Cowhide-like microfiber synthetic leather and its manufacturing method

A manufacturing method and technology of imitating cowhide, applied in the direction of conjugated synthetic polymer man-made filament, textiles and papermaking, etc., can solve the problems of easy fatigue deformation, decreased density of finished products, decreased sensuality, etc. Small elasticity and fine crease effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

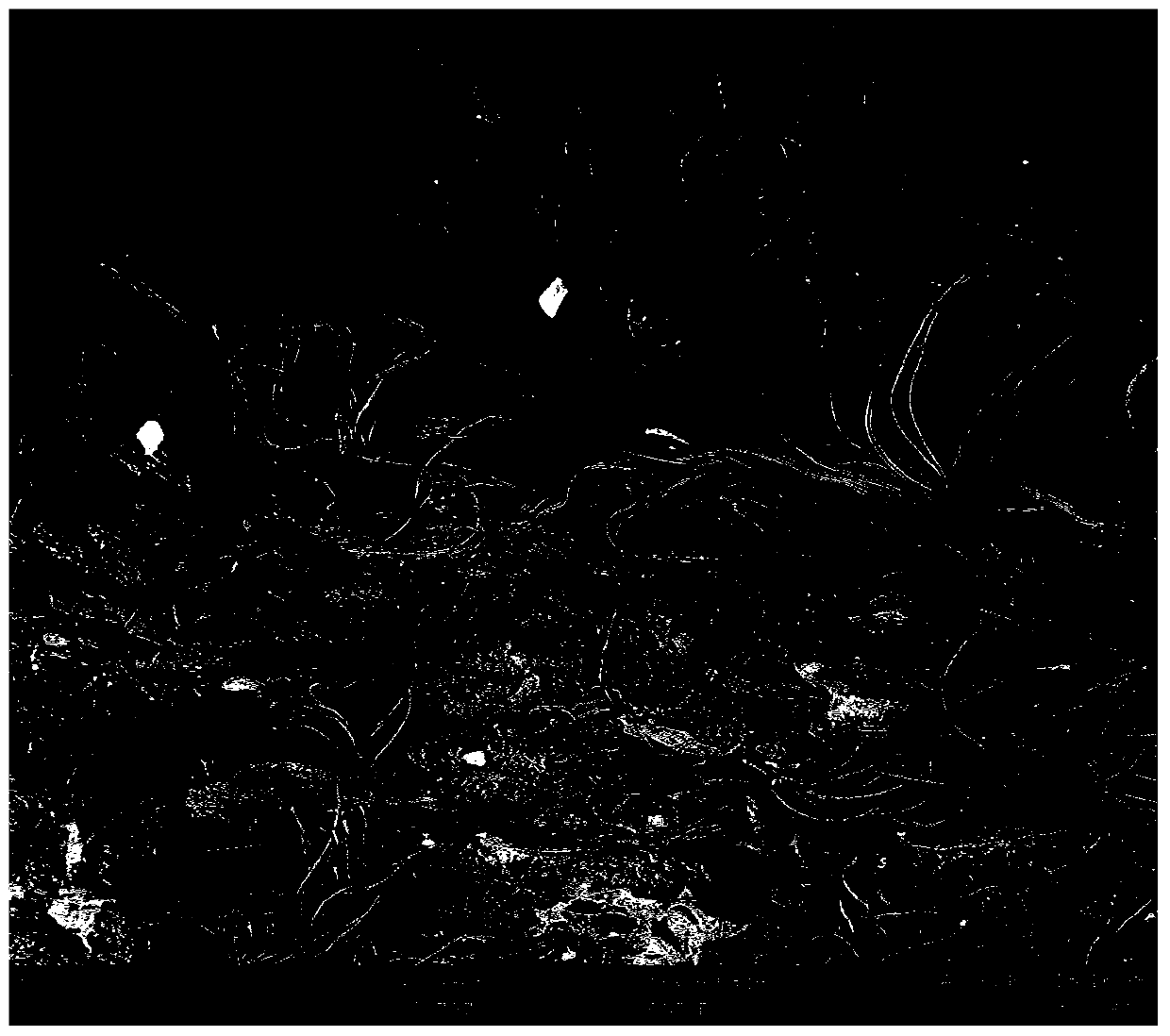

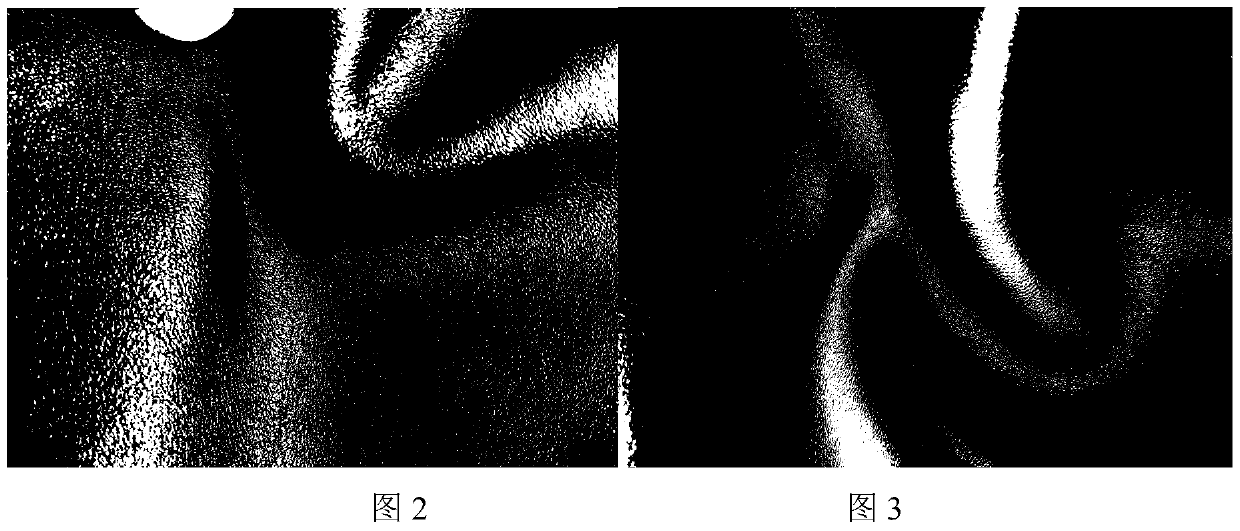

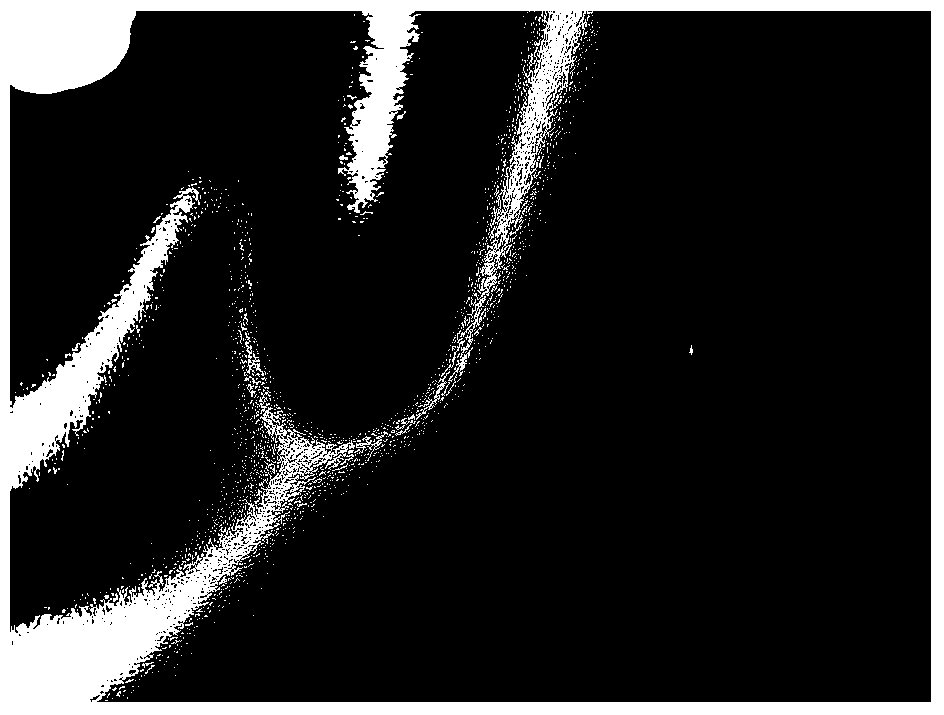

Image

Examples

Embodiment 1

[0040] (1) Adopt 50% nylon and 50% low-density polyethylene to melt-spin through indeterminate islands to obtain short fibers with a length of 5 cm, and needle punch to form 0.20 g / cm 3 The non-woven fabric A, adopts the low-density polyethylene film of 0.1mm thickness to adopt the following process to obtain non-woven fabric B on the CM-3400 type home textile machine:

[0041] Laminating temperature: 100°C;

[0042] Roller pressure: 0.1kgf / cm 2 ;

[0043] Speed: 5m / min;

[0044] Tension of non-woven fabric A: 1kgf / cm 2 ;

[0045] (2) The non-woven fabric B is carried out wet impregnation and coagulation to obtain the composite base cloth C, and the material liquid for impregnation includes the following components in parts by weight: the polyurethane resin for impregnation is 20 parts of all-polyether polyurethane resin, high Rebound polyester polyether copolymer polyurethane resin 80 parts, wood flour 20 parts, JS-BT 0.1 part, DMF 10 parts;

[0046] The full polyether ...

Embodiment 2

[0062] (1) Adopt 70% nylon and 30% low-density polyethylene to obtain 5cm long short fibers by Dingdao melt spinning, and needle punching to form 0.26g / cm 3 The non-woven fabric A, adopts the low-density polyethylene film of 0.3mm thickness to adopt the following process to cover the film on the CM-3400 type home textile machine to obtain the non-woven fabric B:

[0063] Laminating temperature: 220 degrees;

[0064] Roller pressure: 4kgf / cm 2 ;

[0065] Speed: 12m / min;

[0066] Tension of non-woven fabric A: 4kgf / cm 2 ;

[0067] (2) The non-woven fabric B is wet impregnated and coagulated to obtain a composite base fabric C, and the impregnated material liquid includes the following components in parts by mass: 60 parts of all-polyether polyurethane resin, high-resilience polyester polyether 40 parts of copolymerized polyurethane resin, 5 parts of wood flour, 1 part of JS-BT, 18 parts of DMF;

[0068] The all-polyether polyurethane resin (2500 molecular weight) is polyte...

Embodiment 3

[0083] (1) Adopt 55% nylon and 45% low-density polyethylene to obtain 5cm long short fibers by indeterminate island melt spinning, and needle punch to form 0.23g / cm 3 The non-woven fabric A, adopts the low-density polyethylene film of 0.2mm thickness to adopt the following process to cover the film on the CM-3400 type home textile machine to obtain the non-woven fabric B:

[0084] Laminating temperature: 150°C;

[0085] Roller pressure: 3kgf / cm 2 ;

[0086] Vehicle speed: 8.5m / min;

[0087] Tension of non-woven fabric A: 2kgf / cm 2 ;

[0088] (2) The non-woven fabric B is wet impregnated and coagulated to obtain a composite base cloth C, and the impregnated material liquid includes the following components in parts by weight: 45 parts of all-polyether polyurethane resin, high-resilience polyester polyether 55 parts of copolymerized polyurethane resin, 15 parts of aluminum hydroxide, 0.3 parts of JS-BT, 10.63 parts of DMF;

[0089] The all-polyether polyurethane resin (180...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com