Water-based high-transparency mirror ecological synthetic leather and preparation method thereof

A synthetic leather, water-based technology, applied in the field of polyurethane leather, can solve the problems of crease effect, lack of top brightening effect, high residual DMF solvent, reduced mirror translucent effect, etc. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

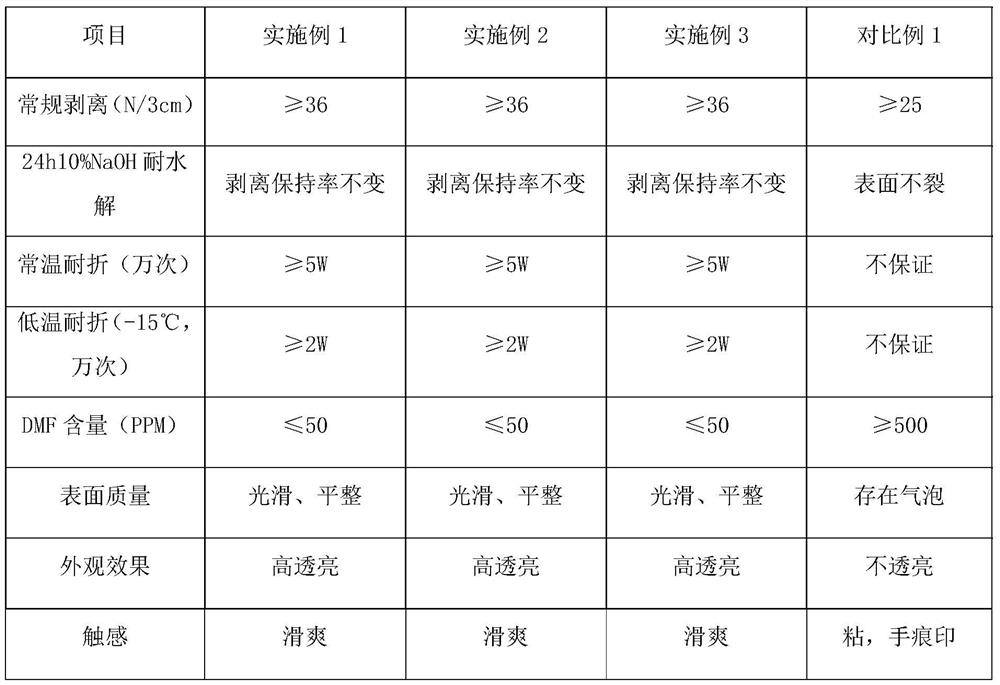

Examples

preparation example Construction

[0027] Among them, the preparation method of the water-based high-transparency mirror-surface ecological synthetic leather includes the following steps: preparing a high-solid-content resin layer slurry, preparing a mirror-surface water-based surface layer slurry, and preparing a solvent-free resin layer slurry; The first layer of slurry is coated on the release paper, and the coating knife position is 0.03-0.15mm. After drying, a mirror-like water-based surface layer is formed. The thickness of the mirror-like water-based surface layer is 0.01-0.1mm; the prepared high-solid content resin The first layer of slurry is coated on the mirror water-based surface layer, the coating knife position is 0.1-0.5mm, and then it is dried in sections. The drying temperature of the first stage is 80-100 ℃, and the drying temperature of the second stage is 100 -120°C, the drying temperature of the third stage is 155-175°C, the drying temperature of the fourth stage is 155-175°C, and the drying...

Embodiment 1

[0034] The preparation method of the water-based high-transparency mirror ecological synthetic leather comprises the following steps:

[0035] Preparation of high solid content resin layer slurry: the following raw materials by weight: 100 parts of 100% solid content isocyanate prepolymer (curing modulus at 3-5Mpa, 100% modulus), 3 parts of polyamine small molecule chain extension Agent, 0.1 part of 100% solid content silicone modified surfactant, 1 part of 100% solid content solvent-free colorant are mixed with a certain amount of water to form a high solid content resin layer slurry.

[0036] Prepare the mirror surface water-based surface layer slurry: the following raw materials by weight: 100 parts of water-based polyurethane resin, 0.1 part of water-based leveling agent BYK-346, 0.1 part of water-based defoamer BYK-024, 1 part of isocyanate-based water-based bridging agent, 3 parts of water-based color paste are mixed with a certain amount of water to form a mirror surfac...

Embodiment 2

[0043] The preparation method of the water-based high-transparency mirror ecological synthetic leather comprises the following steps:

[0044] Preparation of high solid content resin layer slurry: the following raw materials in parts by weight: 100 parts of 100% solid content isocyanate prepolymer (curing modulus at 3-5Mpa, 100% modulus), 10 parts of polyamine small molecule chain extension agent, 1 part of 100% solid content silicone modified surfactant, 5 parts of 100% solid content solvent-free colorant and a certain amount of water are mixed to form a high solid content resin layer slurry.

[0045] Prepare the mirror surface water-based surface layer slurry: The following raw materials are used in parts by weight: 100 parts of water-based polyurethane resin, 0.5 parts of water-based leveling agent BYK-346, 0.3 parts of water-based defoamer BYK-024, 3 parts of isocyanate-based water-based bridging agent, 10 parts of water-based color paste are mixed with a certain amount of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com