Hole lotus fiber spinning components

A spinning assembly and lotus-shaped technology, which is applied in the field of hole-shaped fiber spinning assemblies, can solve problems such as instability, and achieve the effects of good formability, high coverage and comfortable wearing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

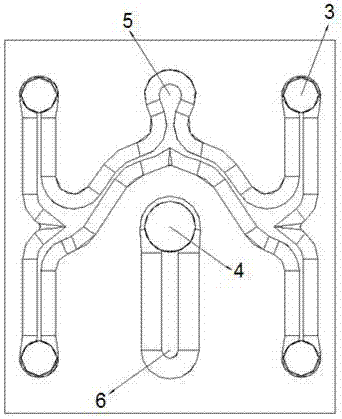

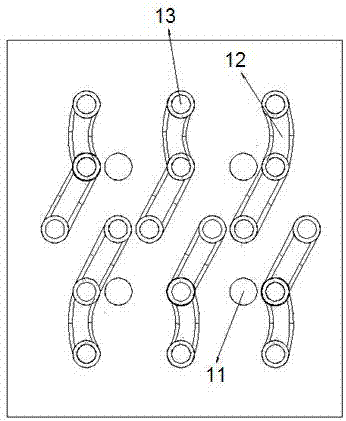

[0038] The making of A component / B component two kinds of macromolecular polymer lotus-shaped fibers: A component, B component are by the ratio of 40 / 60, arrive at the device of the present invention by melt extruding respectively in screw extruder, in The device of the present invention passes through respective independent flow channels, and finally converges at the exit of the spinneret to form a fiber of multiple B component filaments surrounded by A component. Through post-processing reduction treatment, lotus root-shaped fibers are finally formed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com