Preparation method of high-cotton-feeling micro-fiber sofa leather base

A technology of sofa leather bass and microfiber, which is applied in the direction of fiber type, fiber treatment, and conjugated synthetic polymer artificial filament, etc., which can solve the problems of reducing the use time of recycling equipment, easy collapse of cells, and high cost, so as to improve recycling Value, improve product quality, improve the effect of grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A preparation method of high-cotton feeling microfiber sofa leather bass, comprising the following steps:

[0024] (1) Preparation of "sea-island" type composite fiber: Nylon 6 (PA6) and linear low-density polyethylene (LDPE), according to the ratio of PA6: LDPE = 50: 50, obtained through the mixed melt extrusion method The linear density is 6dtex, "island in the sea" type composite staple fiber with a length of 51mm, in which PA6 is the "island" and LDPE is the "sea";

[0025] (2) The preparation of microfiber nonwoven fabric: adopt the composite staple fiber in the step (1), through operations such as opening, carding, laying a net, acupuncture, obtain the grammage and be 450g / m 2 of non-woven fabrics;

[0026] (3) Ironing and setting: heat the non-woven fabric in step (2) at 155°C for 3 minutes, the LDPE will be softened, and then passed through a pressing roller to make a density of 0.28g / cm 3 of non-woven fabrics;

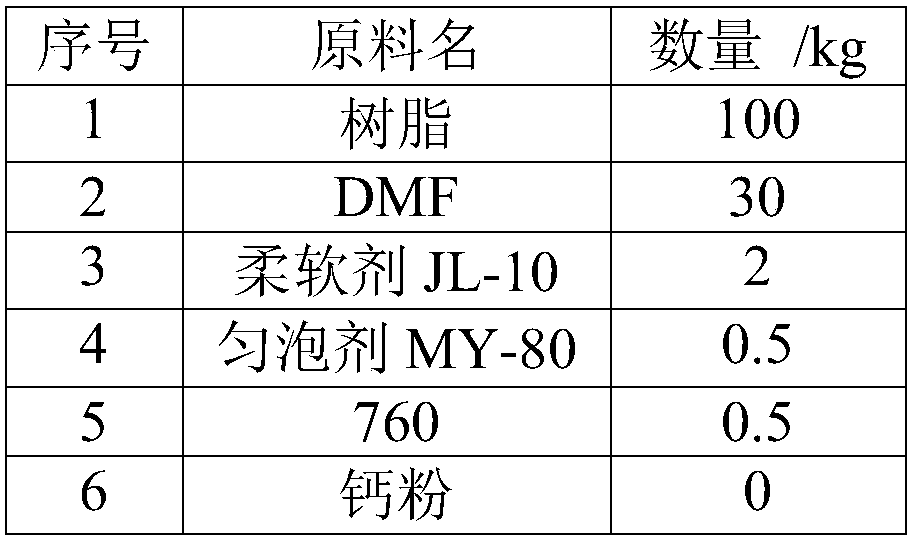

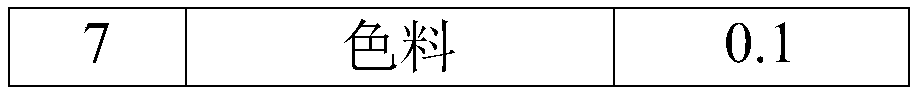

[0027] (4) Impregnation: prepare an impregnati...

Embodiment 2

[0035] A preparation method of high-cotton feeling microfiber sofa leather bass, comprising the following steps:

[0036] (1) Preparation of "sea-island" type composite fiber: Nylon 6 (PA6) and linear low-density polyethylene (LDPE), according to the ratio of PA6: LDPE = 53: 47, obtained through the mixed melt extrusion method The linear density is 6.0dtex, "sea island" type composite staple fiber with a length of 51mm, in which PA6 is used as the "island" and LDPE is used as the "sea";

[0037] (2) The preparation of microfiber nonwoven fabric: adopt the composite staple fiber in the step (1), through operations such as opening, carding, laying a net, acupuncture, obtain the grammage and be 450g / m 2 of non-woven fabrics;

[0038] (3) Ironing and setting: heat the non-woven fabric in step (2) at 155°C for 3 minutes, the LDPE will be softened, and then passed through a pressing roller to make a density of 0.28g / cm 3 of non-woven fabrics;

[0039] (4) Impregnation: prepare an...

Embodiment 3

[0047] A preparation method of high-cotton feeling microfiber sofa leather bass, comprising the following steps:

[0048](1) Preparation of "sea-island" type composite fiber: Nylon 6 (PA6) and linear low-density polyethylene (LDPE), according to the ratio of PA6: LDPE = 50: 50, obtained through the mixed melt extrusion method The linear density is 5.5dtex, "sea island" type composite staple fiber with a length of 51mm, in which PA6 is used as the "island" and LDPE is used as the "sea";

[0049] (2) The preparation of microfiber nonwoven fabric: adopt the composite staple fiber in the step (1), through operations such as opening, carding, laying a net, acupuncture, obtain the grammage and be 450g / m 2 of non-woven fabrics;

[0050] (3) Ironing and setting: heat the non-woven fabric in step (2) at 155°C for 3 minutes, the LDPE will be softened, and then passed through a pressing roller to make a density of 0.28g / cm 3 of non-woven fabrics;

[0051] (4) Impregnation: prepare an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com