Environment-friendly slow-rebound polyurethane synthetic leather for sofa furniture and preparation method of environment-friendly slow-rebound polyurethane synthetic leather

A slow-rebound, environmentally-friendly technology, applied in furniture parts, home appliances, applications, etc., can solve problems such as difficulty in meeting environmental protection requirements and consumer needs, poor physical properties and hydrolysis resistance, and damage to the physical and mental health of staff , to achieve the effects of moderate modulus, shortened reaction time, and excellent environmental performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

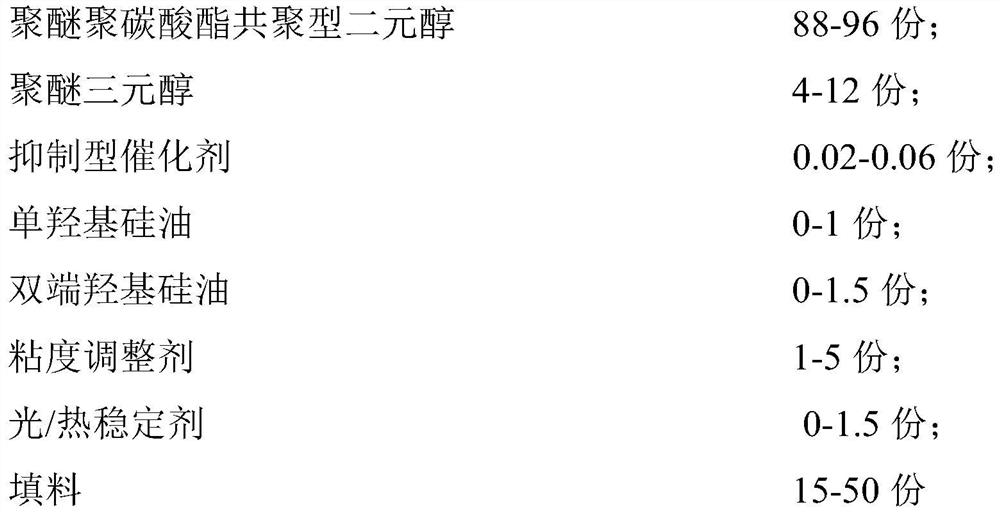

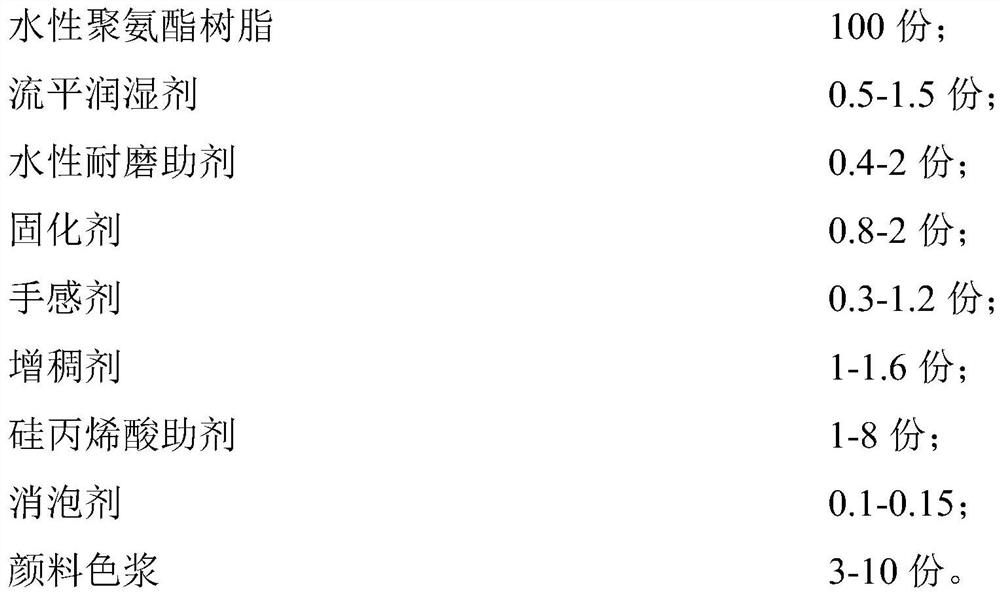

Method used

Image

Examples

Embodiment 1

[0059] First, add 0.5 part of Silok 8030F, 0.6 part of SY-3520, 0.5 part of Silok 50, 0.5 part of 2794, 0.5 part of HYC-100, 0.1 part of BF-2010, 2 parts of RU-911, 1 part of U-605 into 50 parts of Leasys 3250 and 50 parts of PU-209-7 mixed with water-based resin, then add 8 parts of water-based pigment color paste to fully stir and mix evenly, then vacuumize, and then evenly apply and scrape on the front of the release paper as the surface layer, the surface layer slurry The coating thickness of the layer is 0.1mm; then add 0.3 parts of Silok 8030F, 0.4 parts of SY-3520, 0.3 parts of 2794, 0.5 parts of HYC-100, 0.1 parts of BF-2010, 1 part of U-605 into 50 parts of Tekspros 5215 and 50 10 parts of JF-PDY-847HY mixed with water-based resin, then add 10 parts of pigment color paste to fully stir and mix evenly, then vacuumize, and then evenly smear and scrape on the surface layer to prepare the middle layer. The thickness of the middle layer slurry layer is 0.13 mm; drying at a...

Embodiment 2

[0064] First, add 1.0 part of Silok 8030F, 1 part of SY-3520, 0.8 part of Silok 50, 1.0 part of 2794, 0.5 part of HYC-100, 0.1 part of BF-2010, 5 parts of RU-911, 1.2 part of U-605 into 60 parts of Leasys 3250 and 40 parts of PU-209-7 mixed with water-based resin, then add 10 parts of water-based pigment color paste to fully stir and mix evenly, then vacuumize, and then evenly apply and scrape on the front of the release paper as the surface layer, the surface layer slurry The coating thickness of the layer is 0.13mm; then add 0.5 parts of Silok 8030F, 1 part of SY-3520, 0.5 parts of 2794, 0.8 parts of HYC-100, 0.15 parts of BF-2010, 0.8 parts of U-605 into 50 parts of Tekspros 5215 and 50 parts 10 parts of JF-PDY-847HY mixed with water-based resin, then add 10 parts of pigment color paste to fully stir and mix evenly, then vacuumize, and then evenly smear and scrape on the surface layer to prepare the middle layer. The thickness of the middle layer slurry layer is 0.15 mm; dr...

Embodiment 3

[0069] First, add 1.5 parts of Silok 8030F, 2 parts of SY-3520, 1.2 parts of Silok 50, 1.0 part of 2794, 1.0 part of HYC-100, 0.15 part of BF-2010, 6 parts of RU-911, 1 part of U-605 into 60 parts of Leasys 3250 and 40 parts of PU-209-7 mixed with water-based resin, then add 8 parts of water-based pigment color paste to fully stir and mix evenly, then vacuumize, and then evenly apply and scrape on the front of the release paper as the surface layer, the surface layer slurry The coating thickness of the layer is 0.15mm; then add 0.8 parts of Silok 8030F, 1.5 parts of SY-3520, 1.0 parts of 2794, 0.5 parts of HYC-100, 0.12 parts of BF-2010, 1.2 parts of U-605 to 40 parts of Tekspros 5215 and 60 10 parts of JF-PDY-847HY mixed with water-based resin, then add 10 parts of pigment color paste to fully stir and mix evenly, then vacuumize, and then evenly squeegee on the surface layer to prepare the middle layer. The thickness of the middle layer slurry layer is 0.15 mm; drying at a te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com