High-power heavy punch cylinder lubricating grease composition and preparation method thereof

A lubricating grease composition, high-power technology, applied in the direction of lubricating composition, petroleum industry, etc., can solve the problems of poor adhesion of lubricating grease, lubrication failure, insufficient anti-wear performance, etc., to achieve a balance of fluidity and adhesion Good performance, meet the lubrication conditions, good anti-oxidation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

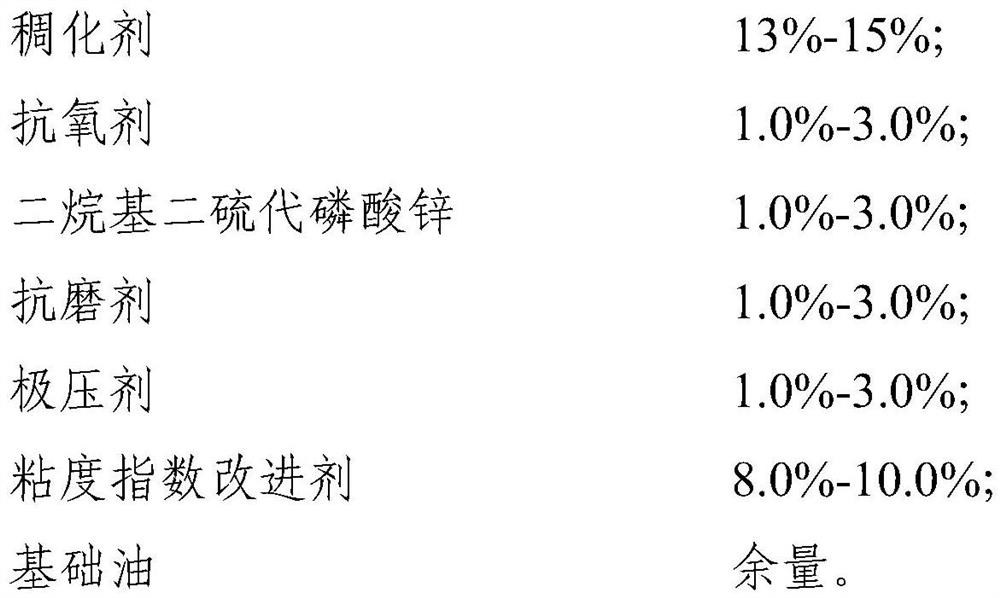

[0041] This embodiment firstly provides a kind of high-power weight cylinder lubricating grease composition, and its formula is:

[0042]

[0043] Wherein, the thickener is prepared from calcium hydroxide, lithium hydroxide, lauryl hydroxystearic acid and sebacic acid; the mass ratio of the calcium hydroxide to the lithium hydroxide is 1:7.69; The mass ratio of the sebacic acid and the lauryl hydroxystearic acid is 1:3. The antioxidant is: GA-034. The antiwear agent is calculated by weight percentage: 1.0% tricresyl phosphate (TCP), 0.5% vulcanized cottonseed oil (T405), 1.0% oil-soluble molybdenum dialkyldithiocarbamate. The extreme pressure agent is aminothioester (T323). The viscosity index improver is JINEX6130 by weight percentage. The base oil is a mixture of 500SN (Mobil), 120BS (Maoming), HVI900 (Maoming) and Mobil PAO65 (metallocene) with a mass ratio of 6:2:1:1.

[0044] The present embodiment further provides a preparation method of the high-power heavy hamme...

Embodiment 2

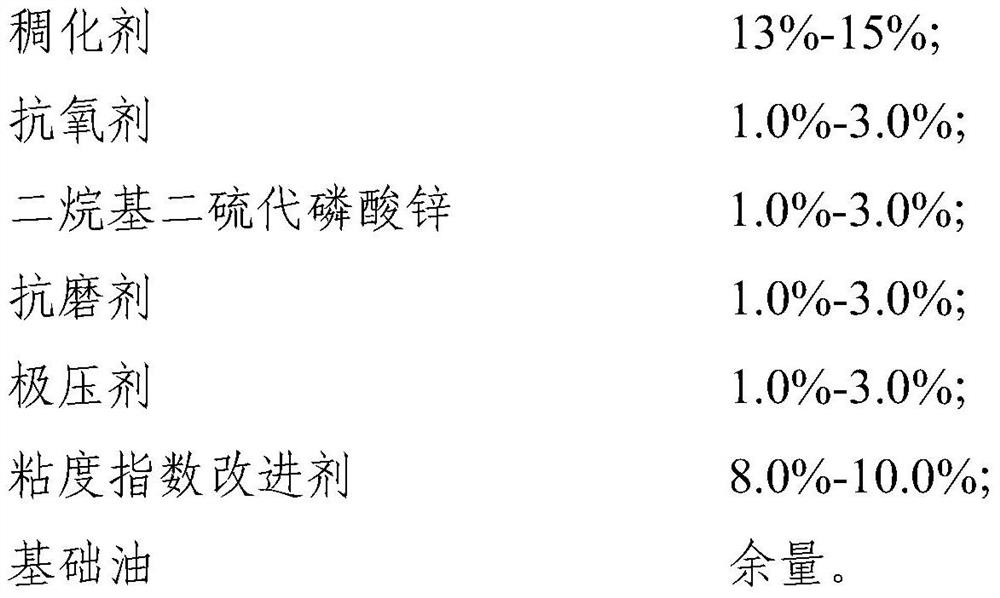

[0047] This embodiment firstly provides a kind of high-power weight cylinder lubricating grease composition, and its formula is:

[0048]

[0049]

[0050] Wherein, the thickener is prepared from calcium hydroxide, lithium hydroxide, lauryl hydroxystearic acid and sebacic acid; the mass ratio of the calcium hydroxide to the lithium hydroxide is 1:7.69; The mass ratio of the sebacic acid and the lauryl hydroxystearic acid is 1:3. The antioxidant is: GA-034. The anti-wear agent is calculated by weight percentage: 1.0% tricresyl phosphate (TCP), 0.5% vulcanized cottonseed oil (T405), 1.5% oil-soluble molybdenum dialkyl dithiocarbamate. The extreme pressure agent is aminothioester (T323). The viscosity index improver is JINEX6130 by weight percentage. The base oil is a mixture of 500SN (Mobil), 120BS (Maoming), HVI900 (Maoming) and Mobil PAO65 (metallocene) with a mass ratio of 6:2:1:1.

[0051] The present embodiment further provides a preparation method of the high-pow...

Embodiment 3

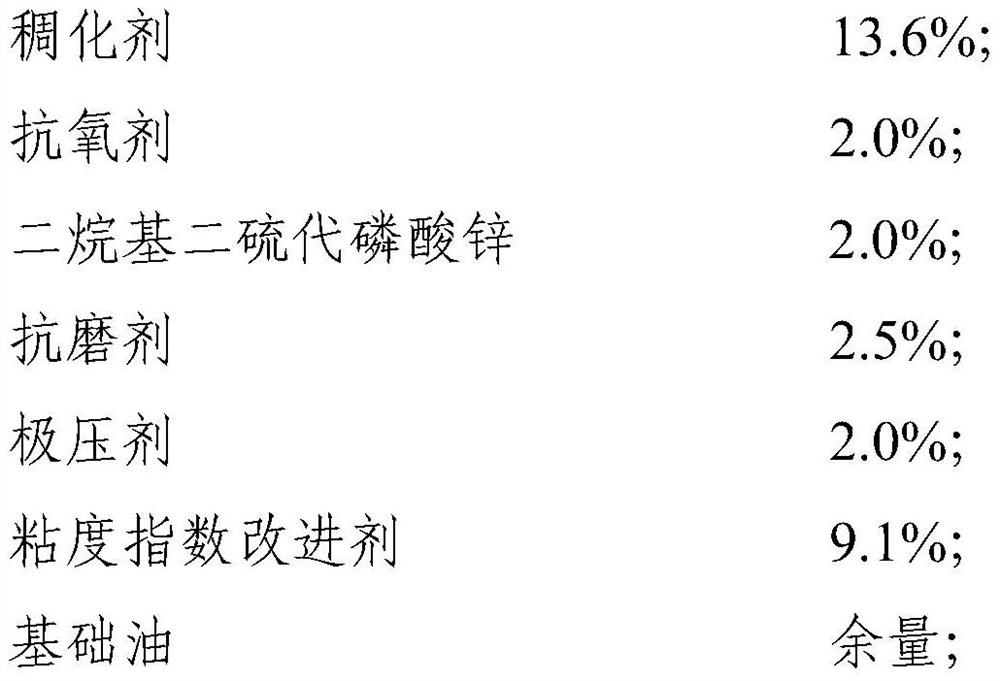

[0054] This embodiment firstly provides a kind of high-power weight cylinder lubricating grease composition, and its formula is:

[0055]

[0056] Wherein, the thickener is prepared from calcium hydroxide, lithium hydroxide, lauryl hydroxystearic acid and sebacic acid; the mass ratio of the calcium hydroxide to the lithium hydroxide is 1:7.69; The mass ratio of the sebacic acid and the lauryl hydroxystearic acid is 1:3. The antioxidant is: GA-034. The anti-wear agent is calculated by weight percentage: 0.25% tricresyl phosphate (TCP), 0.5% vulcanized cottonseed oil (T405), 0.25% oil-soluble molybdenum dialkyl dithiocarbamate. The extreme pressure agent is aminothioester (T323). The viscosity index improver is JINEX6130 by weight percentage. The base oil is a mixture of 500SN (Mobil), 120BS (Maoming), HVI900 (Maoming) and Mobil PAO65 (metallocene) with a mass ratio of 6:2:1:1.

[0057] The present embodiment further provides a preparation method of the high-power heavy h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com