Environment-friendly space leather and preparation method and application thereof

A space leather, environment-friendly technology, applied in the field of leather, can solve the problem that the tear strength of space leather needs to be further improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] In this embodiment, an environment-friendly space leather is provided. The environment-friendly space leather comprises a water-based polyurethane resin surface layer, a solvent-free polyurethane resin foaming layer and a water-based polyurethane resin impregnated layer from top to bottom.

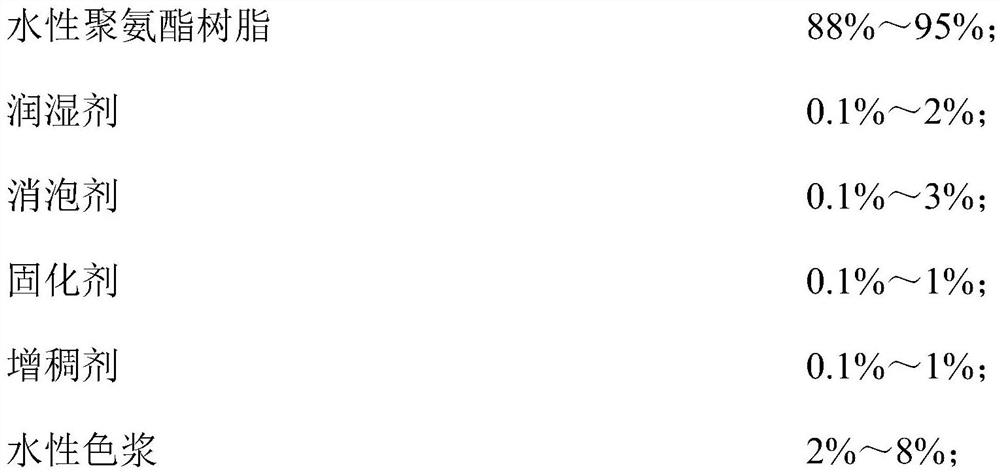

[0083] The water-based polyurethane resin surface layer is obtained by coating the water-based polyurethane resin surface layer compounding liquid on the DE-7 type release paper, and the water-based polyurethane resin surface layer compounding liquid comprises the following components in weight percentage:

[0084]

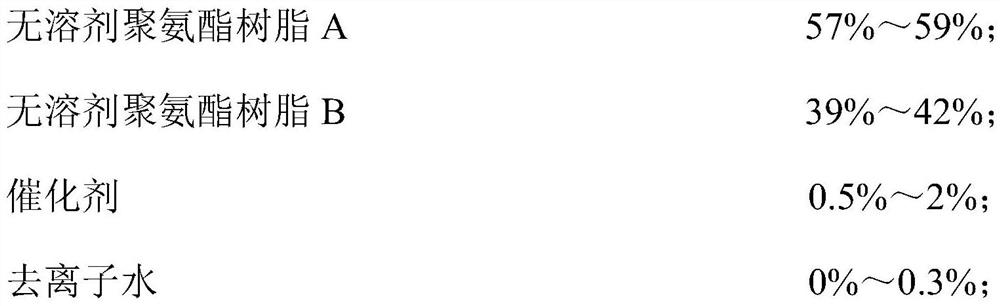

[0085] The raw materials for the preparation of the solvent-free polyurethane resin foam layer include the following components by weight percentage:

[0086]

[0087] The water-based polyurethane resin impregnation layer is obtained by immersing the base cloth in the water-based polyurethane resin impregnation solution, and the water-based polyurethane resin impre...

Embodiment 2

[0099] In this embodiment, an environment-friendly space leather is provided. The environment-friendly space leather comprises a water-based polyurethane resin surface layer, a solvent-free polyurethane resin foaming layer and a water-based polyurethane resin impregnated layer from top to bottom.

[0100] The water-based polyurethane resin surface layer is obtained by coating the water-based polyurethane resin surface layer compounding liquid on the DE-7 type release paper, and the water-based polyurethane resin surface layer compounding liquid comprises the following components in weight percentage:

[0101]

[0102] The raw materials for the preparation of the solvent-free polyurethane resin foam layer include the following components by weight percentage:

[0103] Solvent-free polyurethane resin A (HDPM-9003A) 58%;

[0104] Solvent-free polyurethane resin B (HDPM-9003B) 40%;

[0105] Catalyst (HDPM-9003C) 2%;

[0106] The water-based polyurethane resin impregnation lay...

Embodiment 3

[0118] In this embodiment, an environment-friendly space leather is provided. The environment-friendly space leather comprises a water-based polyurethane resin surface layer, a solvent-free polyurethane resin foaming layer and a water-based polyurethane resin impregnated layer from top to bottom.

[0119] The water-based polyurethane resin surface layer is obtained by coating the water-based polyurethane resin surface layer compounding liquid on the R-8 type release paper, and the water-based polyurethane resin surface layer compounding liquid includes the following components in weight percentage:

[0120]

[0121] The raw materials for the preparation of the solvent-free polyurethane resin foam layer include the following components by weight percentage:

[0122]

[0123] The water-based polyurethane resin impregnation layer is obtained by immersing the base cloth in the water-based polyurethane resin impregnation solution, and the water-based polyurethane resin impregn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specification | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| 100% modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com