A light-weight high-temperature electrical connector with detachable contacts

A technology for electrical connectors and contacts, applied in contact parts, fixed/insulated contact members, connections, etc., can solve the problems of restriction, heavy weight, lack of maintainability, etc., to meet the reliability and high temperature requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

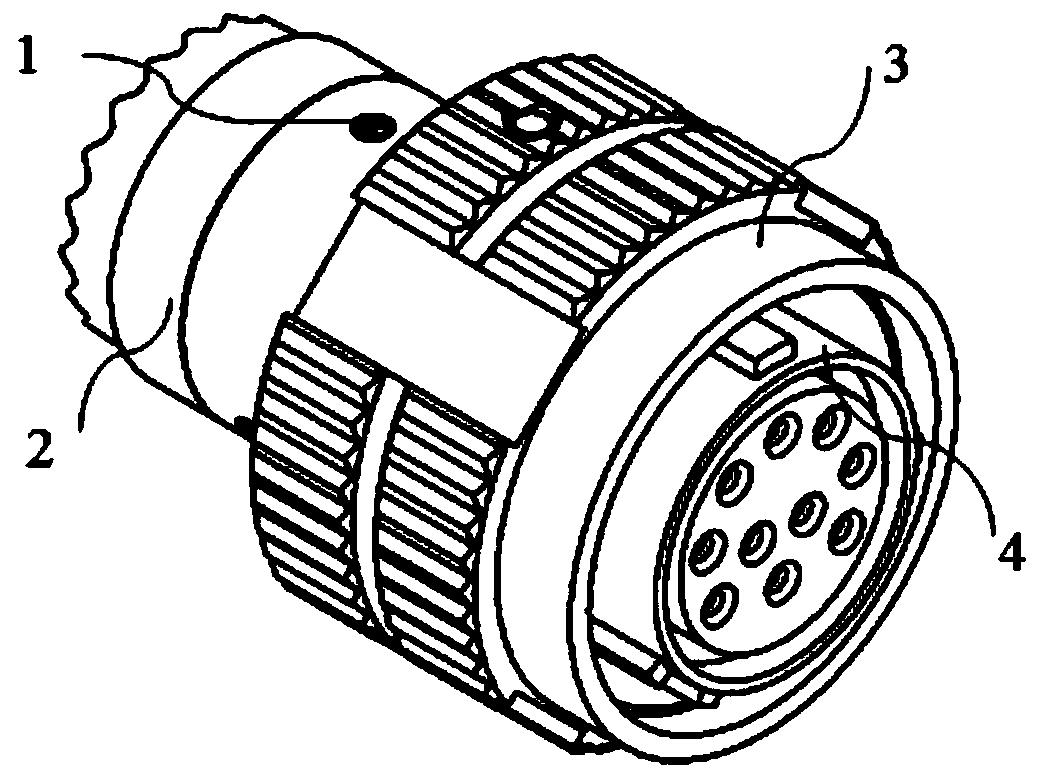

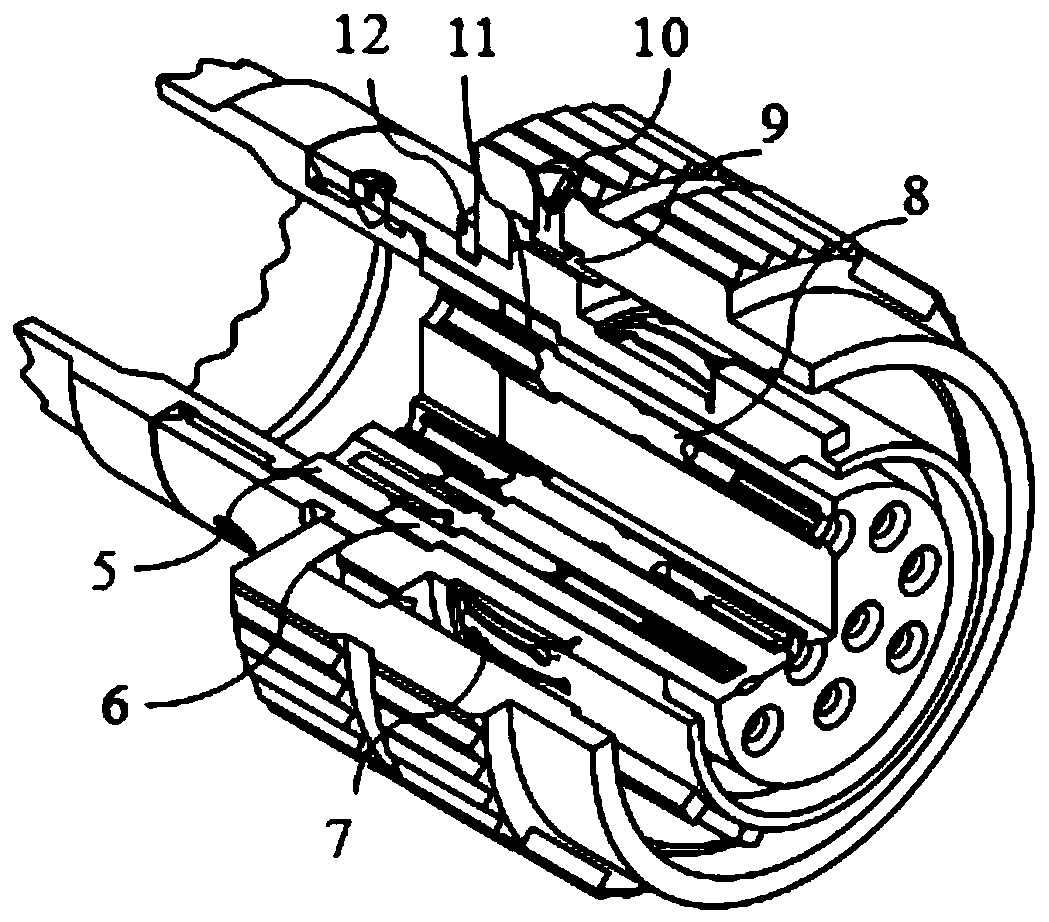

[0033] As mentioned above, when assembling, first install the spring ring 11 into the upper base 6, and then buckle the lower base 5 to the end of the upper base 6 to form a base joint (see image 3 ); Secondly, install the base assembly into the housing 4 as a whole. After the screw nut 2 and the end of the housing 5 are screwed in place, press the base assembly, and then install 3 setscrews 1 around the circumference to prevent the nut 2 from turning It will loosen afterwards; finally, after completion, fasten the shielding reeds on the shell 4 in 7 circles to complete the shell assembly (see Figure 4 )assembly.

[0034] Further, the rivet 10 passes through the holes on the metal locking piece 9 and the screw sleeve 3, and is turned over to fix the metal locking piece 9 on the locking screw sleeve 3 to form a screw fitting (see Figure 5 ), the screw sleeve fitting is installed from the end of the housing fitting and fixed by the retaining ring 12, thus completing the entire co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com