof, and relates to a wave absorption composite material. The material aims at solving the technical problems of processing complexity, high cost and poor wave absorption effect of the existing wave absorption material. The wave absorption composite material provided by the invention is prepared from ferrite, silicon carbide and carbon materials. The preparation method comprises the following steps of 1, performing silicon carbide surface pretreatment, 2, uniformly mixing hydrophilic silicon carbide, ferrite preparation soluble salts, fluorides, a precipitant, a carbon material, a silane coupling agent, alcohol and water; performing hydro-thermal synthesis to obtain precursors; and then, roasting the precursors to obtain the wave absorption composite material. The 90-percent absorption can be reached at the X waveband being 8 to 12GHz; the reflection loss is lower than -10dB; and the maximum reflection loss reaches -28dB. The material can be used in the fields of monitoring of ground nuclear reactor systems, crude oil exploration, environment monitoring, aviation, spaceflight, radar, communication systems, high-power electronic converters and automobile motors.

Owner:HARBIN INST OF TECH

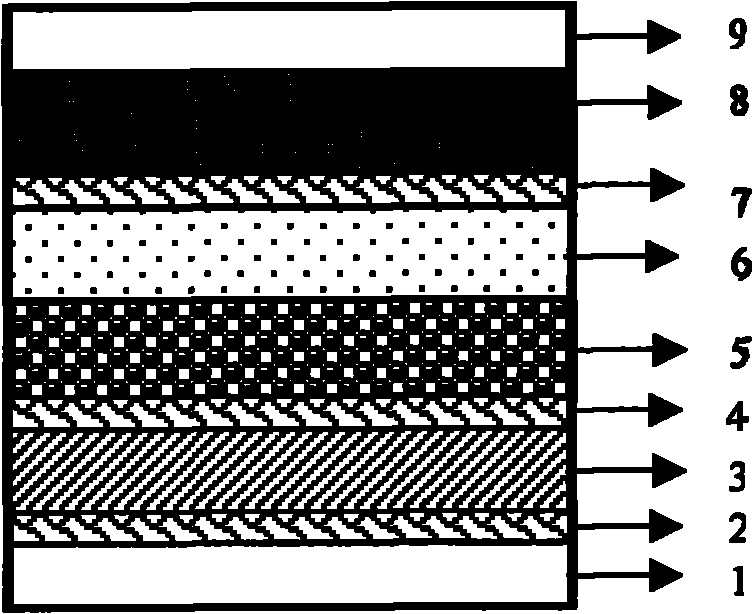

A non-vacuum solar spectrum selective absorption film layer and its preparation method

ActiveCN101666557BSolve Oxidation ProblemsChange colorSolar heat devicesVacuum evaporation coatingHigh absorptionArgon atmosphere

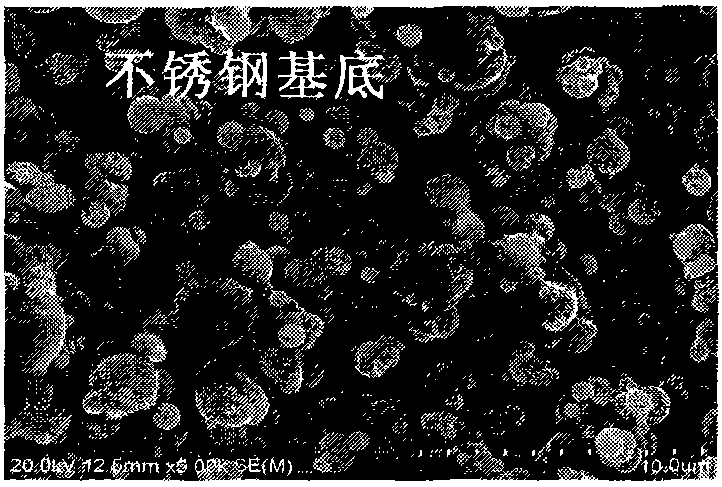

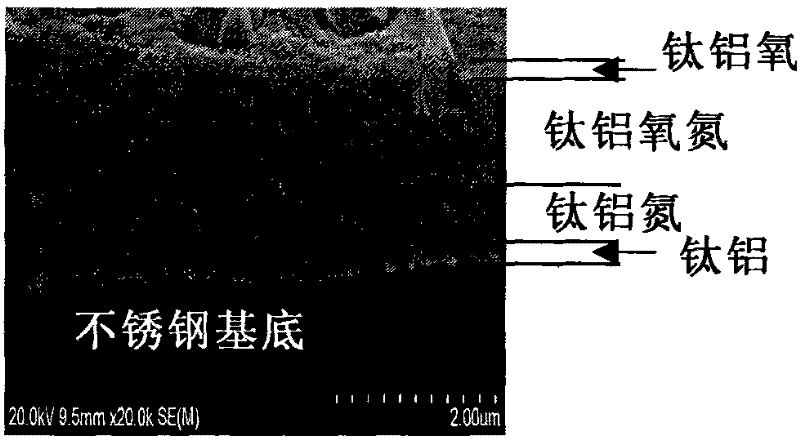

A non-vacuum solar spectrum selective absorption film layer and its preparation method. The absorption film layer is provided with a titanium aluminum film layer, a titanium aluminum nitrogen film layer, a titanium aluminum oxynitride film layer, and a titanium aluminum oxynitride film layer sequentially from the inside to the outside on a stainless steel or copper substrate. The film layer and the titanium aluminum oxide film layer; each film layer is prepared by multi-arc ion plating, and the target material is a titanium aluminum alloy target with an atomic ratio of titanium and aluminum of 50:50; by controlling the argon gas in the multi-arc ion plating atmosphere , nitrogen and oxygen flow to control the composition of nitrogen and / or oxygen in each film layer. The method comprises: (1) selecting a base material and cleaning it; (2) baking the base material in a vacuum sputtering chamber of a multi-target composite coating machine; (3) bombarding the surface of the base material with argon ions; (4) The substrate material is coated; (5) annealing treatment is performed. The film-receiving layer has a high absorption rate α in the solar spectrum range (0.3-2.5 microns), a very low emissivity ε in the infrared region (2-50 microns), has high-temperature oxidation resistance, and meets the requirements of high-temperature utilization of solar energy. Require.

Owner:GRIMAT ENG INST CO LTD

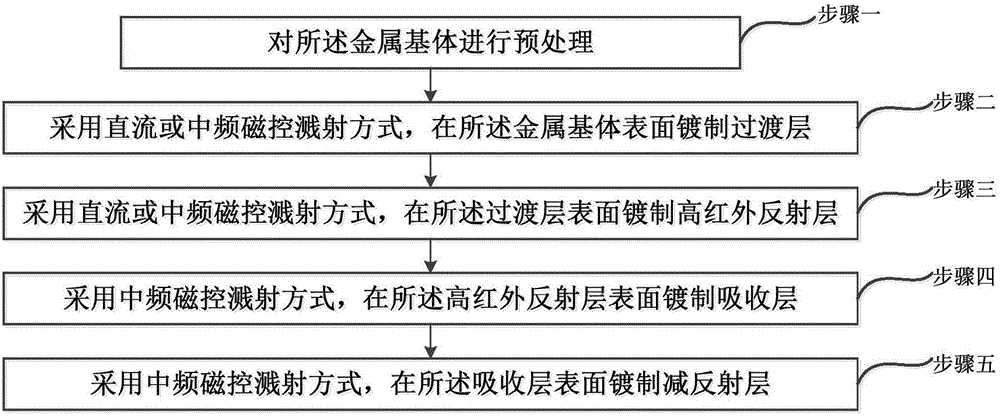

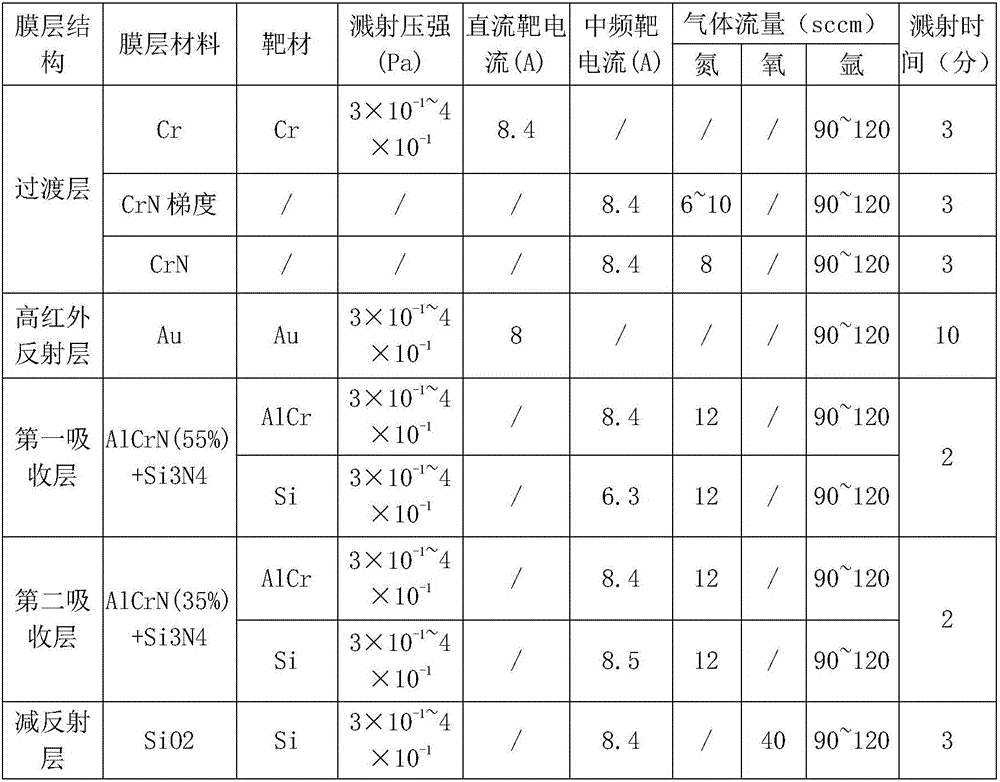

Tower-type heat collector light-thermal conversion coating and preparation method thereof

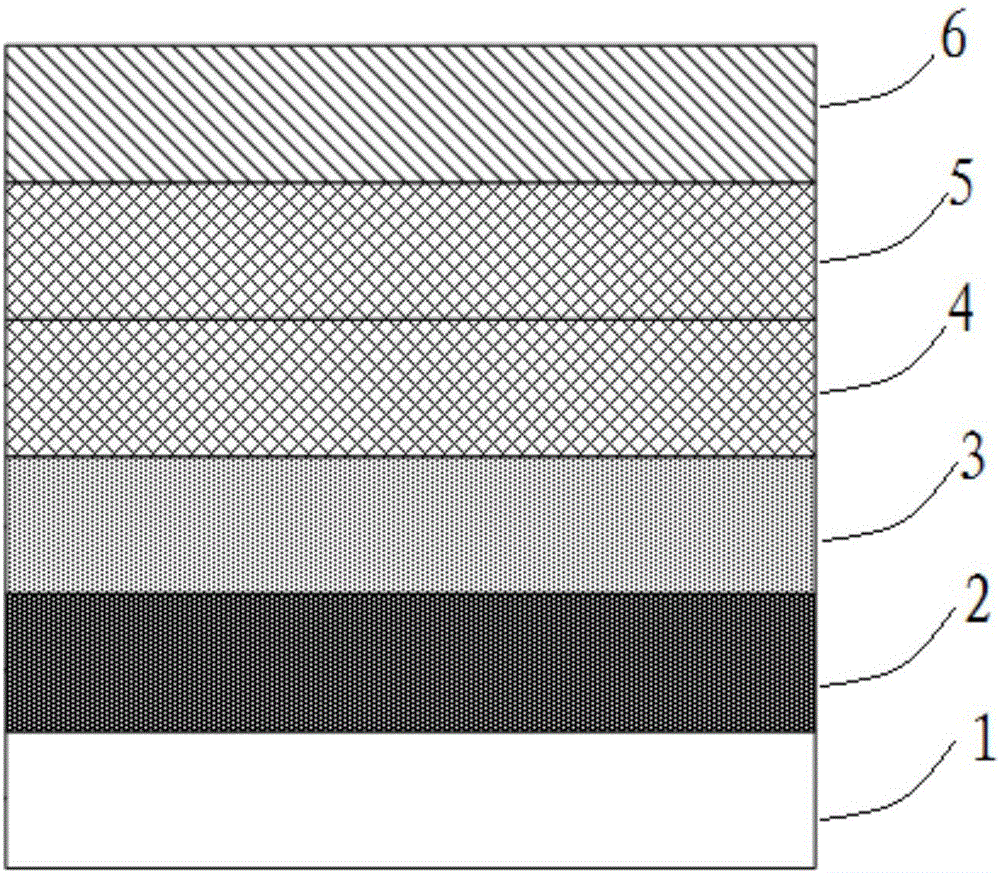

InactiveCN106679202AHas high temperature resistance and oxidation resistanceHigh temperature application requirementsSolar heat devicesVacuum evaporation coatingHigh absorptionLow emissivity

The invention relates to the technical field of light-thermal conversion, in particular to a tower-type heat collector light-thermal conversion coating and a preparation method thereof. The invention provides the tower-type heat collector light-thermal conversion coating, which is arranged on a metal matrix, and comprises a transition layer, a high-infrared reflecting layer, and absorbing layer and an emission reducing layer sequentially arranged from inside to outside. The transition layer comprises a metal layer, a compound gradient layer and a compound layer sequentially arranged from inside to outside. The structure is simple, the process is simple and convenient, and the manufacturing cost is low. According to the tower-type heat collector light-thermal conversion coating provided by the invention, the transition layer is coated by adopting a gradual three-layer transition way from the metal layer to the metal compound layer, so that the binding force of the coating and the metal matrix is improved, the service life is long, and the tower-type heat collector light-thermal conversion coating can be applied in high temperature and bad atmospheric environment; and meanwhile, the light-thermal conversion coating provided by the invention has higher absorption rate within a solar spectrum range, has lower emissivity within an infrared region, has the characteristics of high temperature resistance and oxidation resistance, and meets the requirement on solar energy high temperature utilization.

Owner:北京天瑞星光热技术有限公司

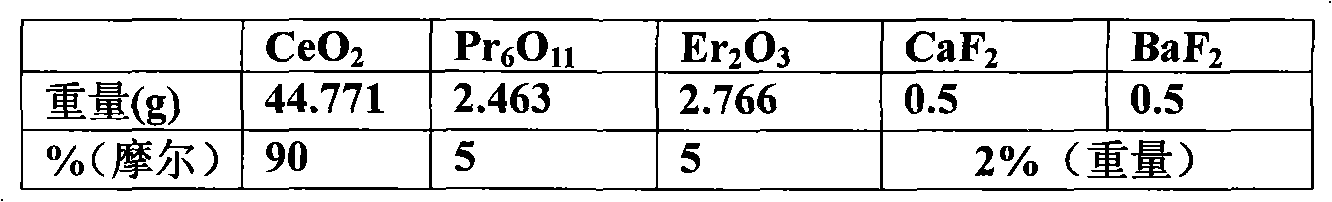

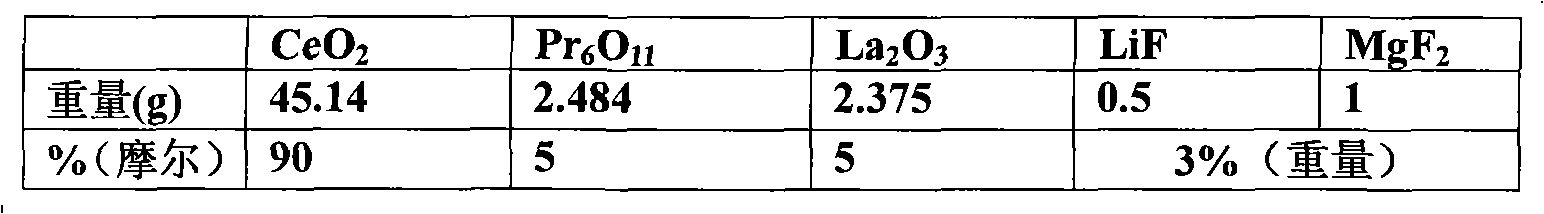

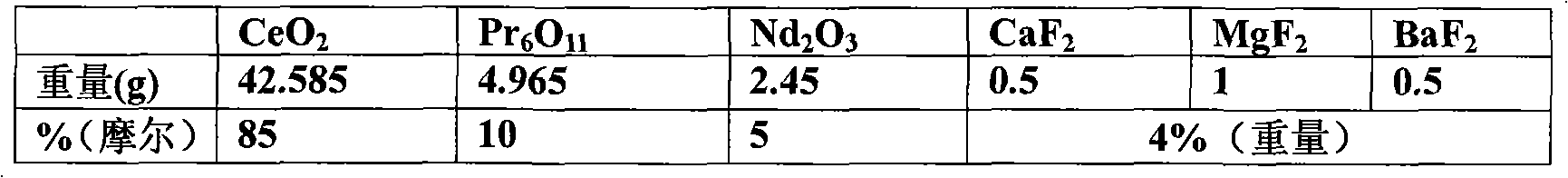

Novel cadmium-free red ceramic pigment color agent

The invention relates to a novel cadmium-free red ceramic paint color, which belongs to the technology field of decorative ceramic materials and the ingredient mol percentage are as follows: 75-98 per cent CeO2, 1-15 per cent Pr6O11 and 1-10 per cent rare earth oxide and the weight percentage of mineralization agent is 2-5 per cent, wherein the rare earth oxide are one of Nd2O3, La2O3, Er2O3 and Sm2O3 and the mineralization agents are two or three of CaF2, NaF, KF, LiF, MgF2 and BaF2 mixing at any proportion. The paint color is used to producing cadmium-free red ceramic paint, which is good in color and has a using temperature of 800-1200 DEG C, which can meet the requirements of high temperature using.

Owner:山东省硅酸盐研究设计院

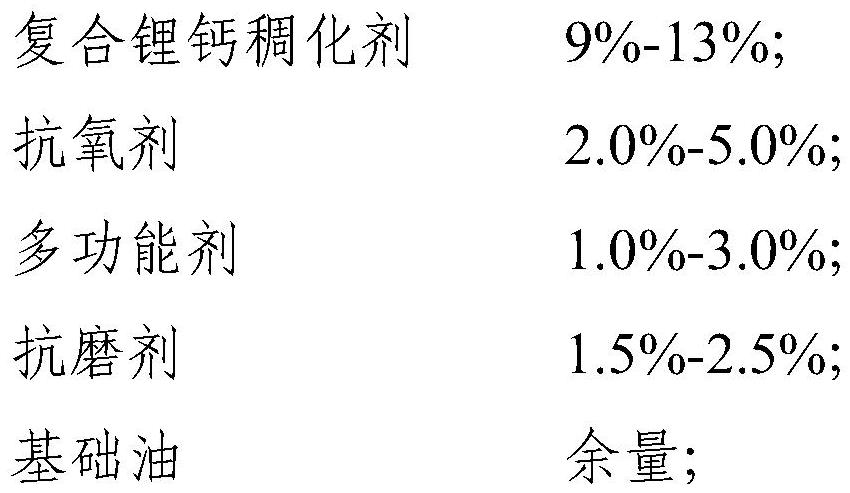

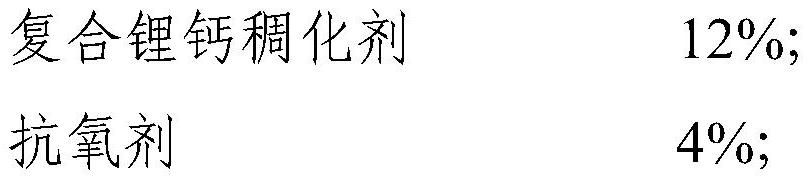

Lubricating grease and preparation method and application thereof

InactiveCN112029558AImprove shear stabilityUniform structurePortable percussive toolsLubricant compositionPolymer scienceAnoxomer

The invention relates to the technical field of lubricating grease, and particularly discloses lubricating grease as well as a preparation method and application thereof. The lubricating grease provided by the invention takes melamine cyanurate as an anti-wear agent, takes a mixture of octyl / butyl diphenylamine and a phenol antioxidant as an antioxidant, and further comprises a composite lithium-calcium thickening agent; wherein the mass ratio of the composite lithium-calcium thickening agent to the anti-wear agent to the antioxidant is 1: (0.1-0.3): (0.2-0.5). The lubricating grease disclosedby the invention is good in oxidation resistance, good in wear resistance, good in anti-shearing performance, good in anti-corrosion protection effect, suitable for friction pair working conditions of large vibration, high temperature and high-frequency sliding, and particularly suitable for lubricating an electric hammer air cylinder.

Owner:CHINA PETROLEUM & CHEM CORP

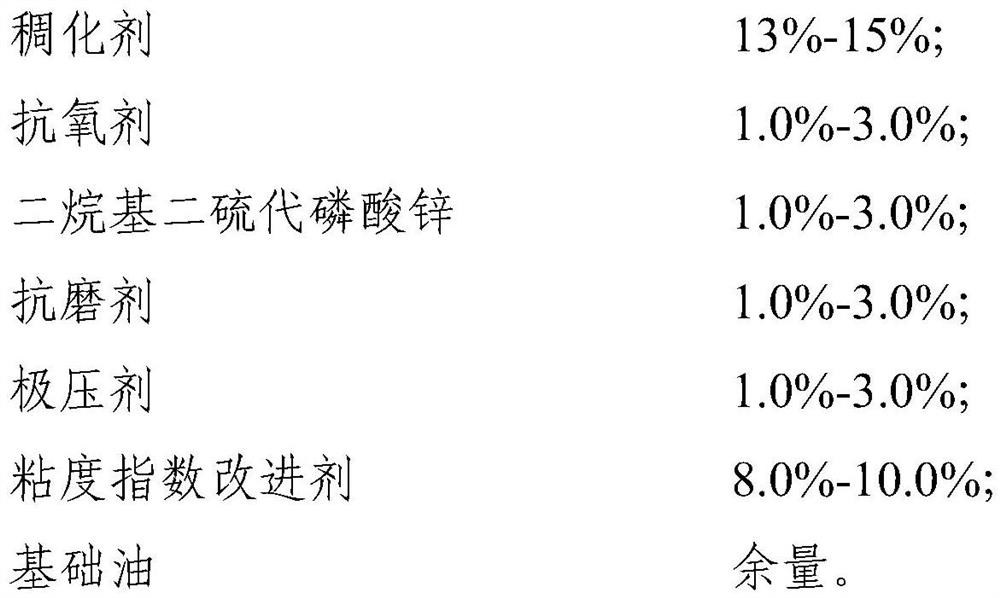

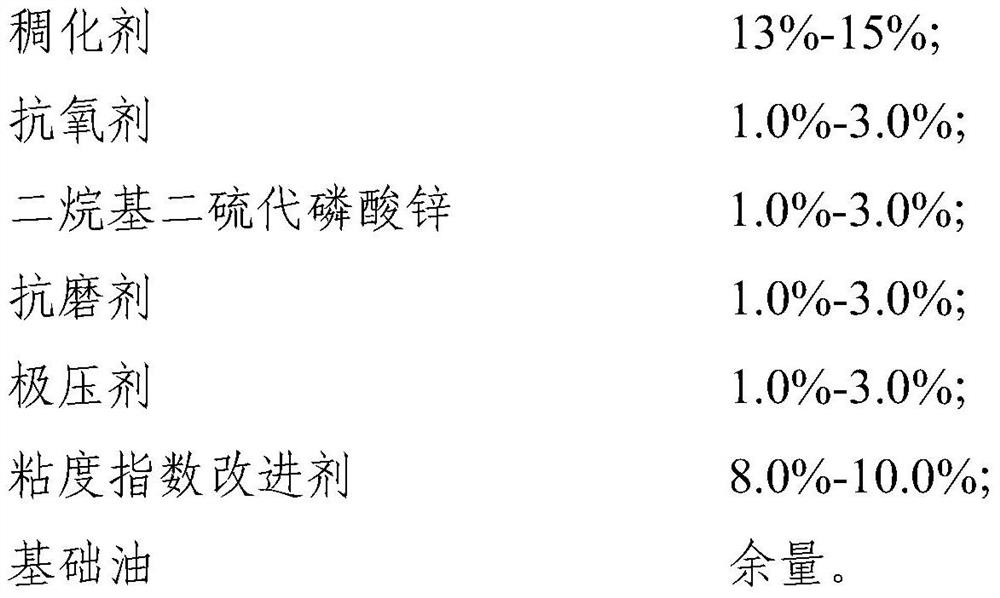

High-power heavy punch cylinder lubricating grease composition and preparation method thereof

PendingCN113430032AImprove high temperature resistanceMeet the requirements of high temperature useLubricant compositionLithium oxideCalcium hydroxide

The invention relates to the field of lubricating oil compositions, in particular to a high-power heavy punch cylinder lubricating grease composition and a preparation method thereof. The lubricating grease composition comprises base oil and a thickening agent, the thickening agent is prepared from calcium hydroxide, lithium hydroxide, 12-hydroxystearic acid and sebacic acid; wherein the mass ratio of the calcium hydroxide to the lithium hydroxide is 1: (7-9); the mass ratio of the sebacic acid to the 12-hydroxystearic acid is 1: (2-4). The lubricating grease composition disclosed by the invention has good wear resistance and high and low temperature performance, has the characteristics of good oxidation resistance, good wear resistance, good anti-corrosion protection effect and the like, can keep excellent comprehensive performance at the temperature of -15 DEG C to 200 DEG C, and can better meet the lubricating working condition of a high-power heavy punch cylinder.

Owner:CHINA PETROLEUM & CHEM CORP

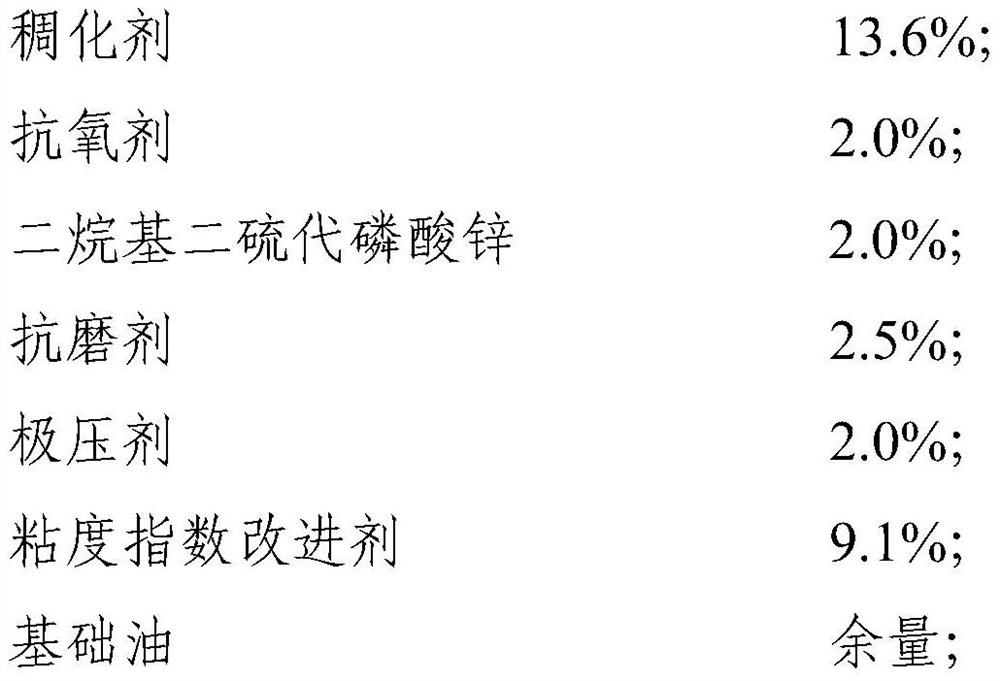

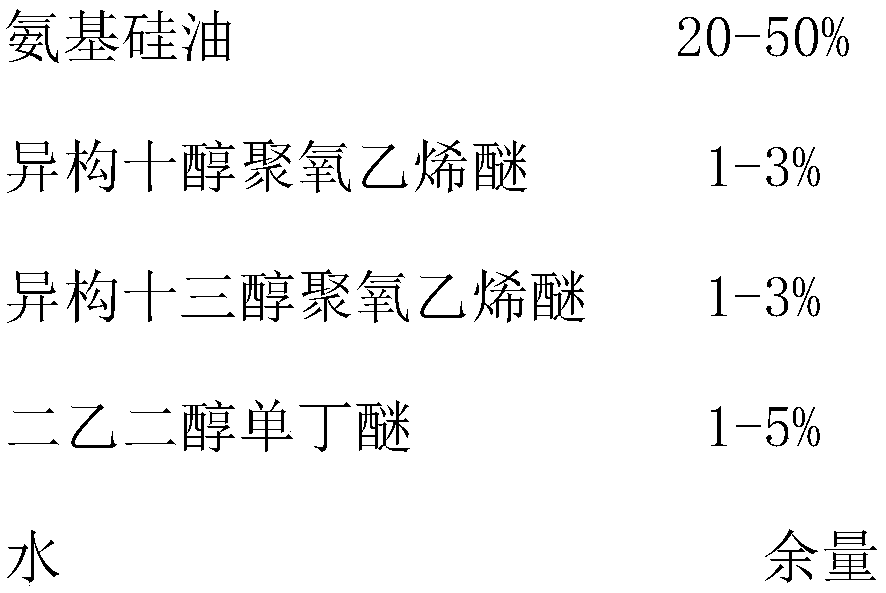

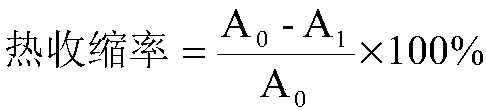

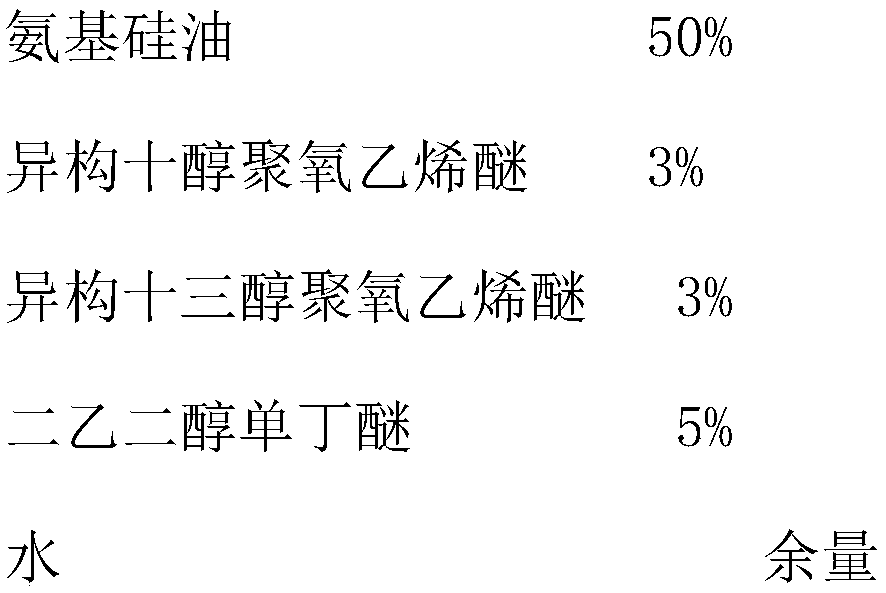

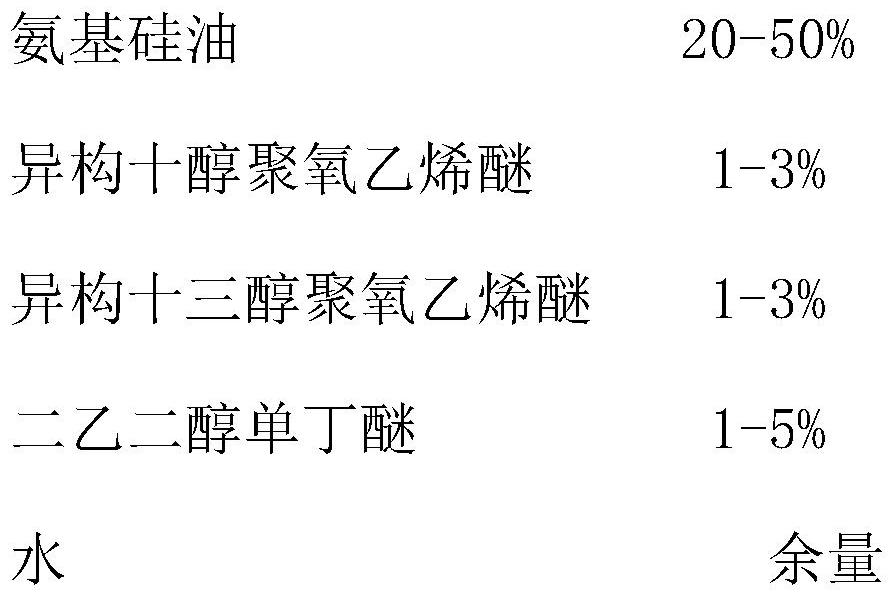

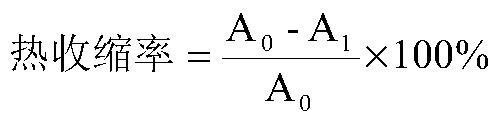

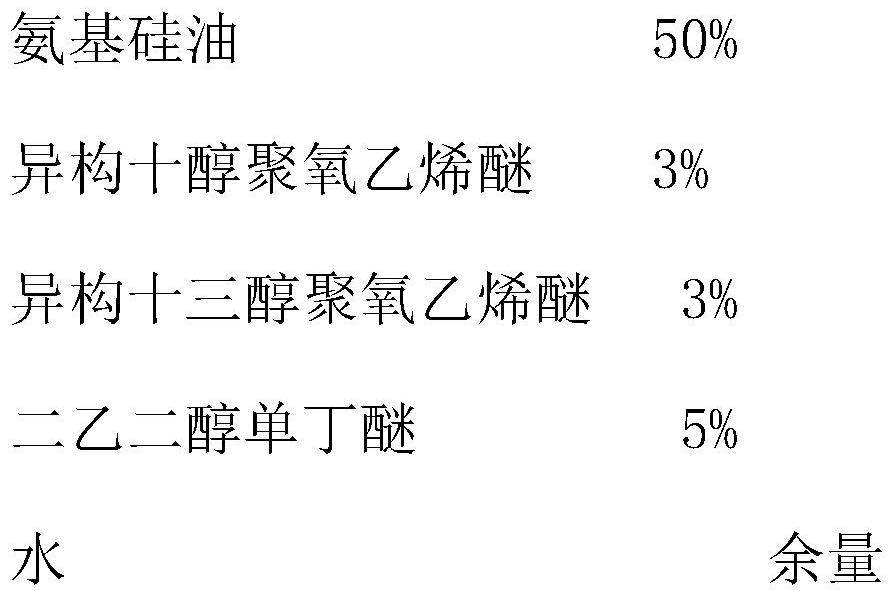

Ultra-low thermal shrinking polyurethane ultrafine fiber base cloth and preparation method thereof

ActiveCN109518467AUltra-low heat shrinkageMeet veneer requirementsPattern makingFibre typesPolyesterFiber

The invention discloses ultra-low thermal shrinking polyurethane ultrafine fiber base cloth and a preparation method thereof. The preparation method of the ultra-low thermal shrinking polyurethane ultrafine fiber base cloth comprises the following steps: impregnating a non-woven fabric formed by needling nylon 6 or polyester and island short fibers prepared from polyethylene or styrene in wet process slurry; then carrying out condensation and washing; extracting polyethylene or styrene in hot methylbenzene to obtain wet cloth; then impregnating the wet cloth in an oiling solution to knead grains continuously and dry to obtain the ultra-low thermal shrinking polyurethane ultrafine fiber base cloth. The oiling solution contains amino silicone oil, isodecanol polyoxyethylene ether, iso-tridecanol polyoxyethylene ether, butyl diglycol acetate and water. The ultra-low thermal shrinking polyurethane ultrafine fiber base cloth has an ultralow thermal shrinking rate, the thermal shrinking value of a base cloth finished product is 0.1-1.5%, and the crease is smooth. The ultra-low thermal shrinking polyurethane ultrafine fiber base cloth can meet the high-temperature using demand and can meet the high-temperature dry method veneering demand.

Owner:江苏华峰超纤材料有限公司

High-strength heat-resistant magnesium alloy

The invention discloses a high-strength heat-resistant magnesium alloy and belongs to the technical field of magnesium alloy materials. The high-strength heat-resistant magnesium alloy comprises the following components in percentage by mass: 5.5-6.2% of Y, 0.5-0.7% of Ce, 0.4-0.6% of Zr, 0.2-0.5% of Sb and the balance of Mg and inevitable impurities. The magnesium alloy is prepared by taking pure Mg and Sb as well as intermediate alloys of Mg-25%Y, Mg-25%Ce and Mg-25%Zr as raw materials, smelting and casting to obtain magnesium alloy ingots at first, then performing solid-solution treatment on the magnesium alloy ingots sequentially for 8 hours at 525 DEG C, and performing aging treatment for 16 hours at 225 DEG C. The magnesium alloy disclosed by the invention has relatively high room-temperature and high-temperature strength, and has relatively good strength stability at 200-300 DEG C.

Owner:HENAN UNIV OF SCI & TECH

Preparation method of double-layer heat-insulating and wave-permeable composite structural member

The invention discloses a method for preparing a double-layer wave-permeable heat proofing and insulating composite structural part. The structural part comprises an inner heat insulation material and an outer heat-proof +material. The method includes steps of preparation of the outer heat-proof material, preparation of silicon oxide hollow microspheres, preparation of chopped fiber reinforced silicon oxide hollow microsphere slurry, casting of the chopped fiber reinforced silicon oxide hollow microsphere slurry and thermal treatment of a structural part blank material. Quartz fiber reinforced quartz composite ceramic serves as the outer heat-proof material, chopped fiber reinforced silicon oxide hollow microsphere ceramic serves as the inner heat insulation material, compact combination of the inner and outer materials is realized by means of slurry casting and high-temperature sintering moulding, and integration of advantageous performances of high temperature resistance, heat proofing, heat insulation, wave permeability and the like is realized.

Owner:湖北三江航天江北机械工程有限公司

High-temperature fenico magnetostrictive alloy and preparation method thereof

ActiveCN103556005BImprove magnetic propertiesMeet the requirements of high temperature useChemical compositionCurie temperature

The invention discloses a high-temperature FeNiCo magnetostrictive alloy and a preparation method thereof. The weight percent of the chemical composition of the alloy is: Ni: 30.0-55.0%, Co: 1.0-22.0%, Cr: 1.0-3.5%, Mo: 1.0- 3.5%, Ti: 1.0-3.0%, Al: 0-2.0%, B: 0-0.006%, and the balance is Fe. The high-temperature magnetostrictive alloy of the invention has a high Curie temperature, good magnetic properties and a large saturation magnetostriction coefficient in a wide temperature range, and can meet the high-temperature use requirements of high-precision instruments and meters.

Owner:CHONGQING MATERIALS RES INST

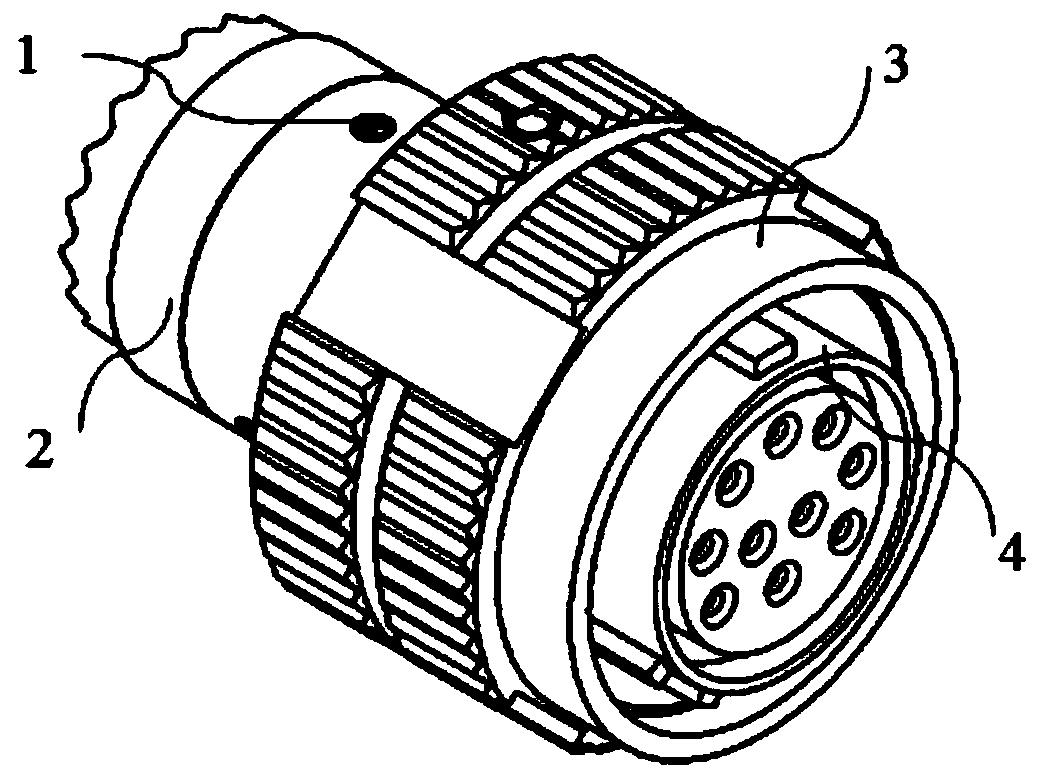

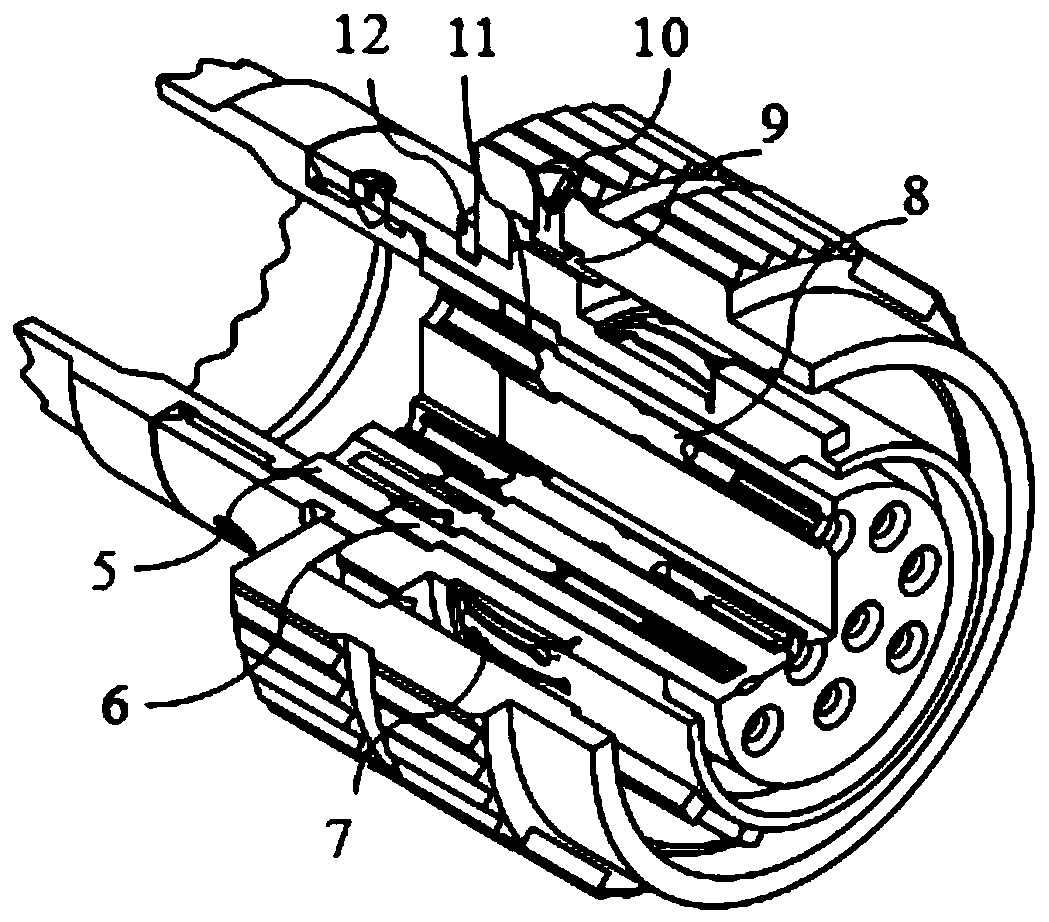

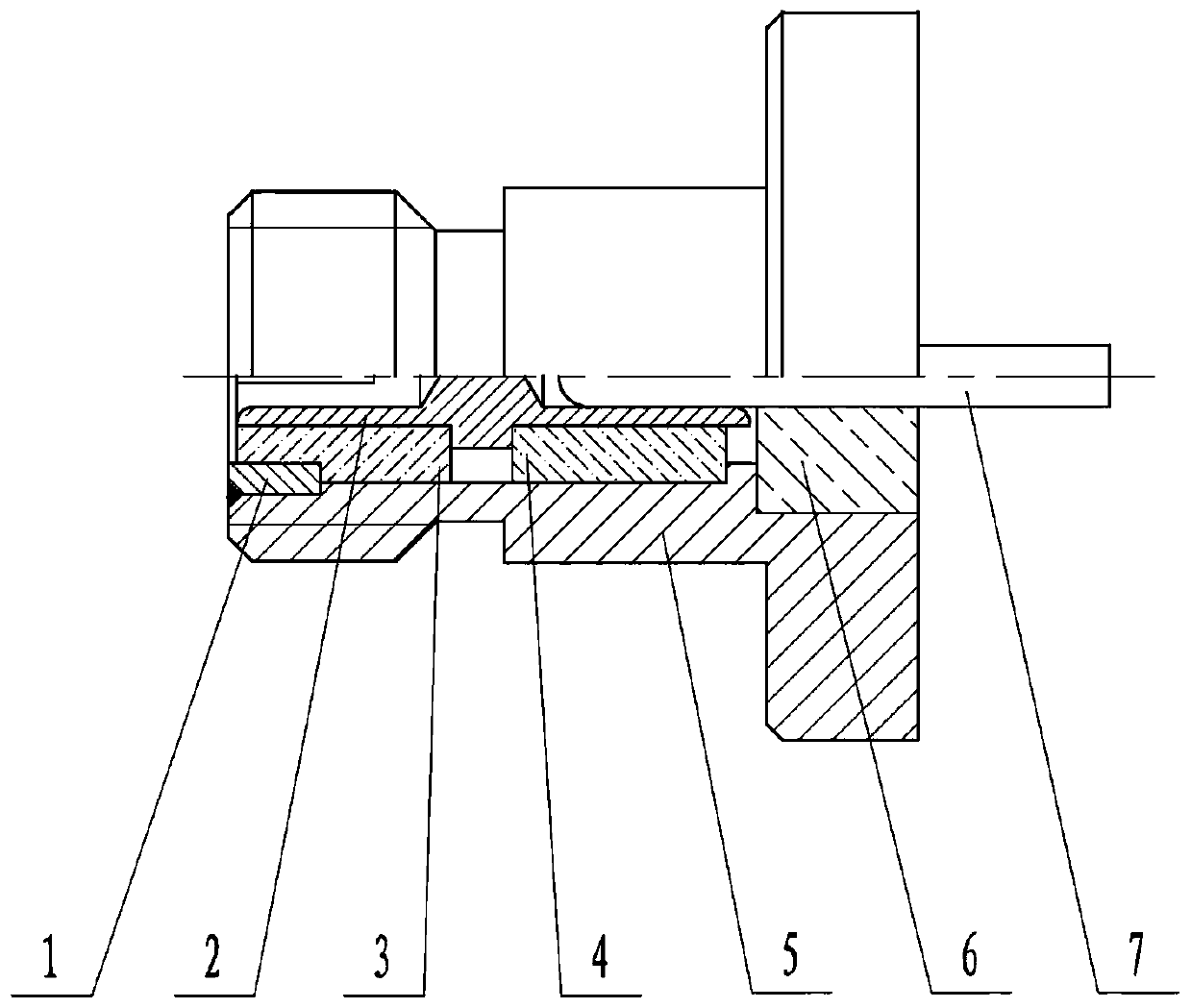

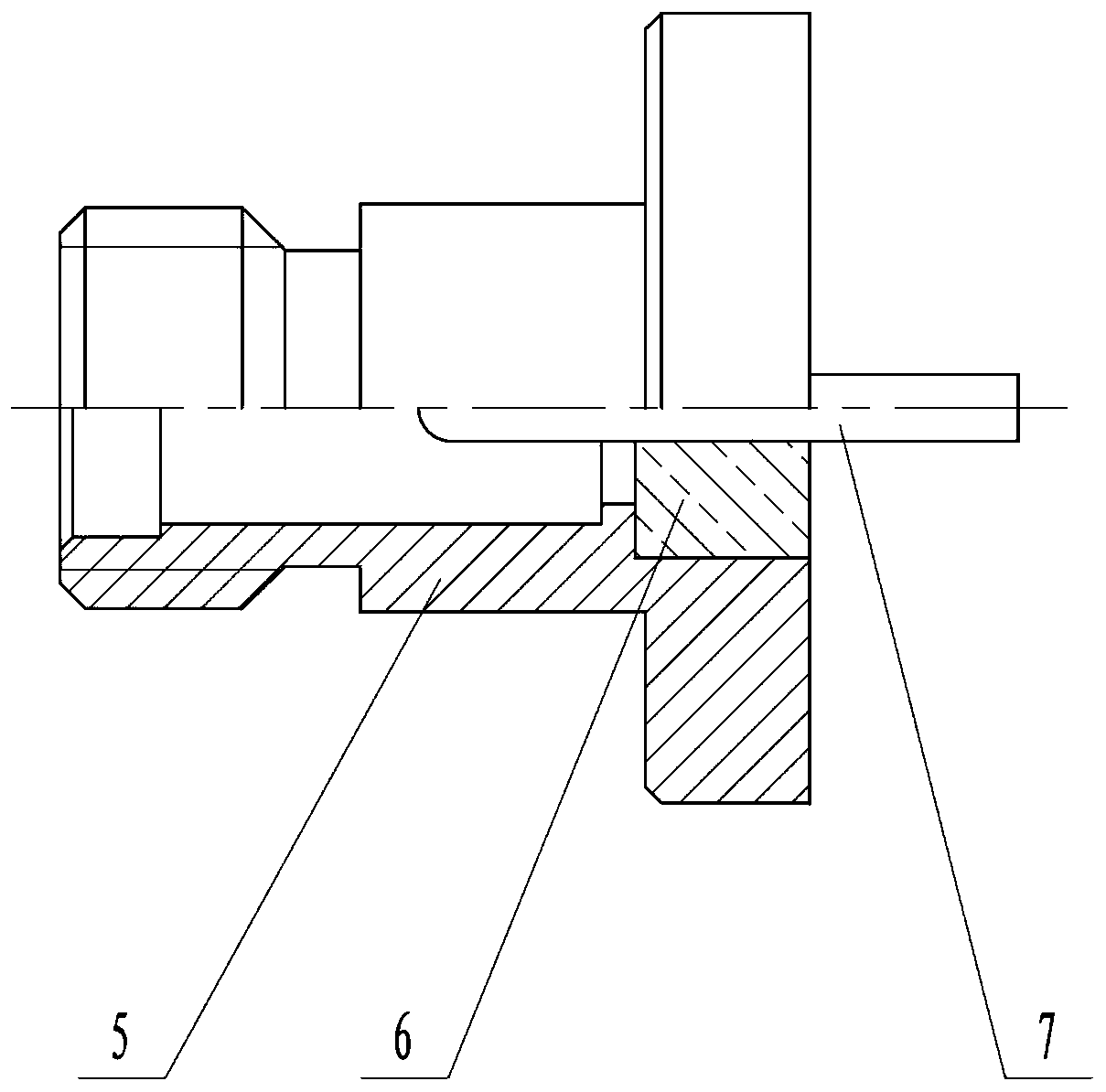

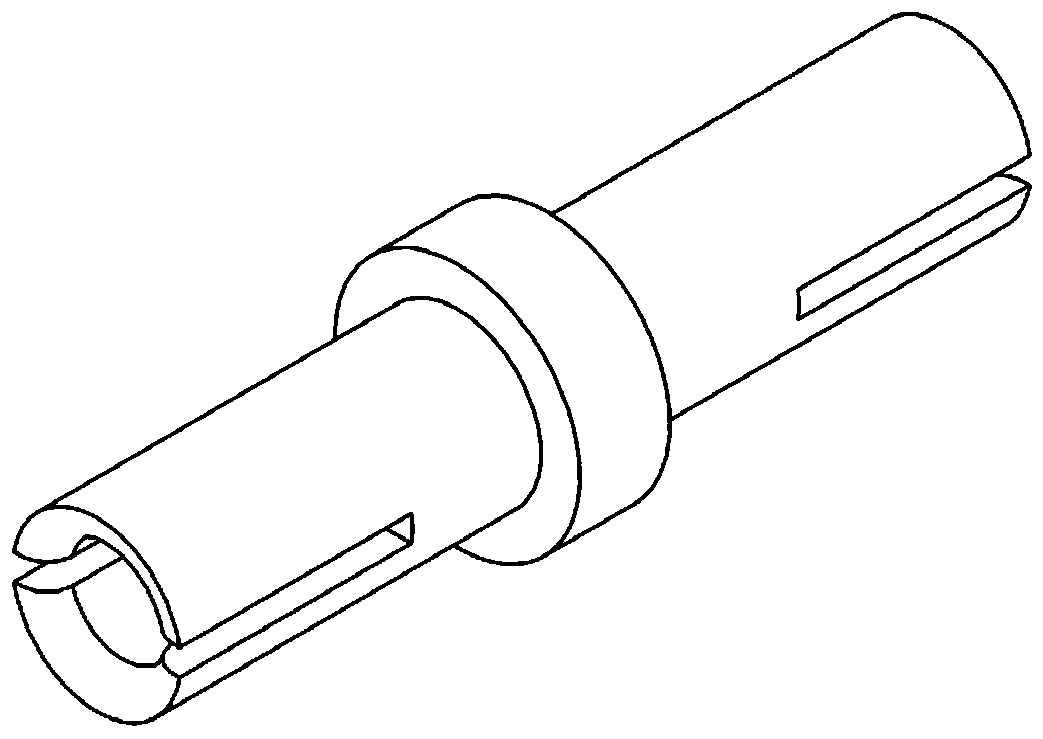

A light-weight high-temperature electrical connector with detachable contacts

ActiveCN108987994BMeet reliabilityLow densitySecuring/insulating coupling contact membersCoupling contact membersElectrical connectionEngineering

The invention provides a detachable lightweight high-temperature electrical connector comprising a base assembly, a screw sleeve assembly and a housing assembly. The base assembly, the screw sleeve assembly and the outer shell assembly are arranged from the inside to the outside in sequence; The base assembly comprises a lower base and an upper base, wherein a contact part and a stay spring ring are arranged in the upper base, one end of the upper base is buckled with the lower base, and the other end of the lower base is provided with a nut; The support spring coil is arranged at both ends ofthe contact piece; The peripheral ring of the support spring coil is a support barb structure, and the contact piece is fixed by the support barb; The screw sleeve assembly is installed from the tailend of the shell part and fixed by a retaining ring; The nut presses the base assembly into the housing joint. The invention can meet the requirements of high-temperature use, and the shell materialdensity is small, and the weight reduction purpose can be achieved, and the weight loss is about 30% compared with the existing high-temperature products with the same specification; The contact piececan realize the disassembly function and satisfy the reliability of the assembly between the parts.

Owner:GUIZHOU SPACE APPLIANCE CO LTD

Proton exchange membrane and preparation method thereof

ActiveCN103236557BSimple methodEasy to operateFinal product manufactureSolid electrolyte fuel cellsPhysical chemistryPhosphoric acid

Owner:DONGHUA UNIV

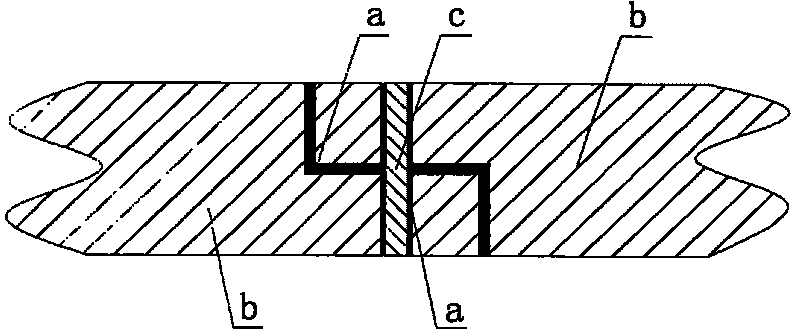

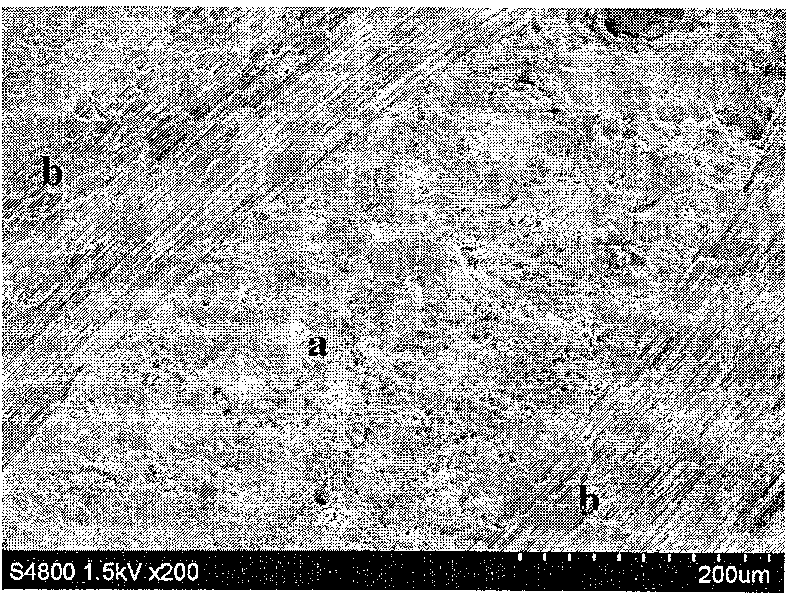

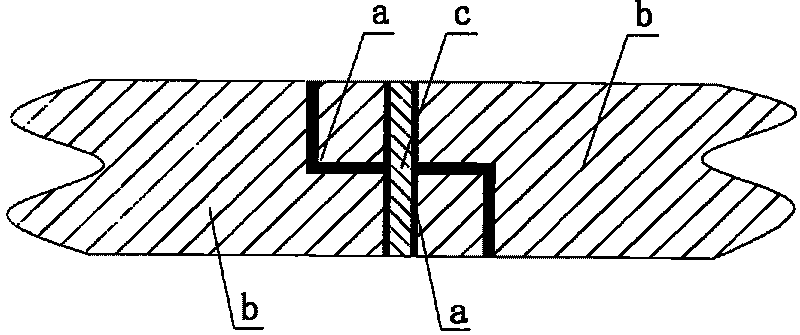

SiC based composite material component and on-line jointing preparation method thereof

The invention discloses a SiC matrix composite material element and the online connection and preparation method. The element is connected into a whole by the connecting piece through the connection layer at the connector lug, which is characterized in that the component of the connection layer is pure SiC material and the SiC material uses the mix solution of PCS and divinylbenzene as the adhesive, and uses SiC fine power as the packing medium, and can be achieved though preceramic polymer pyrolysis; SiC matrix composite material element with stronger connection strength can be gained throughthe auxiliary connection and the reinforcement of the fastener of SiC matrix composite material. The SiC matrix composite material element and the online connection and the preparation method has theadvantages of simple and practical preparation method, low cost, good thermostable performance and mechanics compatibility, good structural integrity. The connecting preparation method is especiallysuitable for the connection formation and preparation of large-scale complex components.

Owner:NAT UNIV OF DEFENSE TECH

Solar spectrum selective absorbing coating and preparation method thereof

ActiveCN102122006BSolve high temperature oxidationChange colorVacuum evaporation coatingSputtering coatingHigh absorptionLow emissivity

Owner:GRIMAT ENG INST CO LTD

Non-vacuum solar spectrum selective absorption coating and preparation method thereof

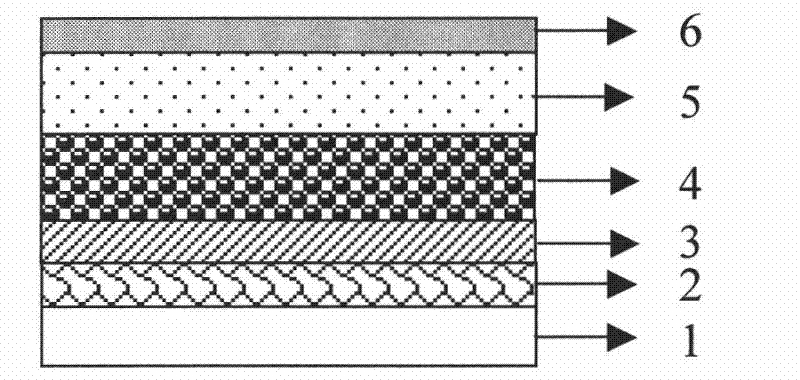

ActiveCN102121757BHigh absorption rate αLow high temperature oxidation resistanceSolar heat devicesLayered productsIr reflectionLow emissivity

The invention relates to a non-vacuum solar spectrum selective absorption coating and a preparation method thereof. The preparation method comprises the following steps: (1) selecting copper or stainless steel with low infrared emissivity as a base material; (2) selecting oxide resistant to high-temperature oxidation, nitride and complex or doped oxide as a film material, wherein a metal or an alloy serves as a bonding force increased layer, metal nitride or pure metal serves as a high infrared reflecting layer, an absorption layer is composed of two conducting particle ceramic layers with different metal nitride conducting particle volume fractions, and aluminium nitride and aluminium oxide serve as an antireflection layer; (3) controlling the components and contents of different film materials by controlling gas flow and sputtering power; (4) cleaning the base material before the base material is placed into a vacuum chamber, and carrying out argon ion bombarding on the surface of the base material before sputtering is carried out; and (5) obtaining a multilayer coating, wherein the thickness of the coating is less than 500nm, and the coating has high absorption rate alpha (0.9-0.97) in the solar spectrum range (0.3-2.5microns) and has extremely low emissivity epsilon (0.02-0.18) in the infrared region (2.5-50microns).

Owner:GRIMAT ENG INST CO LTD

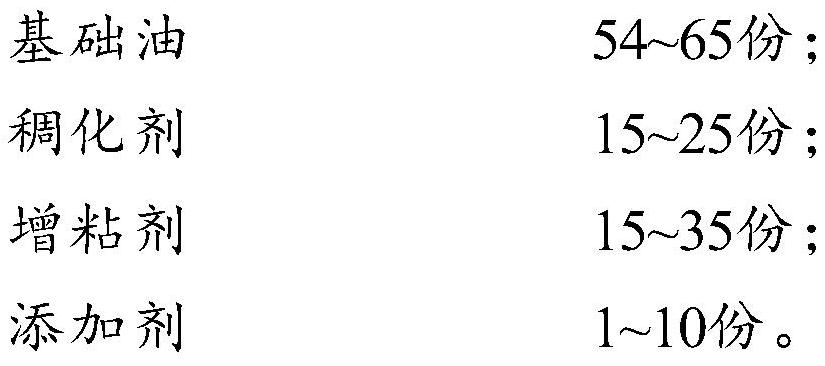

Steel wire rope lubricating grease composition and preparation method thereof

PendingCN113717773ASolve the dripping problemMeet the requirements of high temperature useLubricant compositionBase oilTackifier

The invention provides a steel wire rope lubricating grease composition which comprises the following components, by weight: 54-65 parts of base oil, 15-25 parts of a thickening agent, 15-35 parts of a tackifier, and 1-10 parts of an additive. The steel wire rope lubricating grease with a high dropping point is obtained by optimally proportioning the types and dosages of the base oil, the thickening agent, the tackifier and the additive, and the problem that the lubricating grease drips at a high temperature is solved. The dropping point of the steel wire rope lubricating grease can reach over 95 DEG C, so that the high-temperature use requirement is met. The invention also provides a preparation method of the steel wire rope lubricating grease composition.

Owner:CHINA PETROLEUM & CHEM CORP

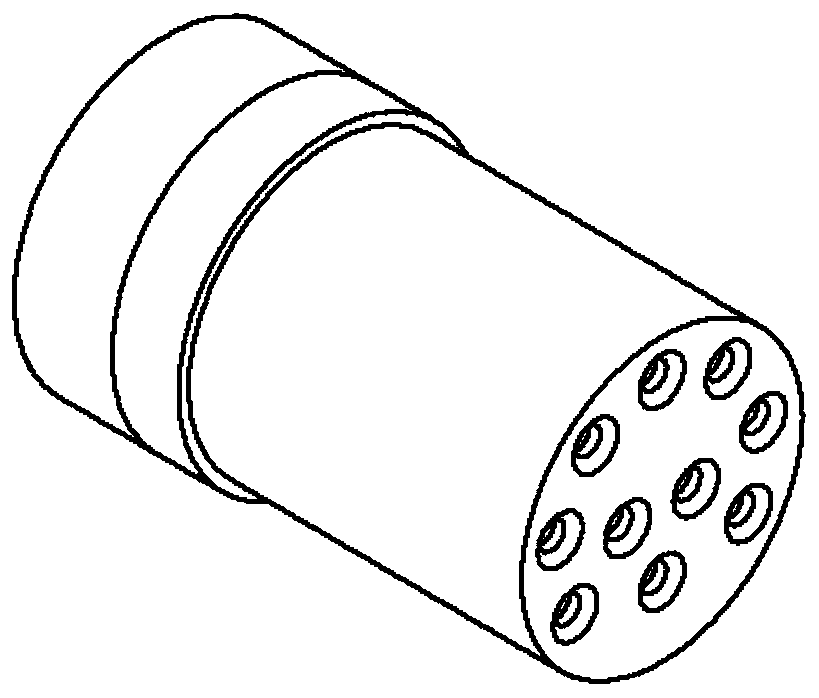

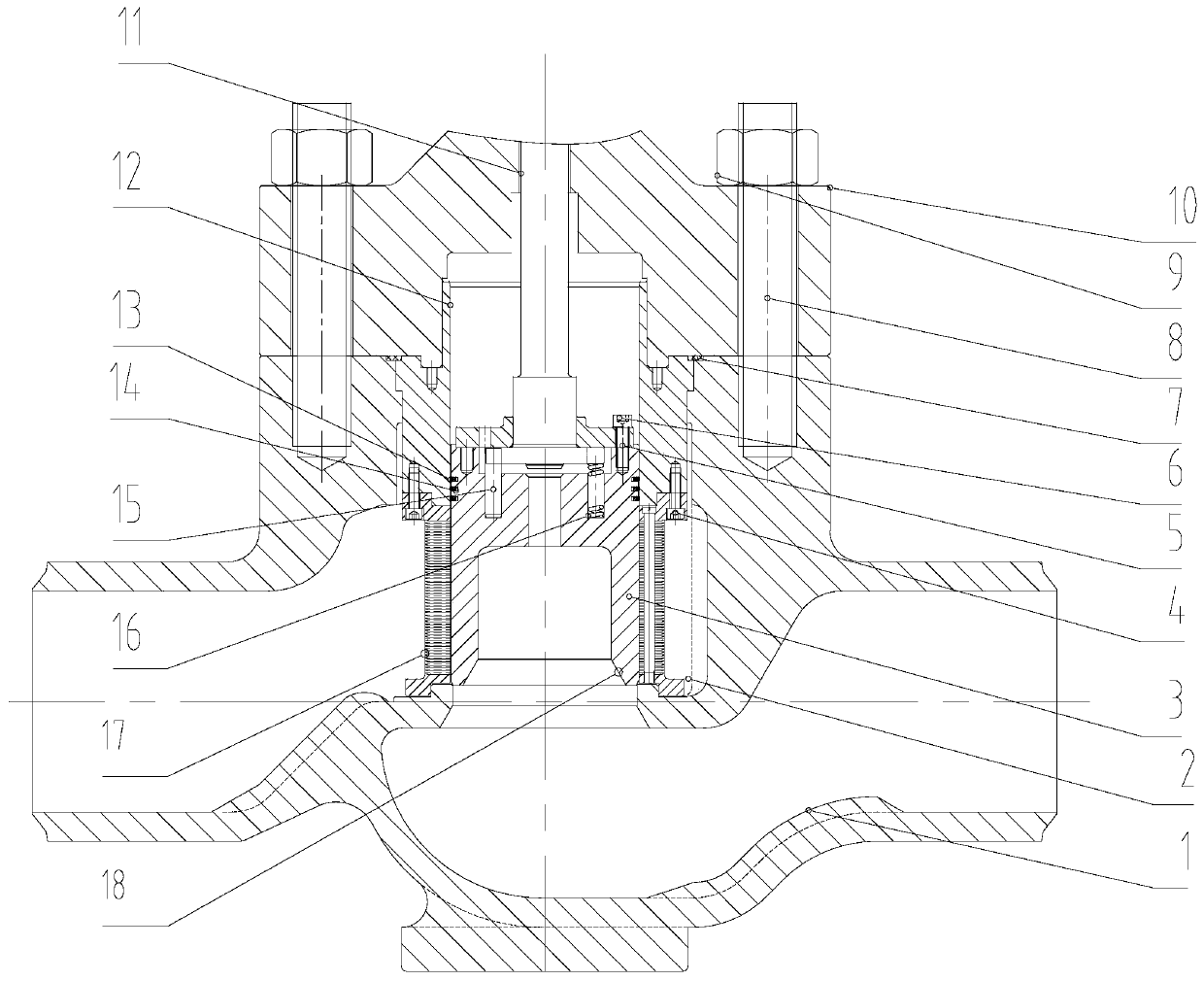

A high temperature sealed connector and its manufacturing method

ActiveCN109841983BIncrease temperatureMeet the requirements of high temperature useContact member assembly/disassemblyCoupling contact membersEngineeringStructural engineering

The invention discloses a high-temperature sealed connector and a manufacturing method thereof. The connector comprises a housing provided with a through hole, a contact part is arranged in the through hole of the housing and comprises an insertion hole contact member and a pin inserted into the insertion hole contact member, two ends of the insertion hole contact member are provided with split slot insertion holes, the pin is inserted into one end of the insertion hole contact member, the other end of the insertion hole contact member is level with an end face of the housing, the pin passes through a ring body made of a ceramic medium, the ring body is inserted into a tail stepped hole of the housing, the pin, the ring body and the housing are welded by a ceramic-metal brazing technique to form a sealed body, a stepped hole mouth part of the housing fixes a fixed ring into the stepped hole by a laser welding process, the fixed ring is level with an end face of the housing, and the outer circle surface of the fixed ring cooperates with the inner hole surface of the housing. The connector of the invention satisfies the requirement of use in a high-temperature environment of 600 DEGC and has sealing performance.

Owner:SICHUAN HUAFENG ENTERPRISE GRP

Suspended labyrinth sleeve structure

PendingCN109780314AStrong interchangeabilityImprove economic efficiencyValve members for absorbing fluid energyLift valveEngineeringHigh pressure

The invention relates to a suspended labyrinth sleeve structure, and belongs to the technical field of fluid control valves. The suspended labyrinth sleeve structure comprises a valve body, an upper cover, a sleeve assembly and a valve core assembly; an inlet flow passage and an outlet flow passage are distributed on the valve body and are correspondingly arranged at the two ends of the valve body; the sleeve assembly is mounted on an upper cavity convex table of the valve body; the valve core assembly is arranged in the sleeve assembly; the valve core assembly adopts a pilot valve core structure, and can linearly move along the inner wall of the sleeve; an upper cover is arranged in the axial direction of the outlet flow passage of the valve body; a gasket is arranged between the valve body and the upper cover; and the valve body and the upper cover are connected into a whole through studs and nuts. The suspended labyrinth sleeve structure can effectively achieve the effect of pressure drop, the service life of the whole sleeve assembly is prolonged, a high temperature and high pressure can be borne, and the working conditions of a high pressure difference and a high sealing gradecan be adjusted. The suspended labyrinth sleeve structure is relatively low in machining precision requirement, the thrust of a required actuator is small and the sealing effect is reliable.

Owner:WUXI SMART AUTO CONTROL ENG CO LTD

A kind of polyimide paper and preparation method thereof

ActiveCN106638114BLow dielectric constantEnhanced physical entanglementPlastic/resin/waxes insulatorsPaper/cardboardFiberRaw material

Owner:BEIJING UNIV OF CHEM TECH

Ultra-low thermal shrinkage polyurethane superfine fiber base cloth and preparation method thereof

ActiveCN109518467BUltra-low heat shrinkageMeet veneer requirementsPattern makingFibre typesDiethylene glycol monobutyl etherPolyester

The invention discloses an ultra-low thermal shrinkage polyurethane microfiber base cloth and a preparation method thereof. The preparation method of the ultra-low thermal shrinkage polyurethane ultrafine fiber base cloth comprises the following steps: making nylon 6 or polyester, polyethylene or styrene into The non-woven fabric formed by sea-island short fiber is impregnated in wet slurry, then coagulated and washed with water, and then the polyethylene or styrene is decremented in hot toluene to obtain a wet cloth, and then the wet cloth is impregnated Continuous kneading and drying in the oiling solution can obtain the ultra-low heat shrinkage polyurethane microfiber base cloth; the oiling solution contains amino silicone oil, isomerized decanol polyoxyethylene ether, isomerized decanol polyoxyethylene ether, isomerized decanol Triol ethoxylates, diethylene glycol monobutyl ether and water. The invention has an ultra-low thermal shrinkage rate, the thermal shrinkage value of the finished base fabric is 0.1-1.5%, and the features of fine creases can meet the requirements of high-temperature use and high-temperature dry veneering.

Owner:江苏华峰超纤材料有限公司

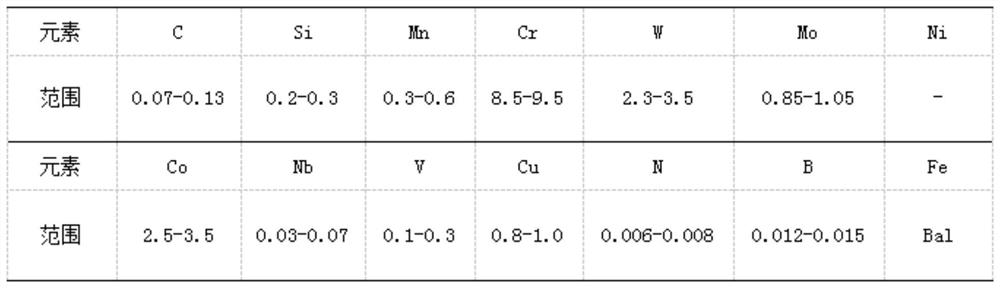

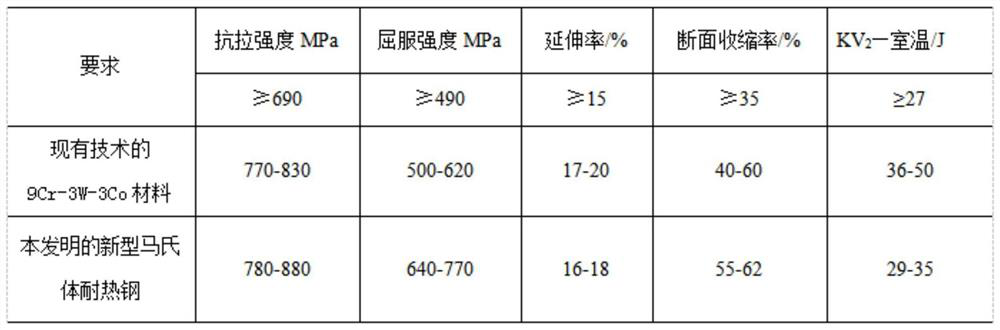

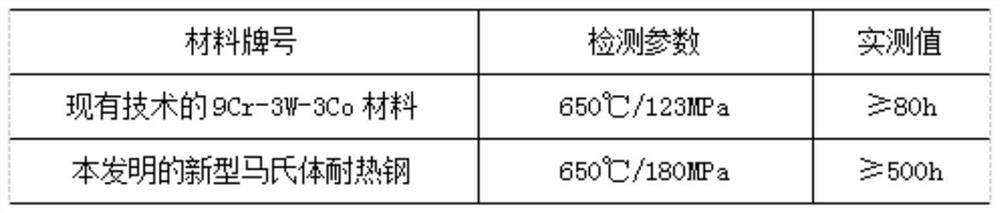

Martensite heat-resistant steel

PendingCN113789484AMeet the requirements of high temperature useTypical lath martensitic structureMo elementMartensite

The invention belongs to the technical field of casting, and mainly relates to a component design of a novel 9Cr-3W-3Co martensite heat-resistant steel material. Ni element is added in a component design process, and on the premise that the plasticity of the material is not reduced, the strength of the material is increased, and the room-temperature mechanical property of the material is improved; more trace elements such as B and N are added, so that the B element is greatly distributed on the M23C6 carbide after heat treatment, and the high-temperature endurance strength of the material is improved; a trace amount of Mo element is added, so that the effects of solid solution strengthening and precipitation strengthening are achieved; and the content requirement of Cu element is lowered, and the brittleness tendency of the Cu element is reduced.

Owner:KOCEL STEEL

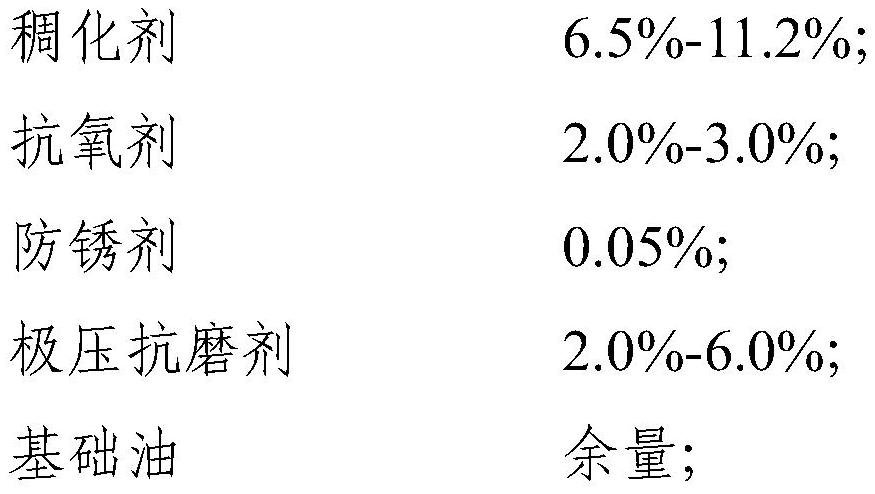

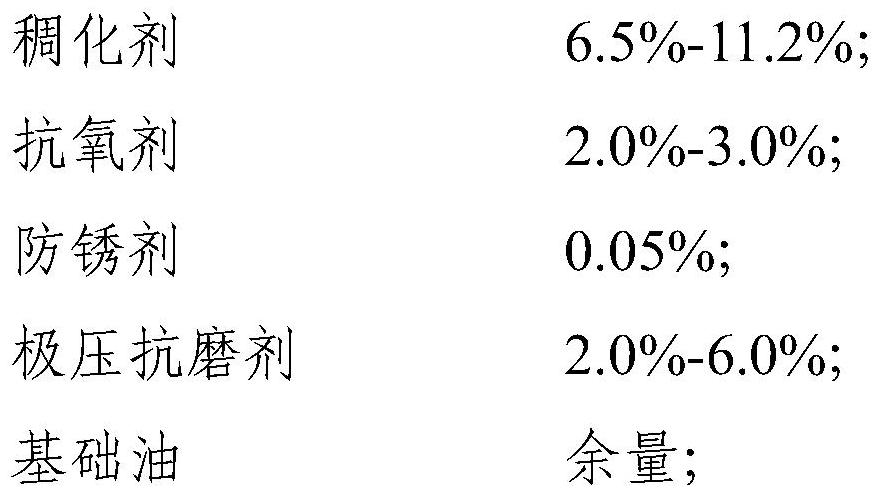

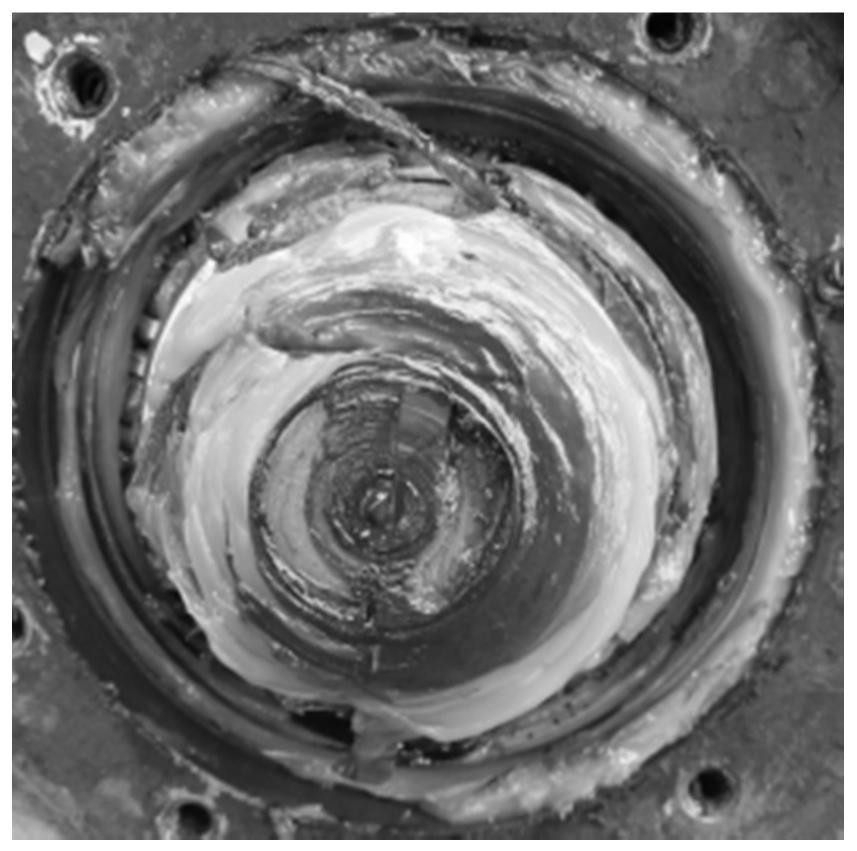

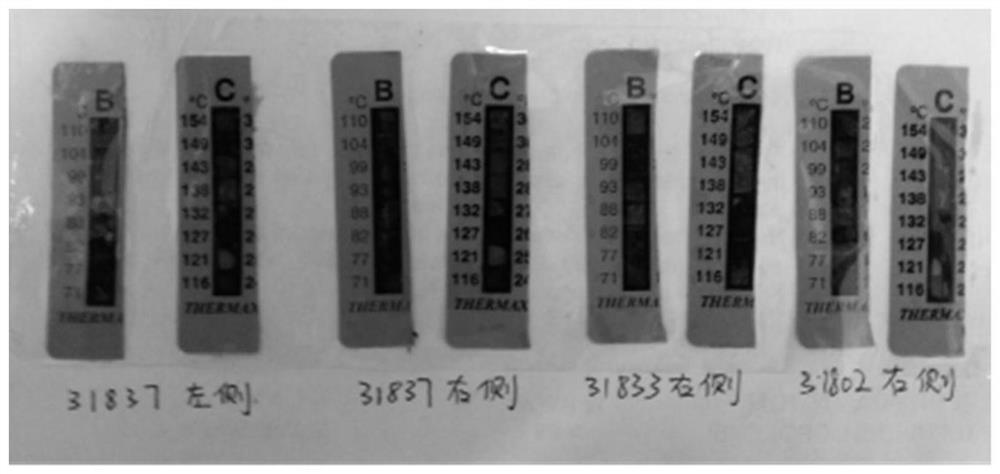

Urea-based lubricating grease composition for electric hammer cylinder and preparation method thereof

PendingCN112522008AImprove shear stabilityImprove antioxidant capacityLubricant compositionAnilineBase oil

The invention provides a urea-based lubricating grease composition for an electric hammer cylinder. The urea-based lubricating grease composition comprises the following components by mass: 6.5%-11.2%of a thickening agent, 2.0%-3.0% of an antioxidant, 0.05% of an antirust agent, and 2.0%-6.0% of an extreme-pressure anti-wear agent, with the balance being base oil, wherein the thickening agent isprepared by subjecting raw materials consisting of octylamine, aniline and diphenylmethane diisocyanate to an addition reaction, and the viscosity range of the base oil at 40 DEG C is 168-180 mm<2> / s.According to the urea-based lubricating grease composition for the electric hammer cylinder, the shear stability of lubricating grease is improved, the lubricating grease has the characteristics of good oxidation resistance, good wear resistance, good corrosion resistance, good protection effect and the like, the lubricating working condition of the electric hammer cylinder can be better met, theuse temperature range of the lubricating grease is 20-180 DEG C, and the lubricating grease has wide popularization value.

Owner:CHINA PETROLEUM & CHEM CORP

High-temperature plateau mountain vehicle hub bearing lubricating grease and preparation method thereof

ActiveCN111607449AGood high temperatureGood rubber compatibilityRolling resistance optimizationLubricant compositionMineral oilBase oil

The invention relates to high-temperature plateau mountain vehicle hub bearing lubricating grease and a preparation method thereof. The high-temperature plateau mountain vehicle hub bearing lubricating grease comprises the following components in percentage by weight: 70-90% of base oil, 5-20% of a thickening agent, and 1.5-12.5% of an additive, wherein the base oil is mineral oil with the viscosity of 180-220 mm<2> / s at 40 DEG C, and the thickening agent is a composite lithium-based thickening agent. According to the full mineral oil type high-temperature plateau mountain vehicle hub bearinglubricating grease provided by the invention, on the premise of excellent high-temperature performance, extreme-pressure anti-wear performance and water resistance, the production cost is controlled,the problem of fat loss of existing hub bearing lubricating grease is solved, and the hub bearing lubricating grease can be used within the temperature range of -30 DEG C to 180 DEG C for a long timeand can meet the use requirements of various vehicle hub bearings in areas (including plateau mountainous regions) at -30 DEG C or above.

Owner:军事科学院系统工程研究院军事新能源技术研究所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com