High solid content two-liquid type adhesive layer polyurethane resin and preparation method thereof

A polyurethane resin, high solids technology, applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., to achieve the effect of reducing usage, fine creases, and reducing negative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The raw materials used in this embodiment and their weight are shown in Table 1.

[0027] Table 1

[0028] raw material name Weight: kg kmol Polyethylene adipate glycol butanediol copolyester diol (number average molecular weight 1000) 100 0.1 Poly(Neopentyl Glycol Adipate) Diol (Number Average Molecular Weight 1000) 200 0.2 Toluene diisocyanate 60.09 0.345 blocking agent butanone oxime 7.84 0.09 Solvent DMF 40.88 / Total 408.81 /

[0029] The preparation steps of the high-solid two-component adhesive layer polyurethane resin of the present embodiment are as follows:

[0030] 1), put 100kg polyethylene adipate butanediol copolyester diol, 200kg polyneopentyl adipate diol, 40.88kg dimethylformamide into the reaction kettle, stir evenly at 50°C ;

[0031] 2), put 60.09kg of toluene diisocyanate into the reaction kettle at one time, control the reaction temperature at 65°C, react under normal pressure, use di-n-b...

Embodiment 2

[0034] The raw materials used in this embodiment and their weight are shown in Table 2.

[0035] Table 2

[0036] raw material name Weight: kg kmol Diethylene glycol adipate copolyester diol (number average molecular weight 3000) 210 0.07 Polypropylene oxide ether glycol (number average molecular weight 3000) 105 0.035 Isophorone diisocyanate 33.84 0.1522 Blocking agent 3,5-dimethylpyrazole 9.07 0.0944 Solvent dimethylacetamide 89.48 / Total 447.39 /

[0037] The preparation steps of the high-solid two-component adhesive layer polyurethane resin of the present embodiment are as follows:

[0038] 1), put 210kg polyethylene adipate diethylene glycol copolyester diol, 105kg polypropylene oxide ether diol, 89.48kg dimethylacetamide into the reaction kettle, stir evenly at 60°C;

[0039] 2) Put 33.84kg of isophorone diisocyanate into the reactor at one time, control the reaction temperature at 105°C, react under normal pre...

Embodiment 3

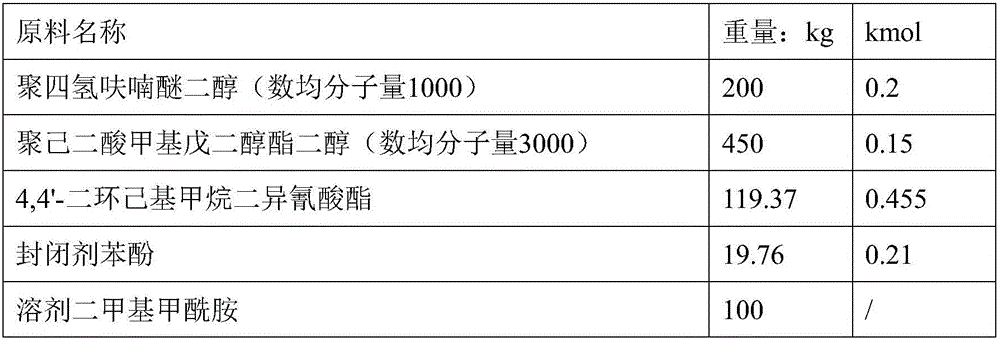

[0042] The raw materials used in this embodiment and their weight are shown in Table 3.

[0043] table 3

[0044]

[0045]

[0046] The preparation steps of the high-solid two-component adhesive layer polyurethane resin of the present embodiment are as follows:

[0047] 1), put 200kg polytetrahydrofuran ether diol, 450kg polymethylpentanediol adipate diol, 100kg dimethylformamide, 39.26kg dimethylacetamide into the reaction kettle, stir evenly at 55°C;

[0048] 2) Put 119.37kg of 4,4'-dicyclohexylmethane diisocyanate into the reactor at one time, control the reaction temperature at 95°C, react under normal pressure, use di-n-butylamine titration to track and detect the content of isocyanate groups, and keep warm until When the content of isocyanate group is constant, lower the temperature to 63°C;

[0049] 3) Add 19.76 kg of phenol into the reaction kettle and react at 82° C. under normal pressure for 30 minutes to obtain the high solid content two-component adhesive l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com