Patents

Literature

32results about How to "Fine crease" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

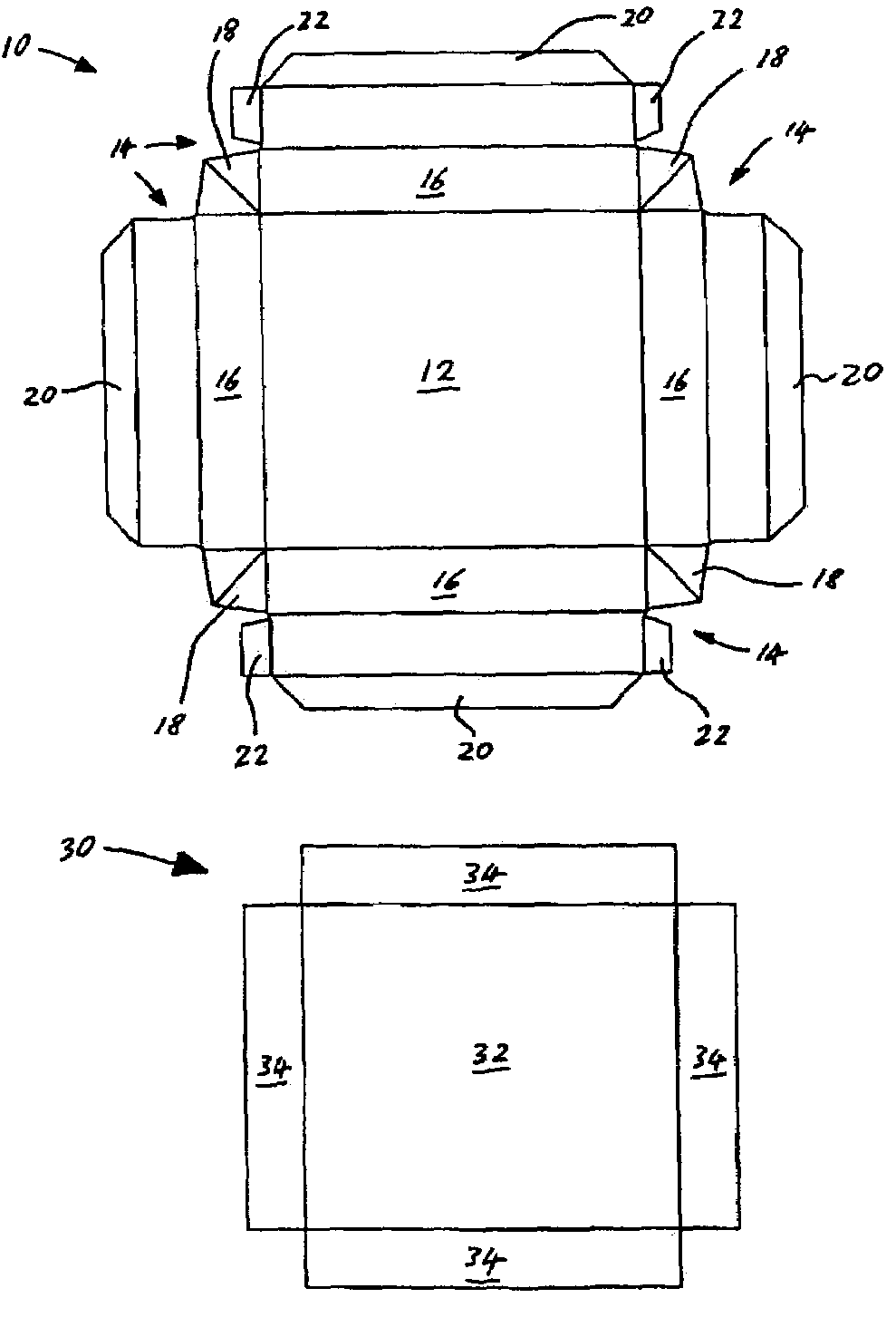

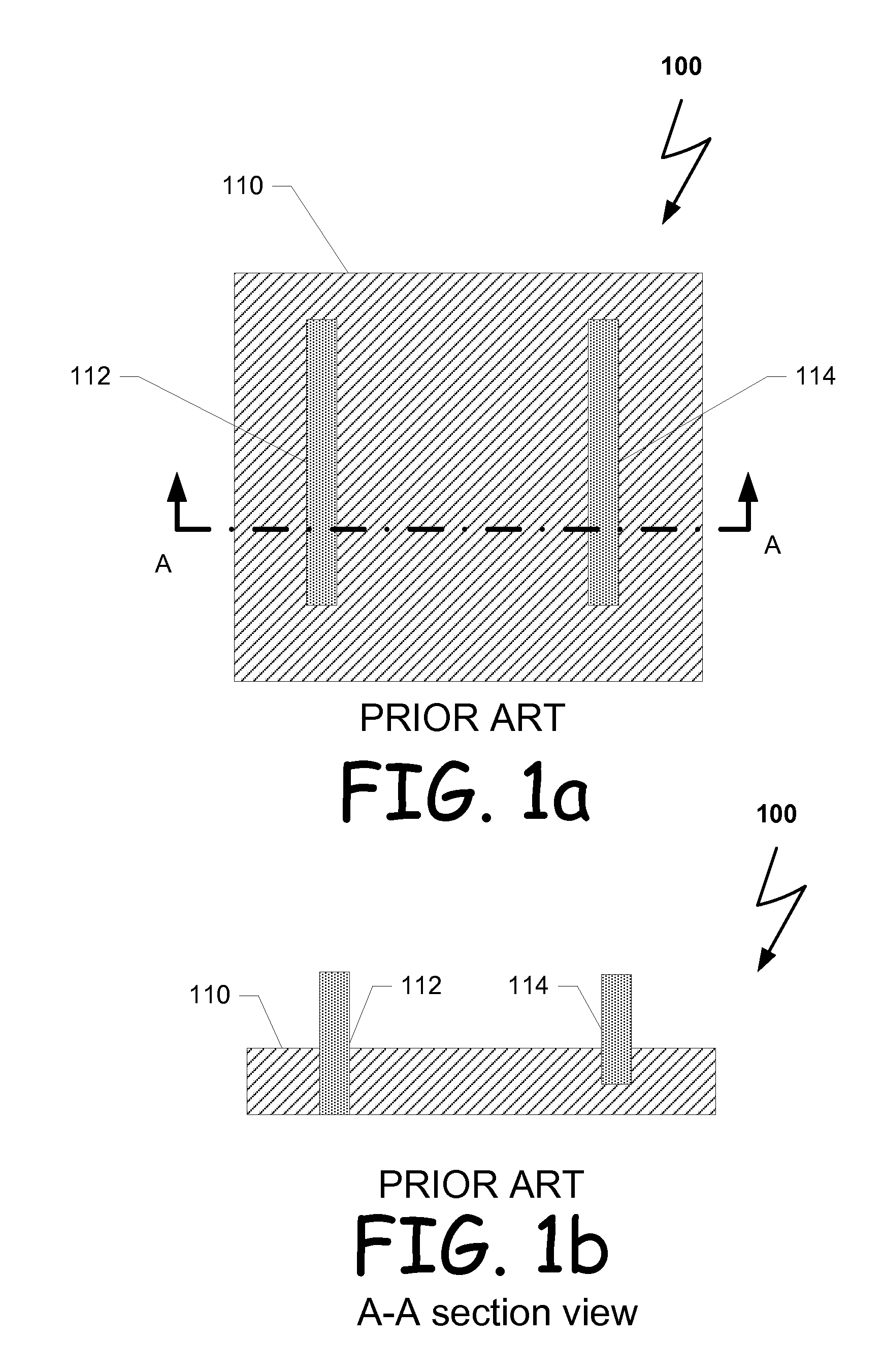

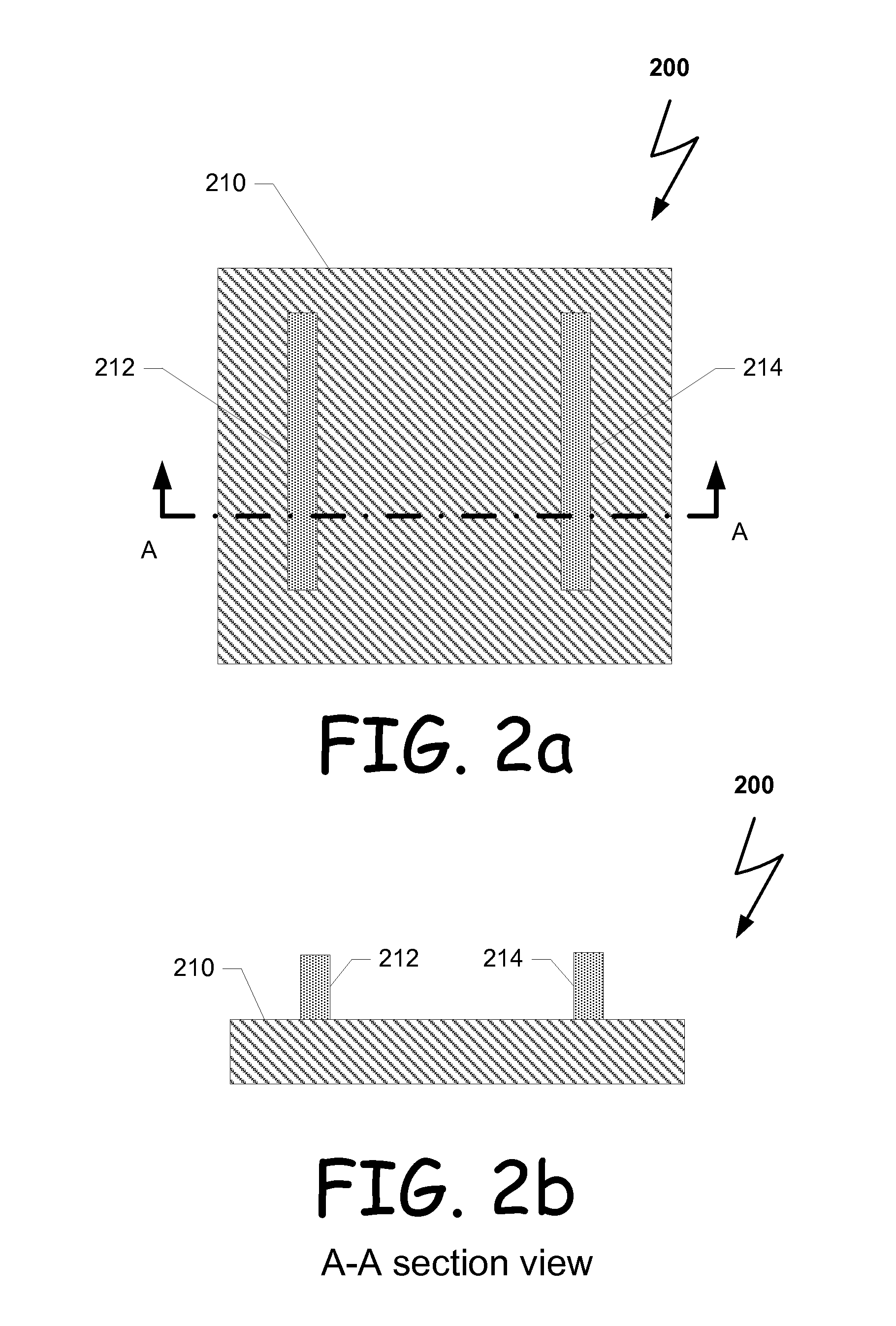

Tray

ActiveUS7044359B1Enhance appearanceLess expensiveBoxes/cartons making machineryRemovable lids/coversEngineeringSurface plate

The invention relates to a cover, an insert and a floor, and a method for manufacturing a tray therefrom. The cover comprises a planar rectangular panel with a flap on each edge, a portion of each flap being connected to an adjacent flap with a gusset, each flap having a tab at the free edge thereof, wherein the floor comprising a planar rectangle which is substantially the same size as the panel, and wherein the insert comprising a planar rectangular base which is substantially the same size as the panel, the base having a wall portion on each edge, each flap being substantially twice the size of each wall portion, wherein in use the base is aligned with the panel, the wall portions are upright, the flaps extend around the respective wall portions and the tabs are folded onto the base, the floor being aligned with the base and the panel, and being bonded to the tabs. A tray so arranged is less expensive and stronger than prior art trays. The cover is not glued to the insert, which reduces manufacturing costs and provides greater versatility in decoration options for the cover.

Owner:KNOLL PRINTING & PACKAGING

Polyurethane resin and preparation method and application thereof

ActiveCN104004159APrevents self-crosslinking reactionsAvoid gel phenomenonFibre treatmentPolyesterPolymer science

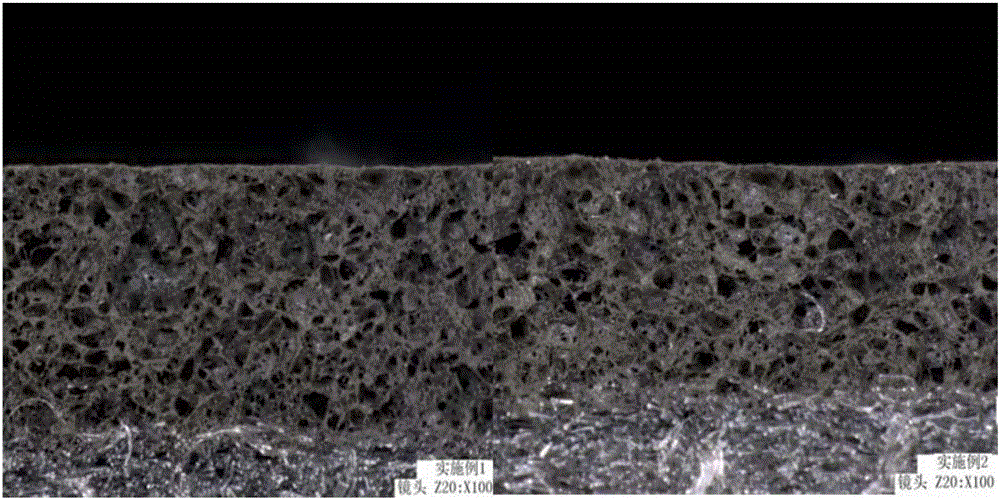

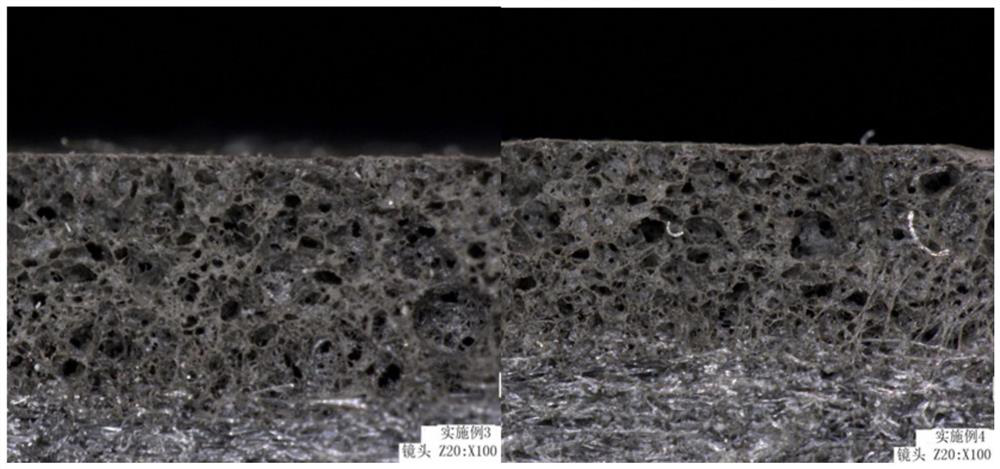

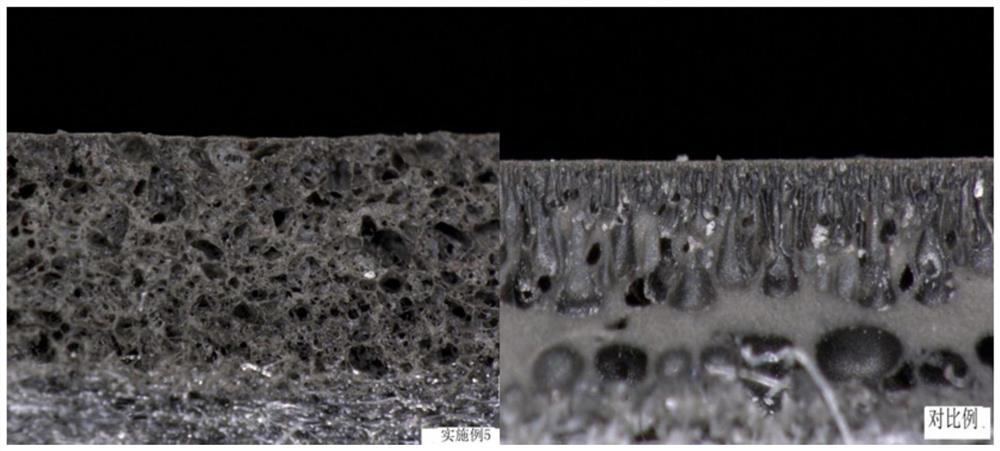

The invention provides polyurethane resin. The polyurethane resin is mainly prepared from, by weight, 150 parts to 200 parts of polyols, 10 parts to 45 parts of chain extender, 100 parts to 150 parts of isocyanate, 0.1 part to 10 parts of antioxidant, 0.1 part to 1 part of reaction terminator, 500 parts to 800 parts of solvent and reaction activity regulator. The polyols contain 40 percent to 70 percent of PTMG, 0 to 45 percent of polyester polyol, 0 to 15 percent of polycarbonate diol, 0 to 25 percent of polycaprolactone diol and 5 percent to 10 percent of modified polydimethylsiloxane diol. The invention further provides a preparation method and application of the polyurethane resin. Tiny and even cells can be formed when the prepared polyurethane resin is used for processing superfine fiber synthetic leather, and thus the produced superfine fiber product can have fine fold lines and plump fleshy feeling.

Owner:XUCHUAN CHEM SUZHOU

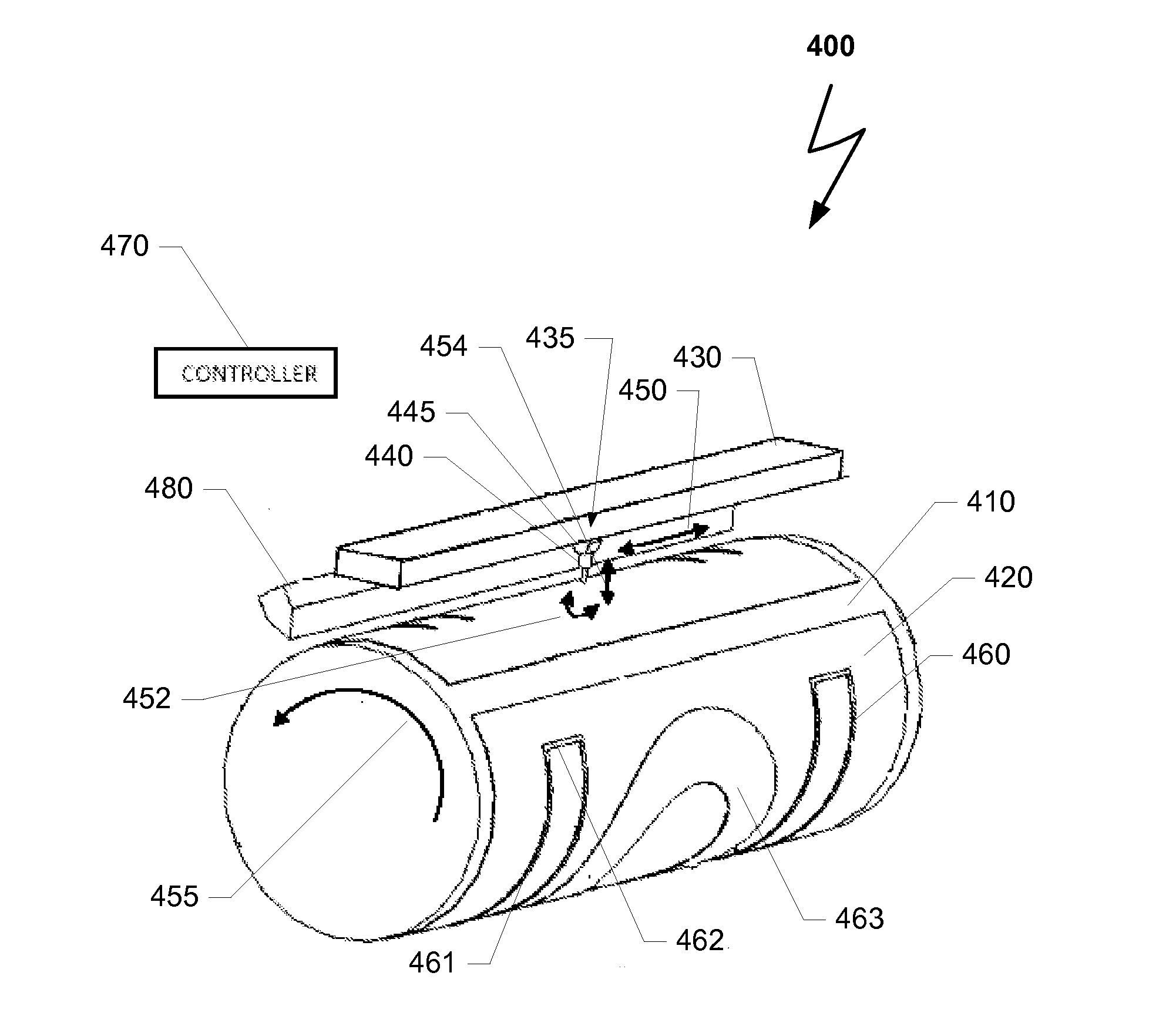

Method and system for surface adhesive rule technology

ActiveUS20120121802A1Quality improvementReduce the numberMechanical working/deformationCoatingsCardboardActuator

A surface-adhesive-rule technology (SART) method and system for creating a surface-adhesive-rule die and counter die for pre-treating cardboard. Wherein the pre-treating comprises: creasing and / or cutting and / or embossing the cardboard. The SART system may comprise: a rule-drawer having one or more cartridges, one or more nozzles, and one or more pressure actuator; a leading mechanism that carries the rule-drawer; and a controller that controls the rule-drawer and the leading mechanism according to a layout of a surface-adhesive-rule die. Each cartridge may comprise flexible materiel and may be associated with one of the nozzles having an orifice with a profile. Further the leading mechanism moves the rule-drawer and the rule-drawer draws a plurality of surface-adhesive rules from the flexible material having an attribute to reserve the shape of the orifice profile through which it is deposited on the surface of a die's body according to commands obtained from the controller.

Owner:HIGHCON SYST

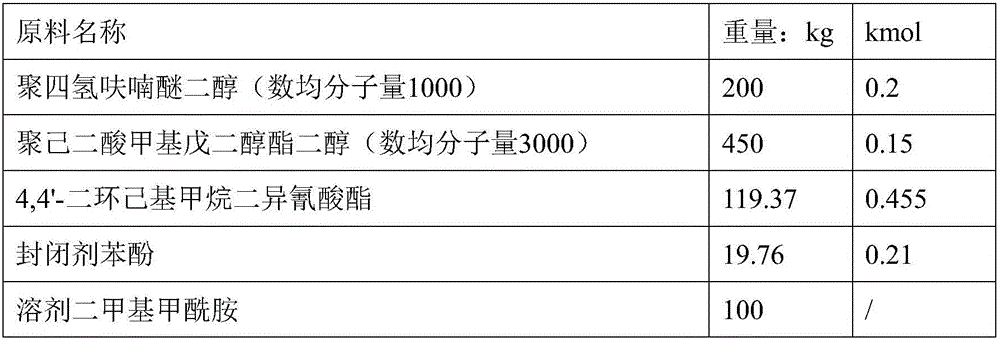

High solid content two-liquid type adhesive layer polyurethane resin and preparation method thereof

InactiveCN106750084AReduce usageReduce negative impactPolyureas/polyurethane adhesivesPolymer scienceSolvent

The invention discloses high solid content two-liquid type adhesive layer polyurethane resin and a preparation method thereof. The high solid content two-liquid type adhesive layer polyurethane resin is prepared from the following raw materials: polyhydric alcohols, diisocyanate, a sealing agent and a solvent, wherein the polyhydric alcohols comprise a polyhydric alcohol A and a polyhydric alcohol B; the polyhydric alcohol A is selected from polyadipic acid ethylene glycol and butanediol copolyester diol, polyadipic acid diglycol ethylene glycol copolyester diol and polytetrahydrofuranether diol or polytetrahydrofuran ethylene oxide copolyether diol; the polyhydric alcohol B is a polyhydric alcohol which contains a side group and is liquid at 20 DEG C. By using part of polyhydric alcohols which are liquid at normal temperature, polyurethane resin with the solid content of 80-90% is obtained, and the use amount of the solvent is reduced; when synthetic leather is prepared, by adding a marketed polyfunctionality compound which can be reacted with a isocyanate group as a crosslinking agent (such as triethylene tetramine) into the resin, smooth kink marks of the synthesized leather can be realized without changing the existing process.

Owner:HUAFON MICROFIBER SHANGHAI

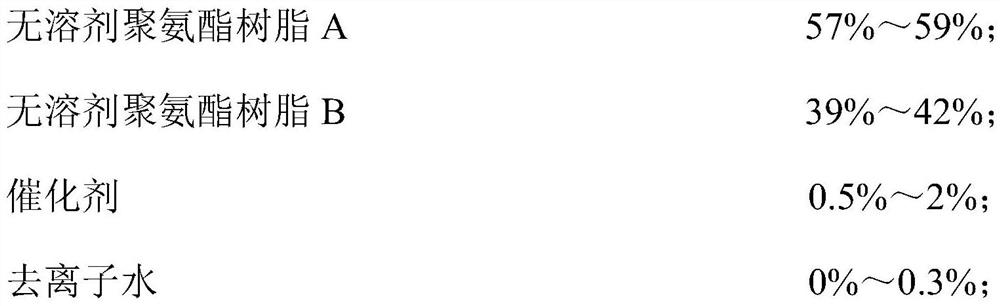

Water-based environment-friendly leather for shoes and preparation method of leather

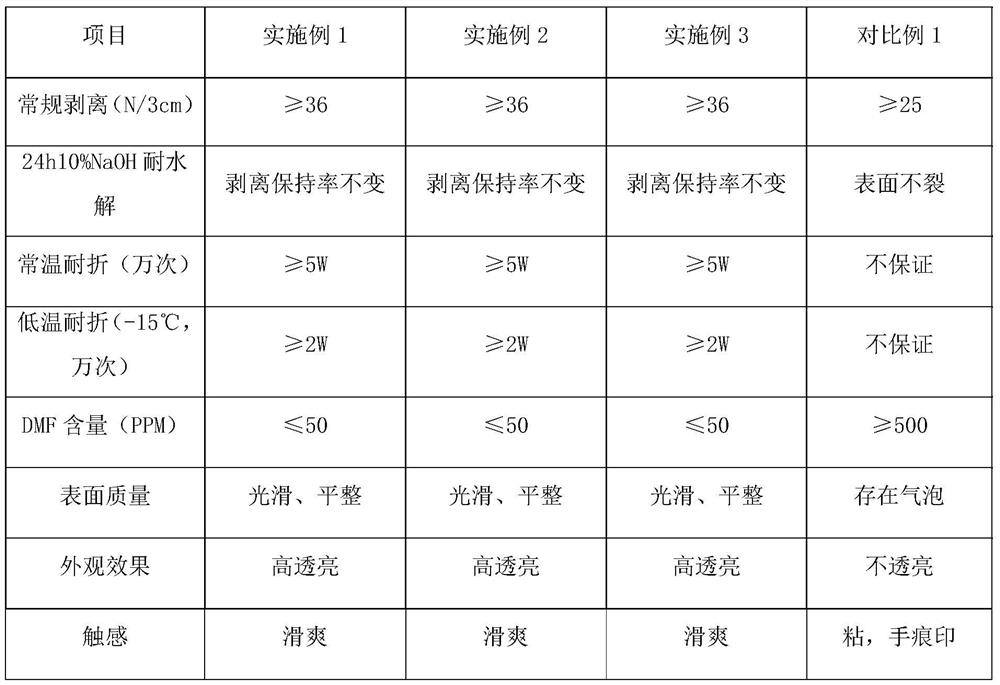

The invention discloses a preparation method of water-based environment-friendly leather for shoes. The preparation method comprises the following steps that A, a surface-layer sizing agent is prepared, and a middle-layer sizing agent is prepared; B, release paper is coated with the prepared surface-layer sizing agent, and after drying and cooling are conducted, a surface layer is formed; C, the surface layer is coated with the prepared middle-layer sizing agent, and after drying and cooling are conducted, a middle layer is formed; D, a foaming-layer sizing agent is uniformly mixed on line through a pouring machine (A / B metering and discharging), coats the middle layer and is pre-dried into a semi-dry state; E, then the foaming-layer sizing agent fits base cloth, drying, cross-linking curing and ripening are conducted, finally the release paper is stripped, and the water-based environment-friendly leather for the shoes is obtained. The preparation method is simple in production process, low in production cost, friendly to the environment and beneficial for the physical health of workers; folded wrinkles on the surface of the prepared water-based environment-friendly leather for theshoes are fine, and the leather has high wear resistance; the finished product has few DMF residues and is friendly to the environment and healthy; the leather has good physical performance and usingperformance.

Owner:ZHEJIANG HEXIN NEW MATERIAL CO LTD

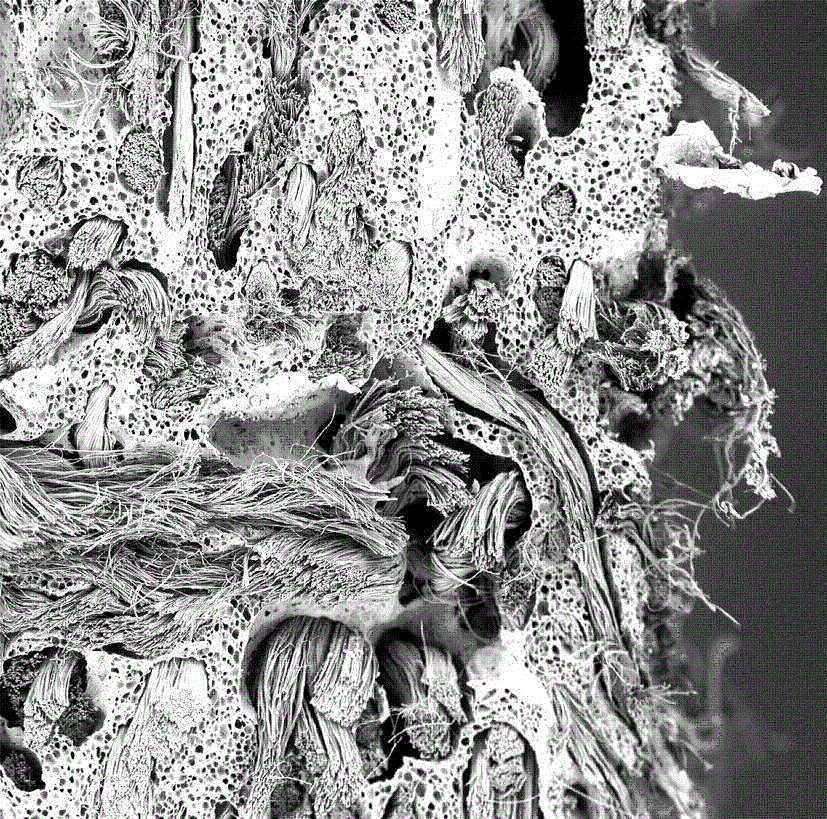

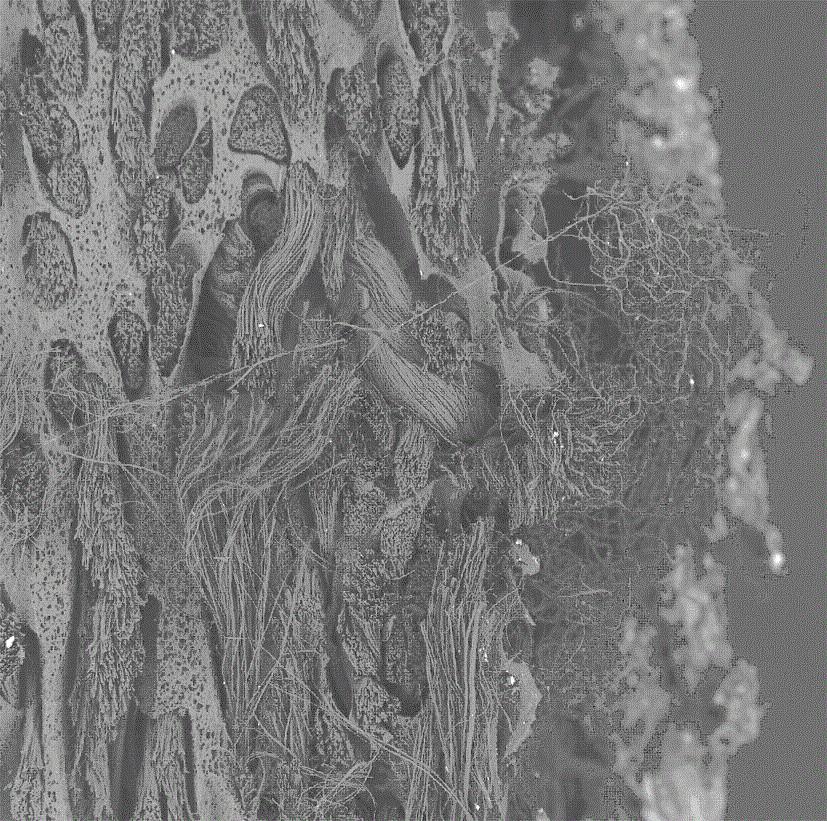

High-simulation superfine fiber nylon-polyurethane base cloth and preparation method thereof

InactiveCN104562437AThick fleshyFine creaseConjugated synthetic polymer artificial filamentsNon-woven fabricsPolymer scienceNylon 6

The invention discloses a piece of high-simulation superfine fiber nylon-polyurethane base cloth and a preparation method thereof. The high-simulation superfine fiber nylon-polyurethane base cloth is prepared from sea-island fiber formed by composite cospinning of nylon 6 and high pressure polyethylene, and a non-woven fabric prepared by a needling method, wherein the weight ratio of nylon 6 to high pressure polyethylene is (35-45): (65-55). The product obtained by the preparation method disclosed by the invention is thick in fleshy feeling, fine and smooth in fold lines and high soft in hand feeling, and is close to the texture of cowhide, so that the product can be widely applied to the field of substituting the cowhide.

Owner:HUAFON MICROFIBER SHANGHAI

Imitation sheepskin ultrafine fiber polyurethane synthetic leather and manufacturing method thereof

ActiveCN103451959AGood flexibilityStrong skin feelingLamination ancillary operationsSynthetic resin layered productsFiberSurface layer

The invention discloses imitation sheepskin ultrafine fiber polyurethane synthetic leather and a manufacturing method thereof. The manufacturing method comprises the following steps: (1) applying oil to raw base cloth A and drying to obtain base cloth B; (2) bonding a sizing agent of surface layer dry-method polyurethane resin to the base cloth B obtained in the step (2) through a polyurethane bonder by a release paper dry-method film-shifting and surface-making technology, and stripping release paper to obtain the imitation sheepskin ultrafine fiber polyurethane synthetic leather. According to the method, the moderately soft base cloth is selected, the base cloth subjected to oil application is high in softness and leather feel, and the surface-overlaid ultrafine fiber polyurethane synthetic leather obtained through a dry-method surface-making process is good in fold lines and smooth feel. The imitation sheepskin ultrafine fiber polyurethane synthetic leather provided by the invention is exquisite in fold lines and smooth in hand feel, has a very good genuine leather feel and successfully solves the problem that exquisite fold lines and high softness of conventional imitation genuine leather ultrafine fiber synthetic leather cannot be compatible.

Owner:HUAFON MICROFIBER SHANGHAI

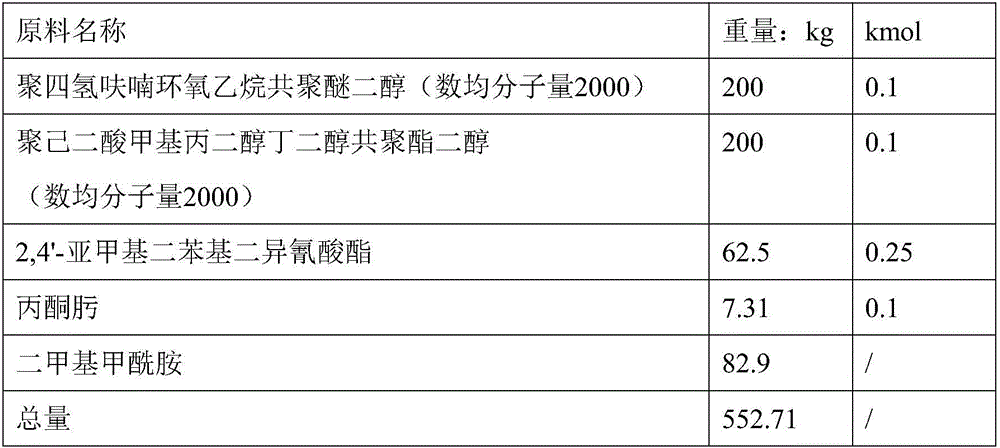

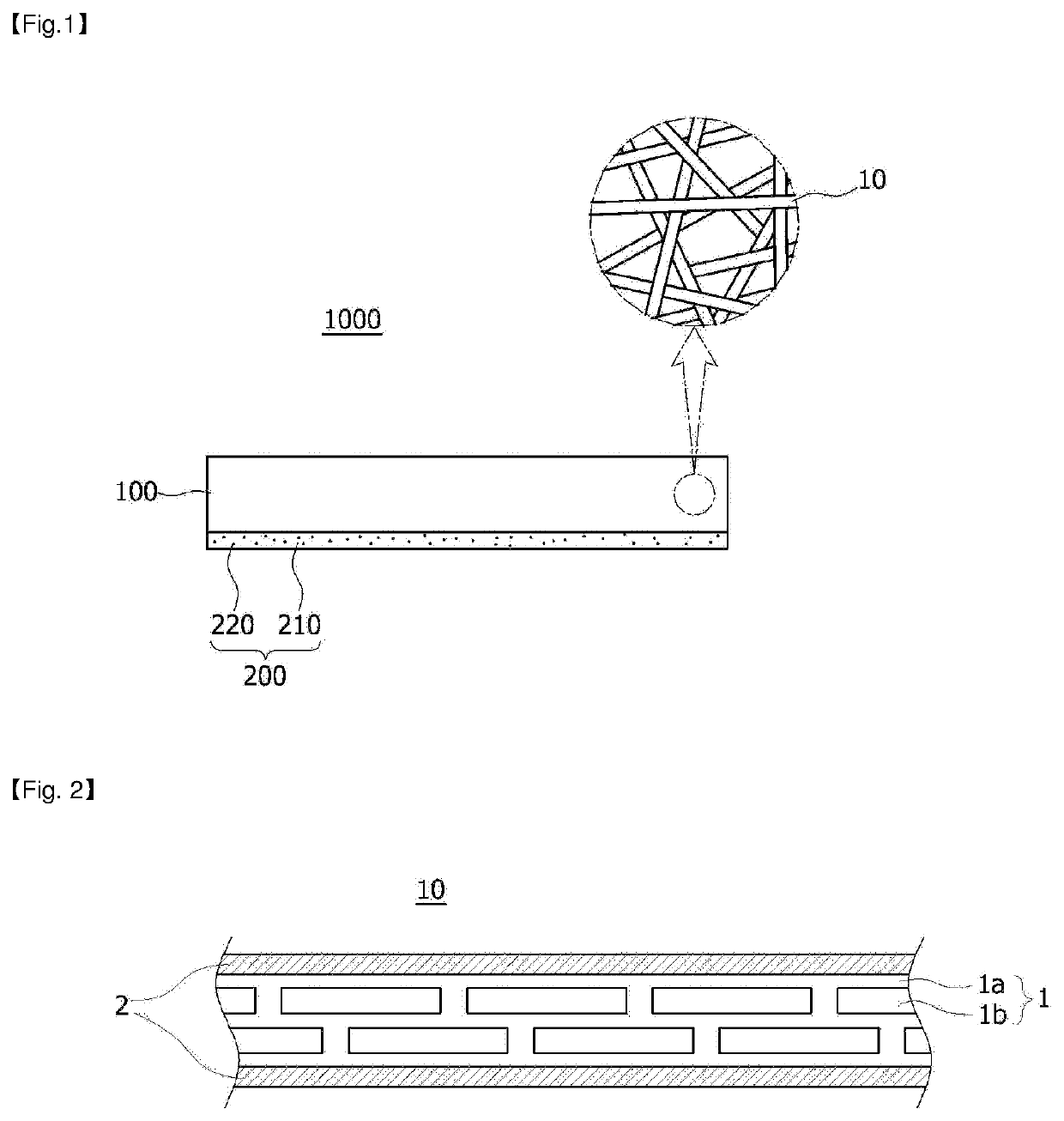

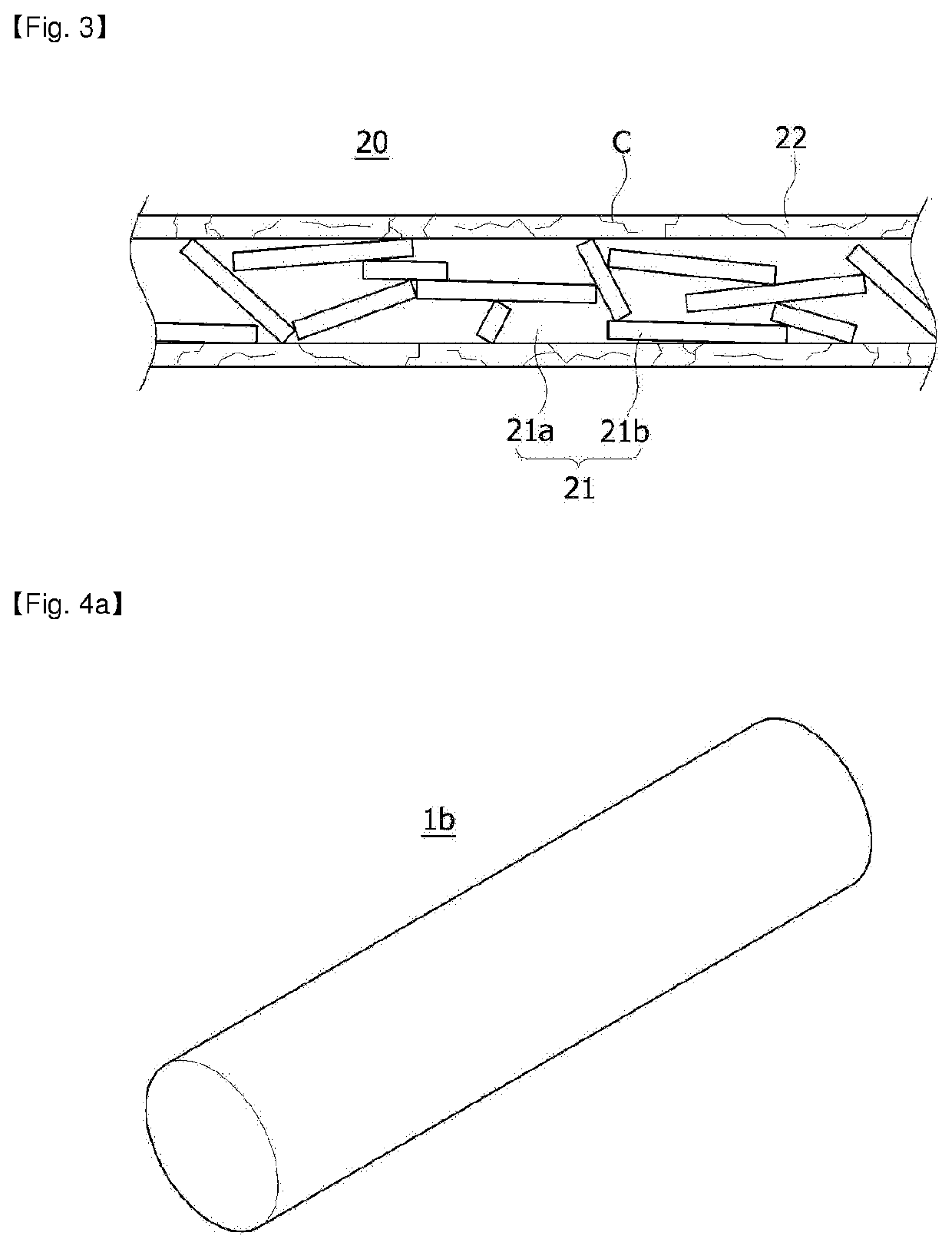

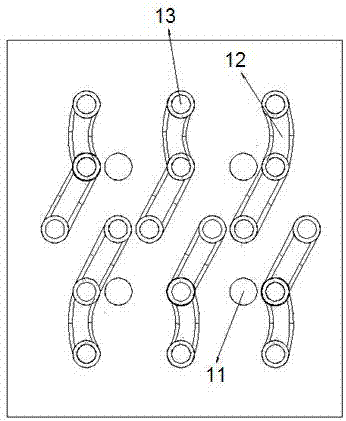

Flexible electromagnetic wave shielding material, electromagnetic wave shielding type circuit module comprising same and electronic device furnished with same

ActiveUS20200100403A1Increase flexibilityIncrease elasticityElectroconductive/antistatic filament manufactureShielding materialsFiberHigh density

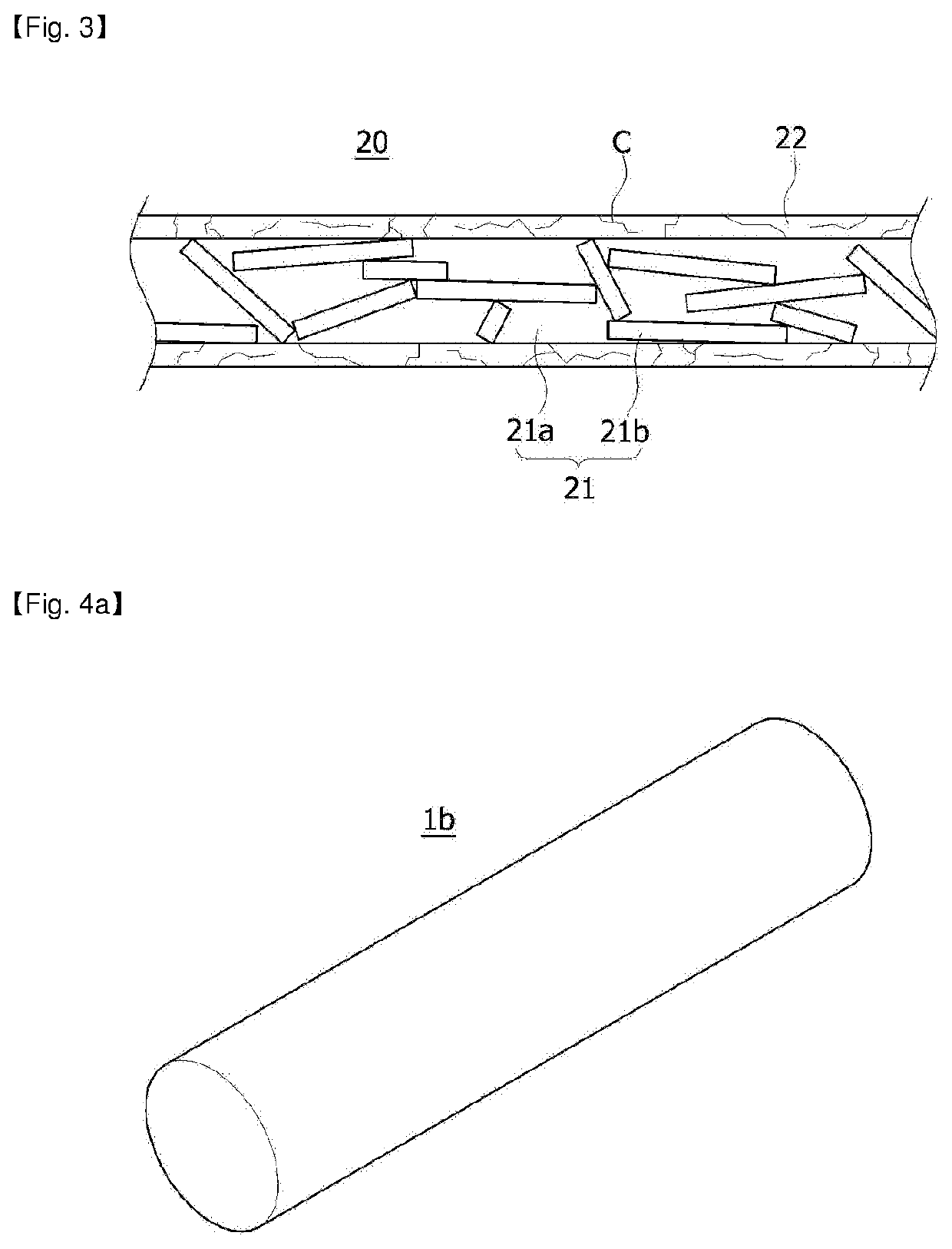

Provided is a flexible electromagnetic wave shielding material. An electromagnetic wave shielding material according to an embodiment of the present invention is implemented to include a conductive fiber web including a conductive composite fiber including a metal shell part covering an outside of a fiber part such that the conductive composite fiber forms multiple pores; and a first conductive component provided in at least some of the pores. The electromagnetic wave shielding material is so excellent in flexibility, elasticity, and creasing / recovery that the electromagnetic wave shielding material may be freely changed in shape, and can be brought in complete contact with a surface where the electromagnetic wave shielding material is intended to be disposed even if the surface has a curved shape such as an uneven portion or a stepped portion, thus exhibiting excellent electromagnetic wave shielding performance. Also, it is possible to prevent deterioration of the electromagnetic wave shielding performance even with various shape changes. Furthermore, even if parts are provided in a narrow area at a high density, the electromagnetic wave shielding material can be brought into complete contact with the mounted parts by overcoming a tight space between the parts and a stepped portion. Thus, the present invention can be easily employed for a light, thin, short, and small or flexible electronic device.

Owner:AMOGREENTECH CO LTD

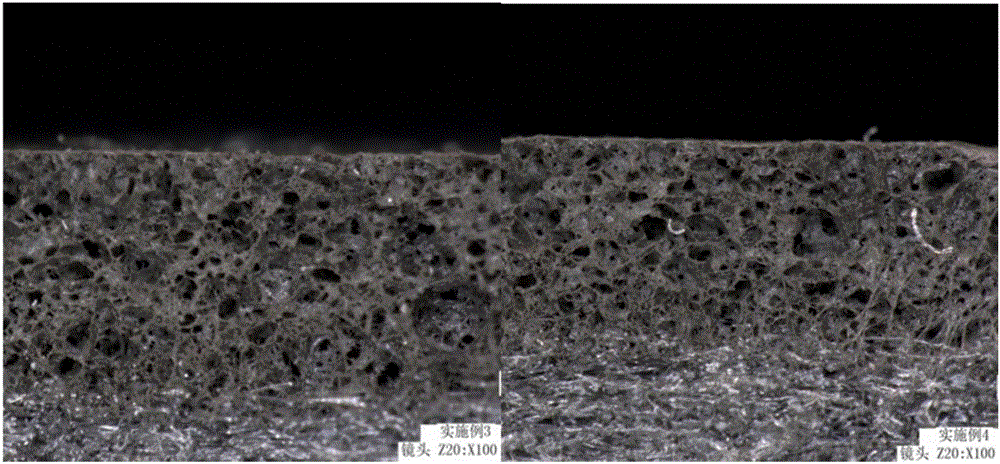

Preparation method of high-cotton-feeling micro-fiber sofa leather base

ActiveCN109537291AVoluptuousFine creaseFibre typesConjugated synthetic polymer artificial filamentsNonwoven fabricRubbing

The invention belongs to the technical field of preparation of superfine fiber synthetic leather, and particularly relates to a preparation method of a micro-fiber sofa leather base. The preparation method of the micro-fiber sofa leather base comprises the following treatment steps: spinning, making of a non-woven fabric, shaping of the non-woven fabric, wet-process impregnation, extraction, drying and oiling, leather rubbing and aftertreatment. In the preparation method of the invention, novel polyurethane is used for carrying out wet-process impregnation on a micro-fiber nonwoven fabric, incooperation with a reasonable micro-fiber production process, the prepared micro-fiber base has the characteristics of plumpness, fine and smooth folding marks and the like, the grade of the micro-fiber sofa leather can be improved, the micro-fiber sofa leather can rival buttermilk skin and goat skin, consumption of raw materials is greatly reduced, the recycling value of waste polyethylene is increased, the quality of the product is increased, and the economy is high.

Owner:重庆双象超纤材料有限公司

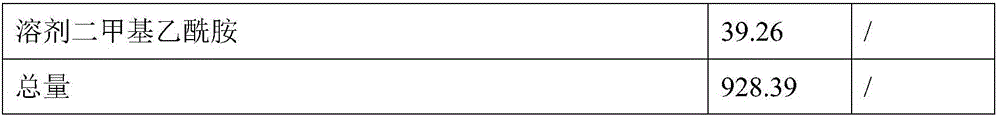

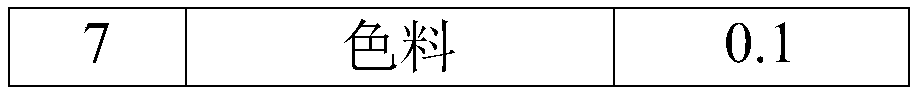

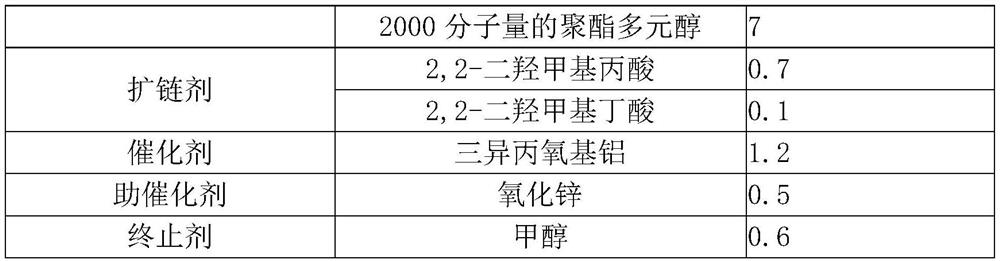

Preparation method of wet-method polyurethane resin for high-cotton-feeling microfiber sofa leather

The invention belongs to the technical field of preparation of polyurethane resin, and particularly relates to a preparation method of wet-method polyurethane resin for high-cotton-feeling microfibersofa leather. The preparation method of the invention comprises the following steps: adding solvent, polyether glycol, polyester glycol, heat-resistant oxidant, and chain extender into a reaction kettle, uniformly stirring, adding 4-diisocyanate, heating to 70 to 90 DEG C, reacting for 60 to 120 minutes, adding the solvent and chain extender, continuously supplementing diisocyanate I to improve the viscosity, adding an aid and solvent after the viscosity meets the requirement, and cooling and discharging to obtain the finished product polyurethane resin. By adopting a special resin synthetic process formula and matching a reasonable microfiber production process, the polyurethane resin prepared by the invention has the characteristics of low solution ratio, high myogenic properties, fullness, fine and smooth crease and the like, can enhance the grade of the microfiber sofa leather and can be comparable to calf leather and goat leather.

Owner:WUXI DOUBLE ELEPHANT MICRO FIBER MATERIAL

Solvent-free top layer leather-imitated microfiber leather processing method

The invention discloses a solvent-free top layer leather-imitated microfiber leather processing method. The method comprises the following steps: 1) a figured or unfigured sea-island fiber composite fiber is used for producing high-density non-woven fabric; 2) a dense layer on the nonwoven fabric is formed by using solvent-free paste to obtain a base fabric, 3) the base fabric impregnated polyurethane slurry is solidified to obtain a synthetic leather semi-finished product, 4) according to different components in sea ingredients in the sea-island fiber, the synthetic leather prepared in the step 3) employs a toluene extraction or alkali decrement technology, sea ingredients in the sea-island fiber is stripped out, and steps of washing and drying are carried out to obtain the solvent-free top layer leather-imitated microfiber leather. The solvent-free top layer leather-imitated microfiber leather has the advantages of soft handle, good drapability, fine folding grain and good physical properties, the simulated effect is better, and no solvent residue is left in the microfiber.

Owner:SHANDONG TONGDA ISLAND NEW MATERIALS

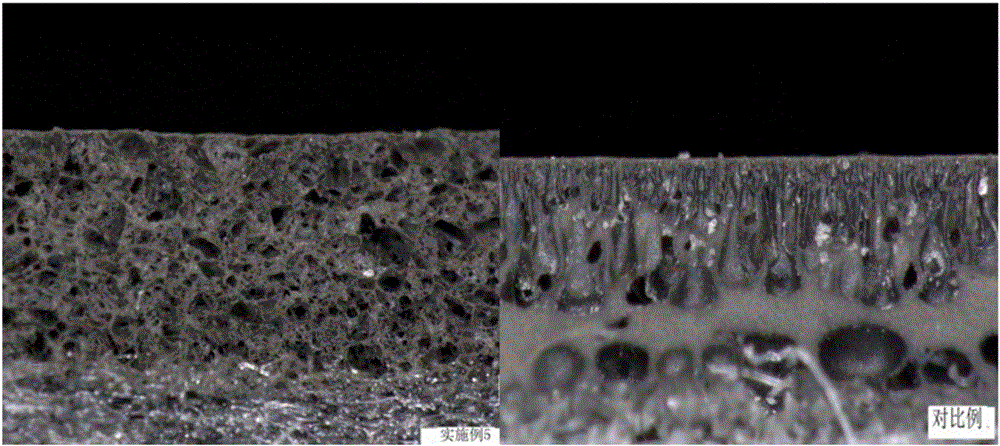

Ultra-soft protein-like wet-process resin, and preparation method and application thereof

ActiveCN106479095AStrong sense of spongeFine creasePolyurea/polyurethane coatingsTextiles and paperDiphenylmethanePolyester

The invention relates to an ultra-soft protein wet resin which is prepared from 5%-10% of polyester / polyether glycol, 0.3%-0.7% of double-hydroxyl-terminated polyether modified silicone oil, 0.3%-1% of ethylene glycol, 2%-5% of diphenylmethane-4,4'-diisocyanate, 15%-20% of polyvinyl alcohol powder, 0.15%-0.25% of polyamide wax and 68%-73% of N,N-dimethylformamide. The present invention also discloses a preparation method of the ultra-soft protein-like wet-process resin. A wet-process leather base prepared from the polyurethane polyvinyl alcohol blend wet-process resin according to the formulation and synthesis process has a strong sense of sponge, honeycombed cell structure like dermal protein fiber and fine crease, and has the characteristics, like dermal protein fiber, of softness, comfort, relaxation and warmness.

Owner:SHANGHAI HUIDE TECH CO LTD

A kind of polyurethane resin and its preparation method and application

ActiveCN104004159BPrevents self-crosslinking reactionsAvoid gel phenomenonFibre treatmentPolyesterPolymer science

The invention provides a polyurethane resin. The raw materials for preparing the polyurethane resin mainly consist of the following components in parts by weight: polyol: 150-200 parts; chain extender: 10-45 parts; isocyanate: 100-150 parts; Oxygen agent: 0.1-10 parts; Reaction terminator: 0.1-1 part; Solvent: 500-800 parts; Reactivity modifier; The content of each component of the polyol: polytetrahydrofuran ether glycol: 40- 70%; Polyester polyol: 0-45%; Polycarbonate diol: 0-15%; Polycaprolactone diol: 0-25%; Modified dimethicone diol : 5-10%. The invention also provides the preparation method and application of the resin. The polyurethane resin prepared by the invention can form small and uniform cells when processing the superfine fiber synthetic leather, so that the produced superfiber can have finer creases and full fleshy feeling.

Owner:XUCHUAN CHEM SUZHOU

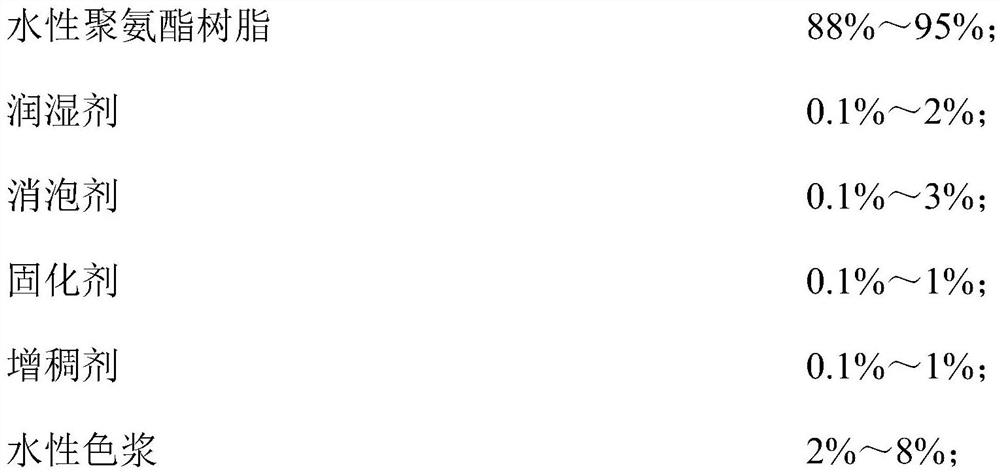

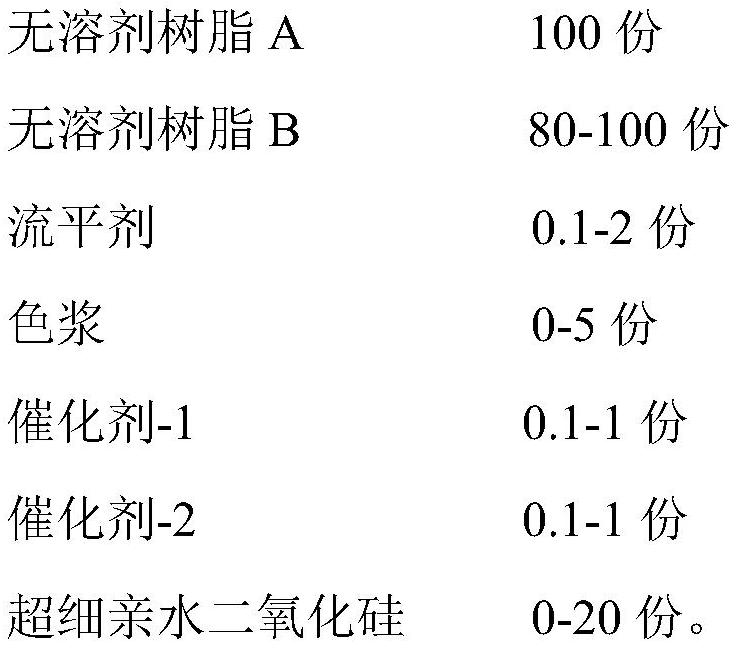

Environment-friendly space leather and preparation method and application thereof

PendingCN112761001AAvoid crackingImprove machinabilityFootwearTextiles and paperPolymer scienceSolvent free

The invention provides environment-friendly space leather and a preparation method and application thereof. The environment-friendly space leather sequentially comprises a waterborne polyurethane resin surface layer, a solvent-free polyurethane resin foaming layer and a waterborne polyurethane resin impregnation layer from top to bottom. The preparation method comprises the following steps that solvent-free polyurethane resin foaming layer slurry is coated on the waterborne polyurethane resin surface layer, drying is carried out to be half-dry, then the waterborne polyurethane resin impregnation layer is laminated, and drying is carried out to obtain the environment-friendly space leather. The environment-friendly space leather prepared by combining the waterborne polyurethane resin and the solvent-free polyurethane resin has high tear strength and high peel strength, is high in genuine leather feeling, full in hand feeling, fine in crease, good in folding fastness, good in wear resistance and good in hydrolysis resistance, and can be used for manufacturing high-end and environment-friendly sports shoe products.

Owner:SHANGHAI HUIDE TECH CO LTD

Preparation method of synthetic leather and synthetic leather

PendingCN114575168ALow densityIncrease softnessTextile/flexible product manufactureTextiles and paperPolymer scienceSpinning

The invention discloses synthetic leather and a preparation method thereof.The preparation method comprises the following steps that PA slices and PE slices are mixed according to a set proportion, and chinlon blended sea-island fibers are prepared through a spinning technology; the chinlon blended sea-island fibers are subjected to a needling process, and 400-460 g / m < 2 > superfine fiber non-woven fabric is obtained; the superfine fiber non-woven fabric is subjected to gradient heat setting through a five-stage drying oven, and base cloth is obtained; impregnating base cloth with polyurethane resin slurry, and then solidifying and washing to obtain an unsplit semi-finished product with the polyurethane content of 15-25wt%; splitting the unsplit semi-finished product by using a benzene decrement method to obtain a split semi-finished product; drying the split semi-finished product, oiling and shaping to obtain a synthetic leather semi-finished product; the synthetic leather semi-finished product is subjected to a dry veneering process to obtain the synthetic leather. The synthetic leather is low in density, good in softness and high in integrity.

Owner:ANTA CHINA

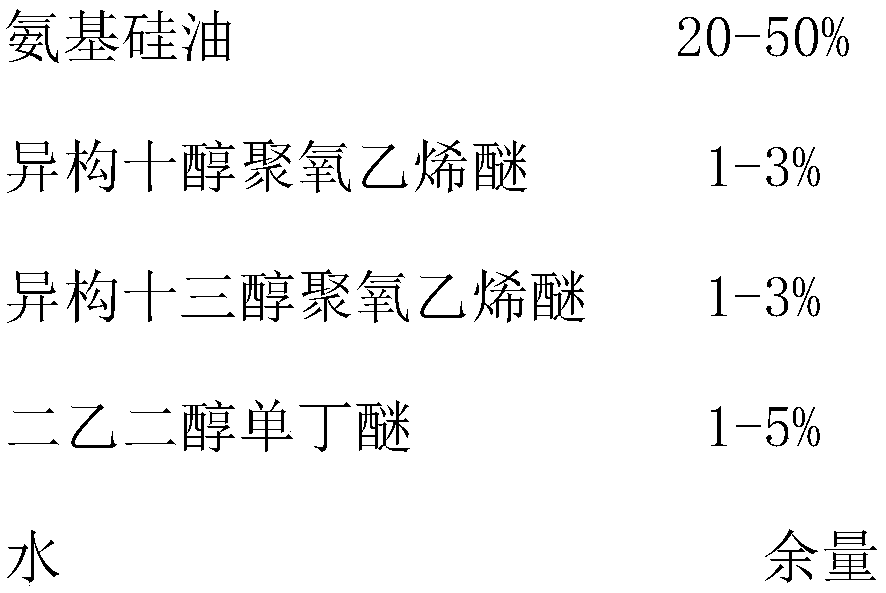

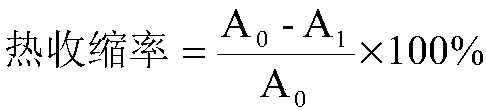

Ultra-low thermal shrinking polyurethane ultrafine fiber base cloth and preparation method thereof

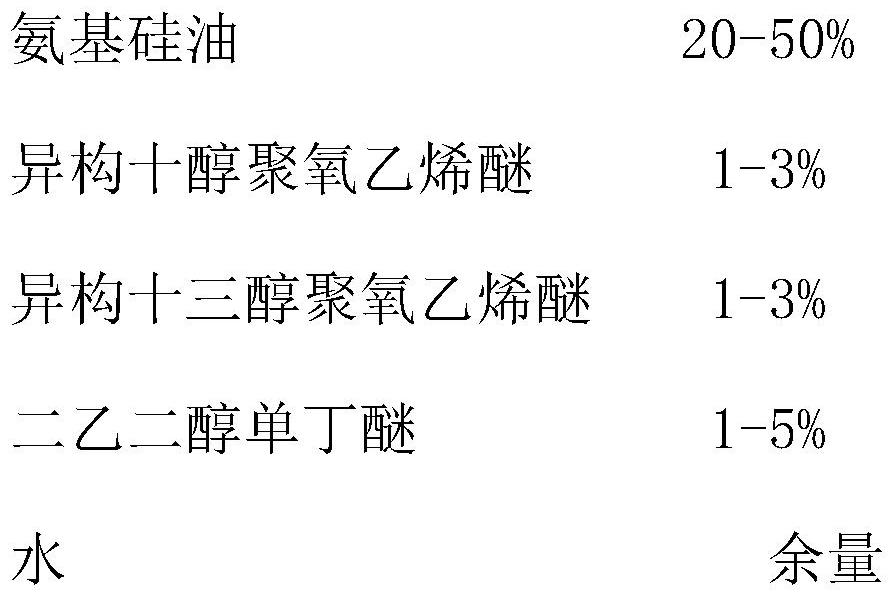

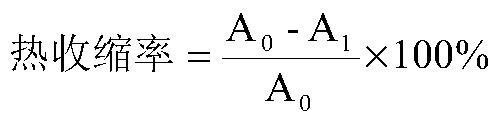

ActiveCN109518467AUltra-low heat shrinkageMeet veneer requirementsPattern makingFibre typesPolyesterFiber

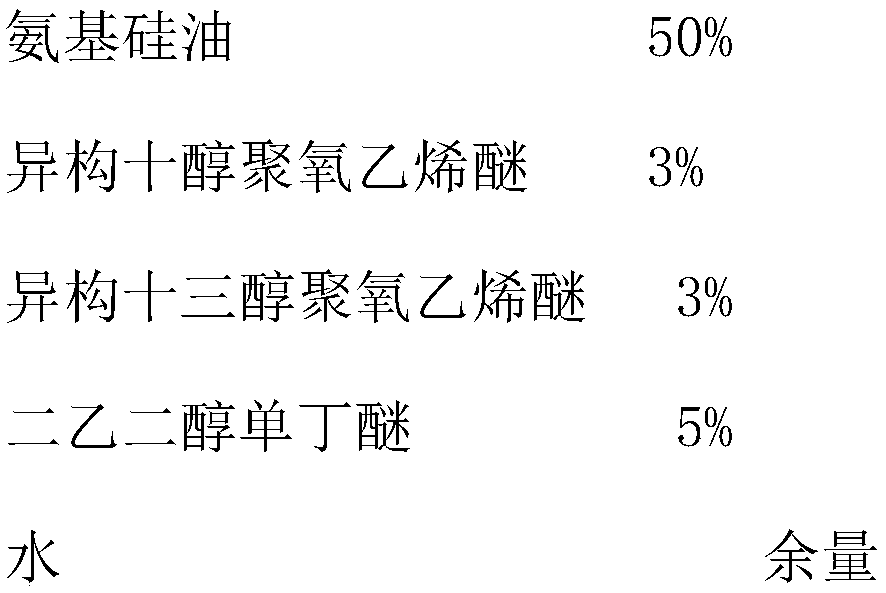

The invention discloses ultra-low thermal shrinking polyurethane ultrafine fiber base cloth and a preparation method thereof. The preparation method of the ultra-low thermal shrinking polyurethane ultrafine fiber base cloth comprises the following steps: impregnating a non-woven fabric formed by needling nylon 6 or polyester and island short fibers prepared from polyethylene or styrene in wet process slurry; then carrying out condensation and washing; extracting polyethylene or styrene in hot methylbenzene to obtain wet cloth; then impregnating the wet cloth in an oiling solution to knead grains continuously and dry to obtain the ultra-low thermal shrinking polyurethane ultrafine fiber base cloth. The oiling solution contains amino silicone oil, isodecanol polyoxyethylene ether, iso-tridecanol polyoxyethylene ether, butyl diglycol acetate and water. The ultra-low thermal shrinking polyurethane ultrafine fiber base cloth has an ultralow thermal shrinking rate, the thermal shrinking value of a base cloth finished product is 0.1-1.5%, and the crease is smooth. The ultra-low thermal shrinking polyurethane ultrafine fiber base cloth can meet the high-temperature using demand and can meet the high-temperature dry method veneering demand.

Owner:江苏华峰超纤材料有限公司

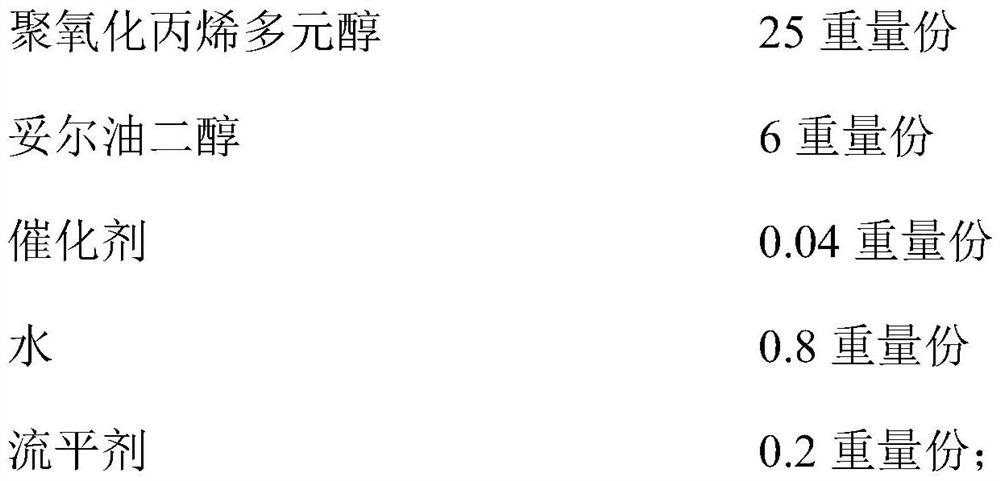

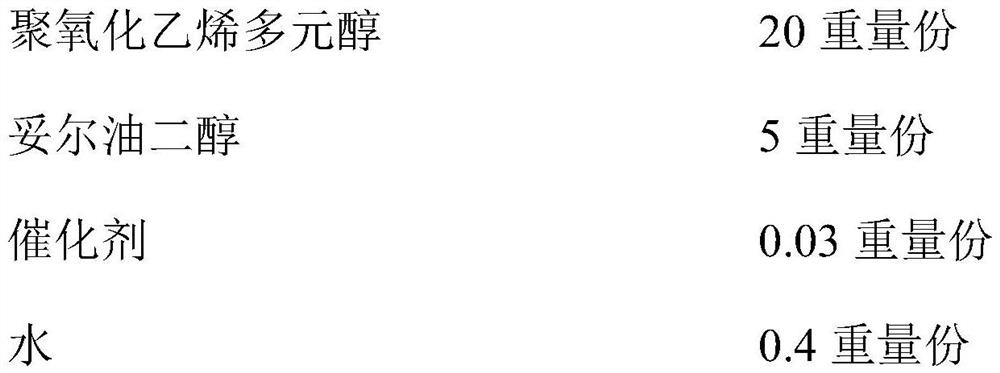

Waterborne polyurethane composite material for shoes and preparation method thereof

PendingCN114737404AFine creaseMeet the flex resistance performance requirementsTextile/flexible product manufactureTextiles and paperPolymer chemistrySolvent free

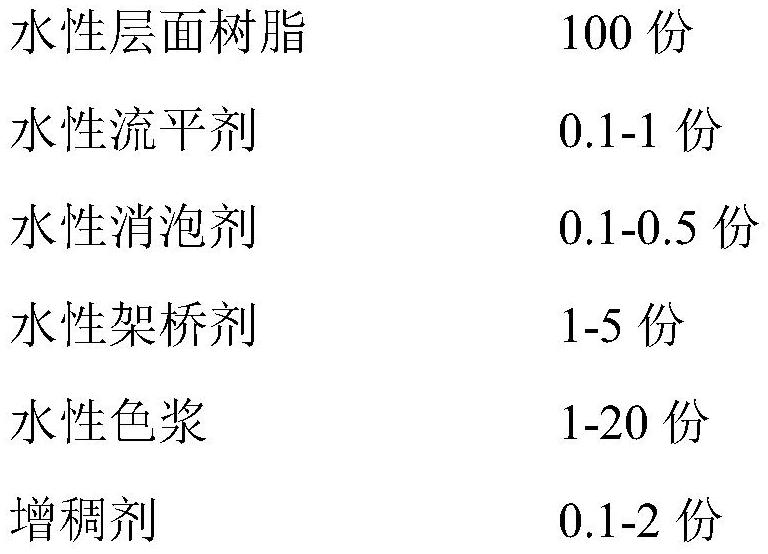

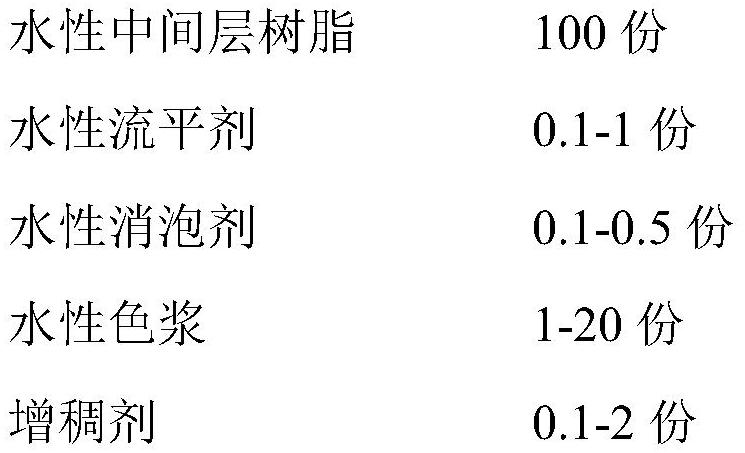

The invention provides a waterborne polyurethane composite material for shoes. The waterborne polyurethane composite material comprises a surface layer, a middle layer, a bonding layer and a base cloth layer which are sequentially bonded from top to bottom, the surface layer is prepared from water-based surface layer resin slurry; the middle layer is made of water-based middle layer resin slurry; and the bonding layer is made of solvent-free resin slurry. The waterborne polyurethane composite material for the shoes, disclosed by the invention, has relatively high stripping force and good folding resistance; according to the preparation method, the use of an organic solvent DMF is avoided, the DMF is not contained in the finished product, and the prepared product meets the requirement that the DMF amount is controlled within 50ppm of customers, and belongs to a green and environment-friendly product. The invention further provides a preparation method of the composite material for the waterborne polyurethane shoes, the steps of a wet method are reduced, foaming of the solvent-free resin is directly used for replacing wet-method base manufacturing, and the effects of energy conservation and emission reduction are achieved.

Owner:ZHEJIANG HEXIN NEW MATERIAL CO LTD

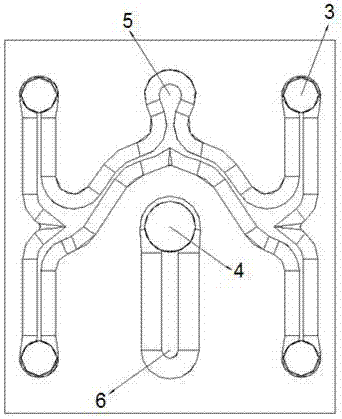

Hole lotus fiber spinning components

ActiveCN104775171BIncrease coverageHigh strengthHollow filament manufactureFilament/thread formingYarnEngineering

The invention discloses a lotus-root-shaped fiber spinning pack and belongs to the technical field of spinning pack equipment. The lotus-root-shaped fiber spinning pack comprises ten distributing plates which are fastened together by using fourteen high-strength bolts. Two high-molecular polymers A and B pass through respective flow passages in each distributing plate and are cooled by air when the polymers exit the last distributing plate to form a plurality of yarns with one component enclosed by the other component. Lotus-root-shaped fibers produced by using the lotus-root-shaped fiber spinning pack have the advantages that the coverage is high, the strength, bonding performance and specific surface area are better, the creases of leather products produced after post-processing are delicate, the formability is good, the anti-aging performance is good and the wearing comfort is good.

Owner:LINYI DAZHENG SPECIAL FIBER NEW MATERIALS

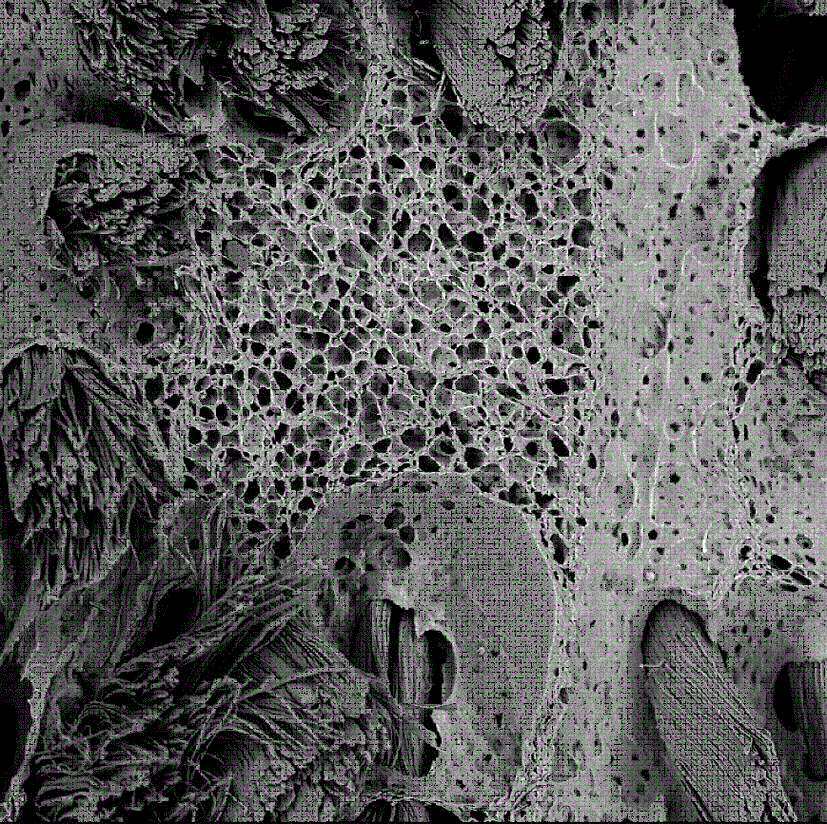

Cowhide-like microfiber synthetic leather and its manufacturing method

ActiveCN105463865BImprove plasticityGood slow rebound effectConjugated synthetic polymer artificial filamentsLow-density polyethyleneSlurry

The invention discloses cowhide-imitated microfibre synthetic leather and a manufacturing method thereof. The manufacturing method comprises the following steps: (1) pasting a low-density polyethylene film on one surface of a non-woven fabric A by hot pressing, thus obtaining a non-woven fabric B covered with the film at a single side; (2) impregnating the non-woven fabric B with wet-process polyurethane resin slurry, then solidifying and washing with water, thus obtaining composite base cloth C; (3) drawing out the composite base cloth C obtained in step (2) in a decrement way, and meanwhile removing the low-density polyethylene film to obtain base cloth D, and oiling to obtain the cowhide-imitated microfibre synthetic leather. While the strong genuine leather feeling of microfibre leather is ensured, a good slow-springback effect is also achieved, creases are fine and smooth, the density of a product has obvious gradient change, and the product has good air permeability, moisture penetrability and watertightness; the warp / weft elongation error of the product is less than or equal to 20 percent, the overall elasticity is little, the size stability is excellent, and fatigue deformation difficultly occurs; compared with existing genuine leather-imitated microfibre leather, the cost is lowered by 5 percent to 15 percent.

Owner:HUAFON MICROFIBER SHANGHAI

High springback wet method polyurethane resin for superfine fiber chemical leather

The invention relates to high resilience wet urethane resin for superfine fiber synthetic leather, which is mainly composed of polyether or polyester polyol, chain extenders and diisocyanate, and the mol ratio of the components is 1 of the polyester polyol, 1.5 to 3 of the chain extenders and 2.5 to 4 of diisocyanate. The high resilience wet urethane resin has the advantages that base cloth impregnated by the urethane resin has good resilience, strong real leather feeling, subtle lines of the base cloth after being reduced in weight, split, expanded, enlarged in size, dried, oiled and kneaded, the lines of the shoes made of shoe synthetic leather (especially for sports shoes and casual shoes) prepared by the base cloth, which are generated during wearing, can automatically restore due to the good resilience, the gauffer of the shoe upper is small, therefore the shoes can have good shape, and the quality is lifted to a higher level.

Owner:HUAFON MICROFIBER SHANGHAI

Sheet-like material

InactiveUS20190368124A1Good flexibilityImprove wrinkle resistanceCoatingsTextiles and paperElastomerSingle fiber

The present invention provide a sheet-like material having a highly soft texture, and further having high crease resistance while being soft. The sheet-like material of the present invention is a sheet-like material which includes a nonwoven fabric containing ultrafine fibers having an average single fiber diameter of 0.3 to 7 μm, and an elastomer, and having nap on a surface, in which the elastomer has a porous structure, and the porous structure has a proportion of micropores with a pore size of 0.1 to 20 μm of 60% or more in all pores.

Owner:TORAY IND INC

Flexible electromagnetic wave shielding material, electromagnetic wave shielding type circuit module comprising same and electronic device furnished with same

ActiveUS10945358B2Increase flexibilityIncrease elasticityElectroconductive/antistatic filament manufactureShielding materialsFiberHigh density

Provided is a flexible electromagnetic wave shielding material. An electromagnetic wave shielding material according to an embodiment of the present invention is implemented to include a conductive fiber web including a conductive composite fiber including a metal shell part covering an outside of a fiber part such that the conductive composite fiber forms multiple pores; and a first conductive component provided in at least some of the pores. The electromagnetic wave shielding material is so excellent in flexibility, elasticity, and creasing / recovery that the electromagnetic wave shielding material may be freely changed in shape, and can be brought in complete contact with a surface where the electromagnetic wave shielding material is intended to be disposed even if the surface has a curved shape such as an uneven portion or a stepped portion, thus exhibiting excellent electromagnetic wave shielding performance. Also, it is possible to prevent deterioration of the electromagnetic wave shielding performance even with various shape changes. Furthermore, even if parts are provided in a narrow area at a high density, the electromagnetic wave shielding material can be brought into complete contact with the mounted parts by overcoming a tight space between the parts and a stepped portion. Thus, the present invention can be easily employed for a light, thin, short, and small or flexible electronic device.

Owner:AMOGREENTECH CO LTD

A kind of ultra-soft protein wet-process resin and its preparation method and application

ActiveCN106479095BStrong sense of spongeFine creasePolyurea/polyurethane coatingsTextiles and paperPolyesterPolymer science

The invention relates to a supersoft protein wet-process resin, which consists of 5%-10% of polyester / polyether polyol, 0.3%-0.7% of double-terminated hydroxyl polyether modified silicone oil, 0.3%-1% of ethylene glycol, diphenyl Methyl methane-4,4-diisocyanate 2%~5%, polyvinyl alcohol powder 15%~20%, polyamide wax 0.15%~0.25%, N,N-dimethylformamide 68%~73% made. The invention also discloses a preparation method of the ultra-soft protein wet-process resin. The wet-process synthetic leather bass made of the polyurethane polyvinyl alcohol blended wet-process resin synthesized by the above formula and process has a strong sponge feel, a honeycomb-like cell structure similar to leather protein fibers, fine creases, and a texture similar to leather protein fibers. The softness, comfort, nature and warmth of the fiber.

Owner:SHANGHAI HUIDE TECH CO LTD

Imitation sheepskin ultrafine fiber polyurethane synthetic leather and manufacturing method thereof

InactiveCN103451959BGood flexibilityStrong skin feelingLamination ancillary operationsSynthetic resin layered productsFiberSurface layer

The invention discloses imitation sheepskin ultrafine fiber polyurethane synthetic leather and a manufacturing method thereof. The manufacturing method comprises the following steps: (1) applying oil to raw base cloth A and drying to obtain base cloth B; (2) bonding a sizing agent of surface layer dry-method polyurethane resin to the base cloth B obtained in the step (2) through a polyurethane bonder by a release paper dry-method film-shifting and surface-making technology, and stripping release paper to obtain the imitation sheepskin ultrafine fiber polyurethane synthetic leather. According to the method, the moderately soft base cloth is selected, the base cloth subjected to oil application is high in softness and leather feel, and the surface-overlaid ultrafine fiber polyurethane synthetic leather obtained through a dry-method surface-making process is good in fold lines and smooth feel. The imitation sheepskin ultrafine fiber polyurethane synthetic leather provided by the invention is exquisite in fold lines and smooth in hand feel, has a very good genuine leather feel and successfully solves the problem that exquisite fold lines and high softness of conventional imitation genuine leather ultrafine fiber synthetic leather cannot be compatible.

Owner:HUAFON MICROFIBER SHANGHAI

Water-based high-transparency mirror ecological synthetic leather and preparation method thereof

InactiveCN113308906AGood physical propertiesGood translucent effectCoatingsTextiles and paperSolvent freeSolid content

The invention discloses water-based high-transparency mirror ecological synthetic leather. The leather comprises a high-solid-content resin layer having a first surface and a second surface opposite to the first surface, a mirror water-based surface layer arranged on the first surface of the high-solid-content resin layer, a solvent-free resin layer arranged on the second surface of the high-solid-content resin layer, and a base cloth layer attached to the solvent-free resin layer. Meanwhile, the invention also provides a preparation method of the water-based high-transparency mirror ecological synthetic leather. The water-based high-transparency mirror ecological synthetic leather obtained by the method comprehensively achieves the high physical property effect of a finished product, the DMF residue test of the finished product is less than or equal to 50 ppm, and the surface is good in transparency effect, flat and fine in crease.

Owner:ZHEJIANG HEXIN NEW MATERIAL CO LTD

A kind of preparation method of high cotton feeling microfiber sofa leather bass

ActiveCN109537291BVoluptuousFine creaseFibre typesConjugated synthetic polymer artificial filamentsSpinningPulp and paper industry

The invention belongs to the technical field of preparation of ultrafine fiber synthetic leather, and in particular relates to a preparation method of ultrafine fiber sofa leather bass, comprising the following processing steps: spinning, non-woven fabric, non-woven fabric shaping, wet impregnation, extraction, and drying Oiling, kneading and finishing. The preparation method of the present invention adopts novel polyurethane to wet impregnate the microfiber non-woven fabric, and is equipped with a reasonable superfiber production process, so that the microfiber bass prepared by the present invention has the characteristics of plump flesh and relatively delicate creases, and can be Improve the grade of microfiber sofa leather, comparable to calfskin and goatskin, greatly reduce the consumption of raw materials, increase the recycling value of waste polyethylene, and improve product quality, and the economy is relatively high.

Owner:重庆双象超纤材料有限公司

Solvent-free polyurethane resin and preparation method and application thereof

ActiveCN113527623AIncreased elastic elongationGood compatibilityTextiles and paperPolymer sciencePolyol

The invention provides solvent-free polyurethane resin and a preparation method and application thereof. The solvent-free polyurethane resin comprises a component A and a component B; the component A comprises polyether polyol and tall oil glycol in specific parts; the component B comprises a polyurethane prepolymer; according to the solvent-free polyurethane resin, tall oil glycol containing a large side chain is added into the component A to replace traditional micromolecular glycol to serve as a chain extender, so that the compatibility among all the components is effectively improved, the lubricity of a molecular chain is improved, the finally obtained finished synthetic leather is soft and full in hand feeling, and the grade of the synthetic leather product is improved.

Owner:ZHEJIANG HUAFON SYNTHETIC RESIN

Ultra-low thermal shrinkage polyurethane superfine fiber base cloth and preparation method thereof

ActiveCN109518467BUltra-low heat shrinkageMeet veneer requirementsPattern makingFibre typesDiethylene glycol monobutyl etherPolyester

The invention discloses an ultra-low thermal shrinkage polyurethane microfiber base cloth and a preparation method thereof. The preparation method of the ultra-low thermal shrinkage polyurethane ultrafine fiber base cloth comprises the following steps: making nylon 6 or polyester, polyethylene or styrene into The non-woven fabric formed by sea-island short fiber is impregnated in wet slurry, then coagulated and washed with water, and then the polyethylene or styrene is decremented in hot toluene to obtain a wet cloth, and then the wet cloth is impregnated Continuous kneading and drying in the oiling solution can obtain the ultra-low heat shrinkage polyurethane microfiber base cloth; the oiling solution contains amino silicone oil, isomerized decanol polyoxyethylene ether, isomerized decanol polyoxyethylene ether, isomerized decanol Triol ethoxylates, diethylene glycol monobutyl ether and water. The invention has an ultra-low thermal shrinkage rate, the thermal shrinkage value of the finished base fabric is 0.1-1.5%, and the features of fine creases can meet the requirements of high-temperature use and high-temperature dry veneering.

Owner:江苏华峰超纤材料有限公司

A kind of production method of high-physical superfiber velvet feel lamb grain synthetic leather

ActiveCN108532310BStrong skin feelingStrong cashmere effectTextiles and paperPolymer scienceEngineering

Owner:ANAN CHINA

Microfiber superfine fold line bonding layer resin and production process thereof

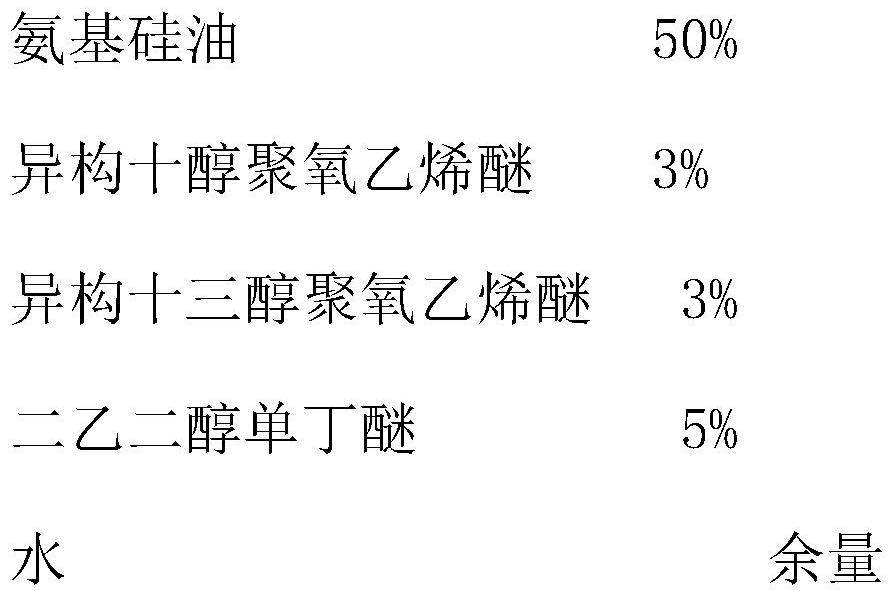

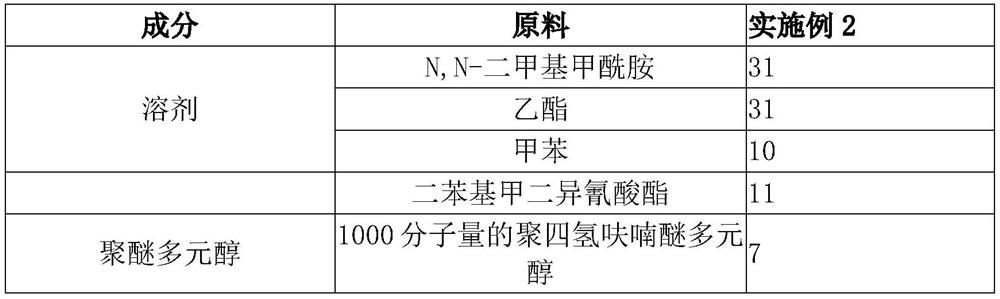

InactiveCN113105602AFinished leather feels softImprove flexural strengthTextiles and paperPolyesterPolymer science

The invention relates to a microfiber superfine crease bonding layer resin and a production process thereof. The microfiber superfine crease bonding layer resin is prepared from 57 to 70 parts of a solvent, 9 to 11 parts of diphenylmethane diisocyanate, 9 to 12 parts of methylbenzene, 26 to 33 parts of polyhydric alcohol, 0.8 to 1.2 parts of a chain extender, 0.5 to 1.0 part of a coupling agent, 1.0 to 1.5 parts of a catalyst, 0.5 to 0.9 part of a promoter and 0.4 to 0.8 part of a terminating agent. Wherein the content of the N, N-dimethylformamide is 28 to 36 parts, and the content of the ethyl ester is 29 to 34 parts; and the polyol comprises polyether polyol and polyester polyol, and the weight part ratio of the polyether polyol to the polyester polyol is 1: 3. According to the present invention, the resin leather forming hand feeling is soft, the resin crosslinking degree is high, and the folding line after the resin leather forming is superfine.

Owner:浙江诚迅新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com