Microfiber superfine fold line bonding layer resin and production process thereof

A bonding layer and microfiber technology, applied in the field of resin materials, can solve the problems of poor crease resistance of yangbar leather, and achieve the effect of safe and reliable processing and enhanced flexural strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

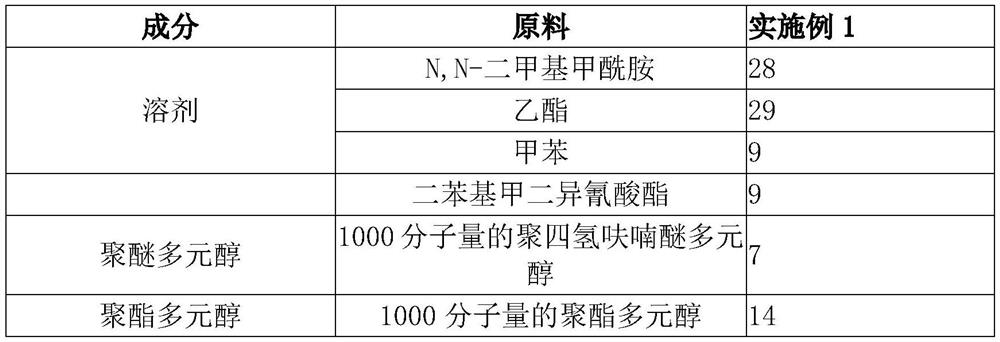

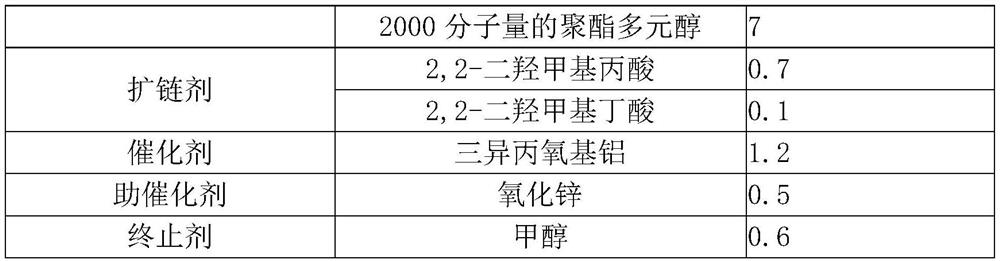

[0050] The resin raw material composition and proportioning that embodiment 1 provides are shown in Table 1.

[0051] Raw material composition and proportioning of table 1 embodiment 1

[0052]

[0053]

[0054] Wherein: the molecular weight of polytetrahydrofuran ether polyol is 1000.

[0055] The preparation process includes the following steps:

[0056] S1: N,N-dimethylformamide, toluene, polytetrahydrofuran ether polyol, polyester polyol, 2,2-dimethylol propionic acid, 2,2-dimethylol butyric acid, catalyst, Add co-catalyst etc. into the reactor and stir for 5 minutes, the reaction temperature is controlled at 45°C;

[0057] S2: Add excess diphenylmethane diisocyanate according to 1:1.05, control the reaction temperature at 72°C, and control the reaction time at 60 minutes;

[0058] S3: When the viscosity of the material in step S2 reaches 40,000 cps / 25°C, continue to add an appropriate amount of N,N-dimethylformamide, a small amount of ethylene glycol and a small ...

Embodiment 2

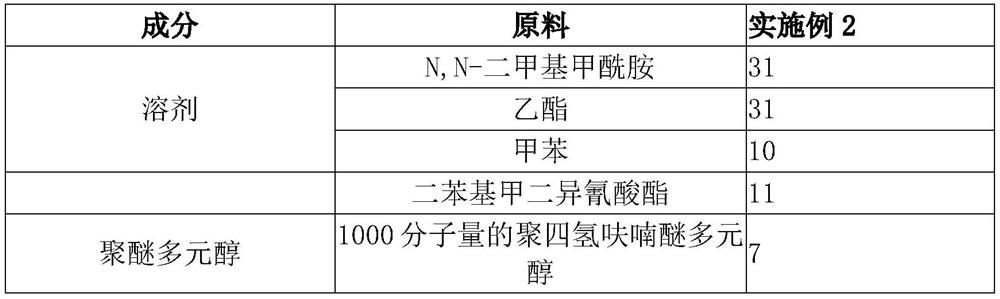

[0067] The raw material composition and proportioning of the resin raw materials provided in Example 2 are shown in Table 2, and the preparation method is the same as in Example 1.

[0068] Raw material composition and proportioning of table 2 embodiment 2

[0069]

[0070]

[0071] Wherein: the molecular weight of polytetrahydrofuran ether polyol is 1000.

Embodiment 3

[0073] The raw material composition and proportioning of the resin raw materials provided in Example 3 are shown in Table 3, and the preparation method is the same as in Example 1.

[0074] Raw material composition and proportioning of table 3 embodiment 3

[0075]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com