Ultra-low thermal shrinking polyurethane ultrafine fiber base cloth and preparation method thereof

A superfine fiber, polyurethane technology, applied in the direction of fiber type, fiber processing, textile material processing, etc., can solve the problems of not fully meeting the customer's high-temperature processing requirements, damage to the base cloth, and increasing the cost of drying cloth, so as to meet the high-temperature drying requirements. It can meet the requirements of veneer, ultra-low thermal shrinkage, and the effect of meeting the requirements of high temperature use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The non-woven fabric formed by needle punching of nylon 6 and polyethylene as raw materials of sea-island staple fiber is immersed in the wet slurry, then coagulated and washed with water, then the polyethylene is reduced in hot toluene and the wet cloth is oiled. Continuous kneading to obtain ultra-low heat shrinkable polyurethane microfiber base fabric;

[0041] The spinning, non-woven needle punching process, impregnating slurry batching, impregnation, coagulation and water washing process, and weight reduction process are all conventional processes in the field. Reference: Qu Jianbo: Synthetic Leather Technology [M ]. Beijing: Chemical Industry Press. 2015. The processing technology reported in P18-P211.

[0042] Wherein, the oiling process parameters of the wet cloth include:

[0043] The oiling method is padding treatment, three padding and three rolling;

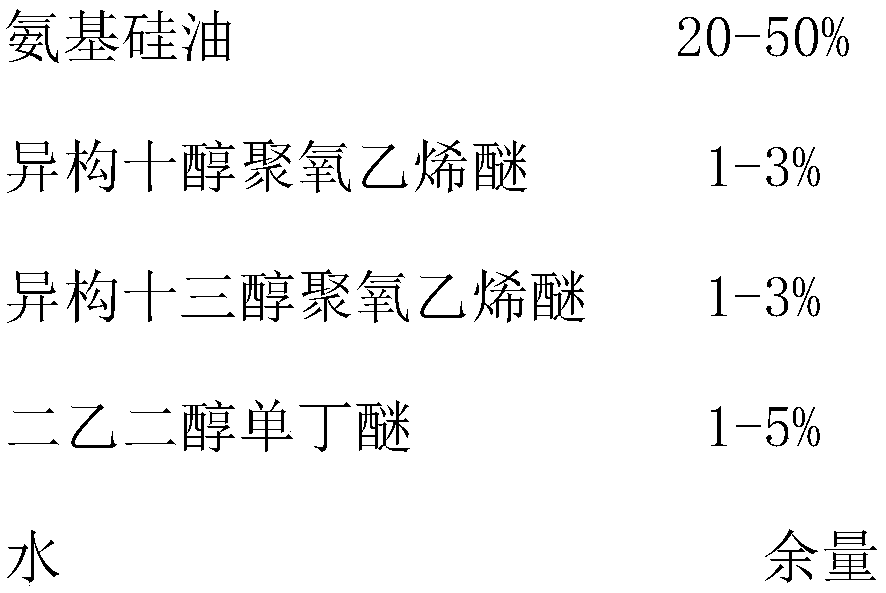

[0044] The upper oil is composed of the following mass percentage components:

[0045]

[0046] The oil concentratio...

Embodiment 2

[0055] The non-woven fabric formed by needle punching of polyester and polyethylene as raw materials of sea-island short fibers is immersed in a wet slurry, then coagulated and washed with water, then the polyethylene is reduced in hot toluene, and the wet cloth is oiled. Continuous kneading to obtain ultra-low heat shrinkable polyurethane microfiber base fabric;

[0056] The spinning, non-woven needle punching process, impregnating slurry batching, impregnation, coagulation and washing process, and weight reduction process are all conventional processes in the field. References: Qu Jianbo: Synthetic Leather Technology [M ]. Beijing: Chemical Industry Press. 2015. The processing technology reported in P18-P211.

[0057] Wherein, the oiling process parameters of the wet cloth include:

[0058] The oiling method is padding treatment, preferably three dip and three rolling;

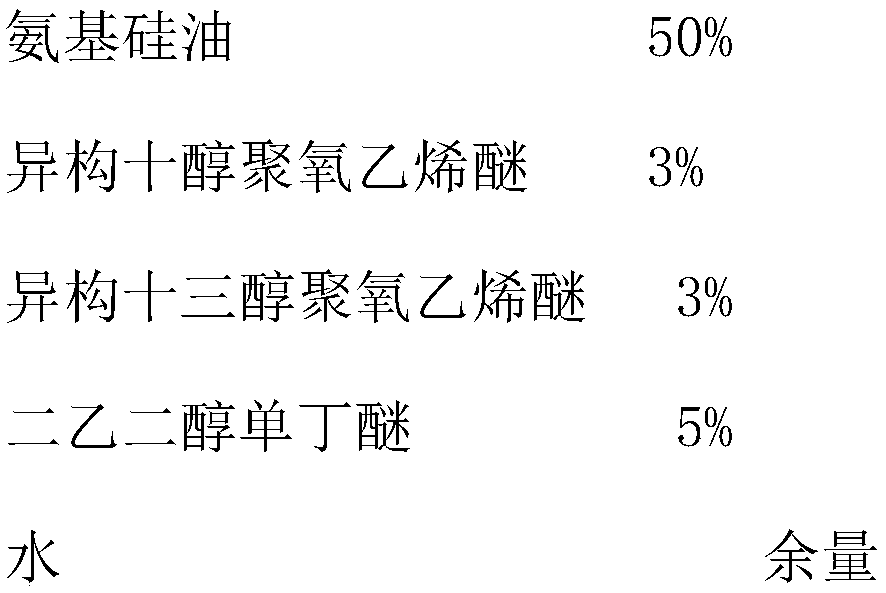

[0059] The upper oil is composed of the following mass percentage components:

[0060]

[0061] The concentration...

Embodiment 3

[0070] The non-woven fabric formed by needle punching of nylon 6 and styrene as raw materials of sea-island staple fiber is immersed in the wet slurry, then coagulated and washed with water, then the polyethylene is reduced in hot toluene, and the wet cloth is oiled. Continuous kneading to obtain ultra-low heat shrinkable polyurethane microfiber base fabric;

[0071] The spinning, non-woven needle punching process, impregnating slurry batching, impregnation, coagulation and water washing process, and weight reduction process are all conventional processes in the field. Reference: Qu Jianbo: Synthetic Leather Technology [M ]. Beijing: Chemical Industry Press. 2015. The processing technology reported in P18-P211.

[0072] Wherein, the oiling process parameters of the wet cloth include:

[0073] The oiling method is padding treatment, preferably three dip and three rolling;

[0074] The upper oil is composed of the following mass percentage components:

[0075]

[0076] The concentration...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com