Ultra-soft protein-like wet-process resin, and preparation method and application thereof

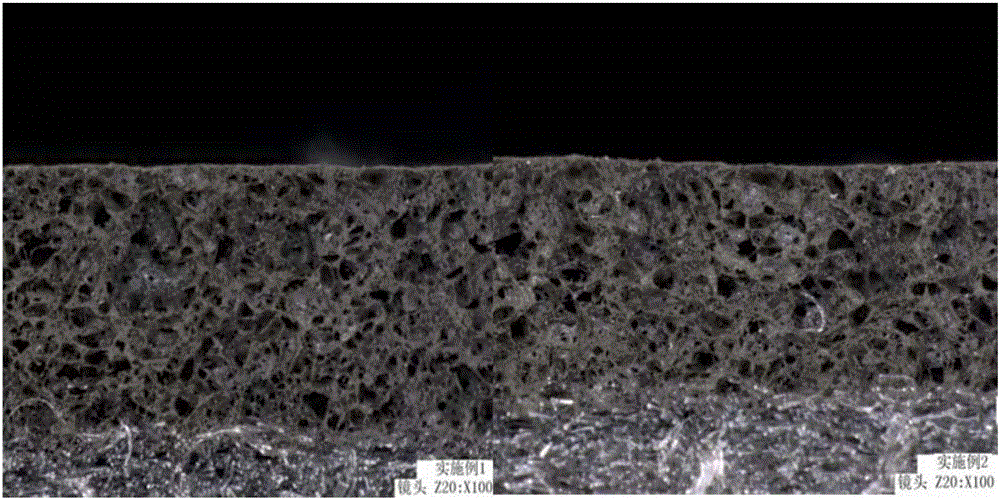

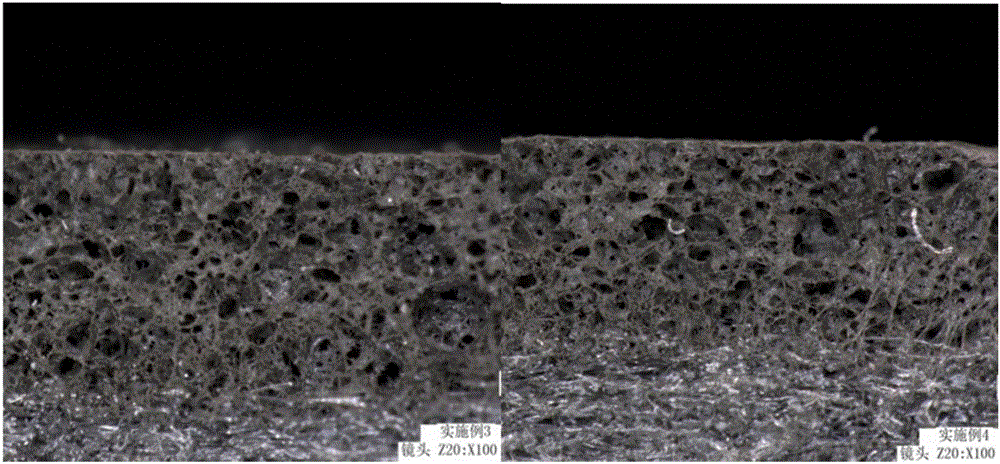

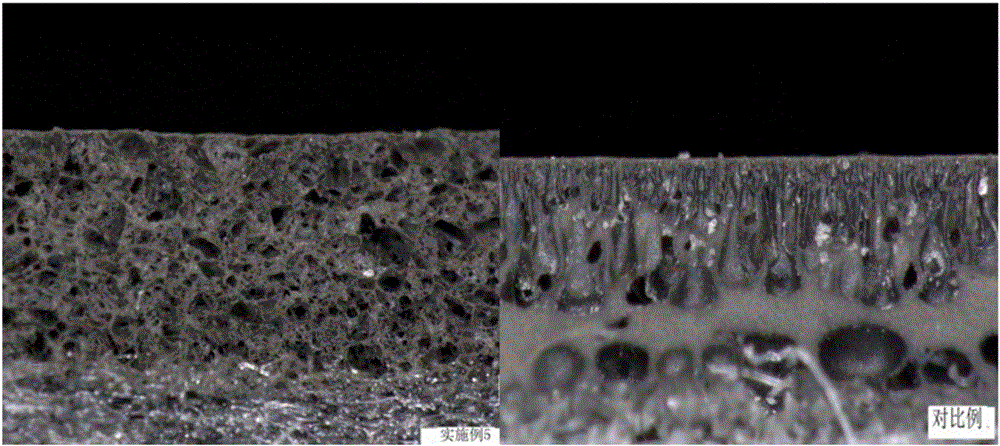

A wet-process resin and protein technology, which is applied in textiles and papermaking, coatings, polyurea/polyurethane coatings, etc., can solve the problems of low cell density, no hand feeling of synthetic leather, and insufficient natural leather resources, and achieve fine creases. , Sponge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1. Formula

[0029]

[0030] 2. Preparation method

[0031] 100kg of polyethylene adipate-1,4-butylene glycol ester diol (number-average molecular weight 4000g / mol), 50kg of polytetrahydrofuran ether diol (number-average molecular weight 2000g / mol) and double-terminal hydroxyl Polyether modified silicone oil (number average molecular weight 2000) 10kg, methylene diphenylmethane-4, 4-diisocyanate (MDI) 13.1kg and N, N-dimethylformamide 260kg carry out prepolymerization reaction, and reaction temperature is controlled at 75~85℃, after reacting for 2~3 hours, when the viscosity of the reaction liquid reaches 10~20Pa·s / 50℃, put 11.81kg of ethylene glycol and 48.26kg of diphenylmethane-4,4‵-diisocyanate into the reaction kettle Carry out chain extension reaction with N, N-dimethylformamide 1892kg, control the reaction temperature at 60-70°C, and react until the viscosity of the reaction liquid reaches 50°C, at 5-10Pa·s, add 597kg of polyvinyl alcohol 0388 powder, polyvin...

Embodiment 2

[0033] 1. Formula

[0034]

[0035] 2. Preparation method

[0036] In the reactor, drop into polyethylene adipate diol (number-average molecular weight 3000g / mol) 188kg, double-end hydroxyl polyether modified silicone oil (number-average molecular weight 3000g / mol) 10kg, diphenylmethane-4, 16.11kg of 4‵-diisocyanate (MDI) and 143kg of N,N-dimethylformamide were prepolymerized, and the reaction temperature was controlled at 75-85°C. After 2-3 hours of reaction, the viscosity of the reaction liquid reached 130-150Pa·s At / 50°C, put 18.25kg of ethylene glycol, 74kg of diphenylmethane-4,4‵-diisocyanate and 1305kg of N,N-dimethylformamide into the reaction kettle for chain extension reaction, and control the reaction temperature at 50~ 60°C, react until the viscosity of the reaction liquid reaches 50°C, at 20-30Pa·s, add 207kg of polyvinyl alcohol 0588 powder, 103.5kg of polyvinyl alcohol 2488 powder, and 4kg of polyamide wax for blending reaction, and react for 4-6 hours. Whe...

Embodiment 3

[0038] 1. Formula

[0039]

[0040]

[0041] 2. Preparation method

[0042]Put 180kg of polytetrahydrofuran ether diol (number average molecular weight 3000g / mol), 18kg of double-terminated hydroxyl polyether modified silicone oil (number average molecular weight 2000g / mol) and diphenylmethane-4,4-diisocyanate into the reaction kettle (MDI) 16.6kg and N,N-dimethylformamide 198kg for prepolymerization reaction, the reaction temperature is controlled at 75-85°C, after 2-3 hours of reaction, when the viscosity of the reaction liquid reaches 50-70Pa·s / 50°C, Put 14.55kg of ethylene glycol, 59.3kg of diphenylmethane-4,4‵-diisocyanate and 2195kg of N,N-dimethylformamide into the reaction kettle for chain extension reaction, and control the reaction temperature at 70-80°C. When the viscosity of the reaction liquid reaches 50°C, at 8-12 Pa·s, add 296.5 kg of polyvinyl alcohol 1788 powder, 296.5 kg of polyvinyl alcohol 0386 powder, and 8 kg of polyamide wax for blending reaction,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com