Waterborne polyurethane composite material for shoes and preparation method thereof

A water-based polyurethane and composite material technology, applied in the field of polyurethane materials, can solve the problems that the formula cannot meet the customer's peeling, folding resistance, hydrolysis resistance, the formulation process cannot meet the customer's use requirements, and the customer's requirements cannot be met, and the surface can not be satisfied. Slippery requirements, soft and comfortable bonding and shape, prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051]A water-based polyurethane composite material for shoes, comprising an epidermis layer, an intermediate layer, an adhesive layer and a base fabric layer that are sequentially attached from the outside to the inside; the epidermis layer is made of water-based surface layer resin slurry; the intermediate layer is made of The water-based intermediate layer is made of resin slurry; the adhesive layer is made of solvent-free resin slurry;

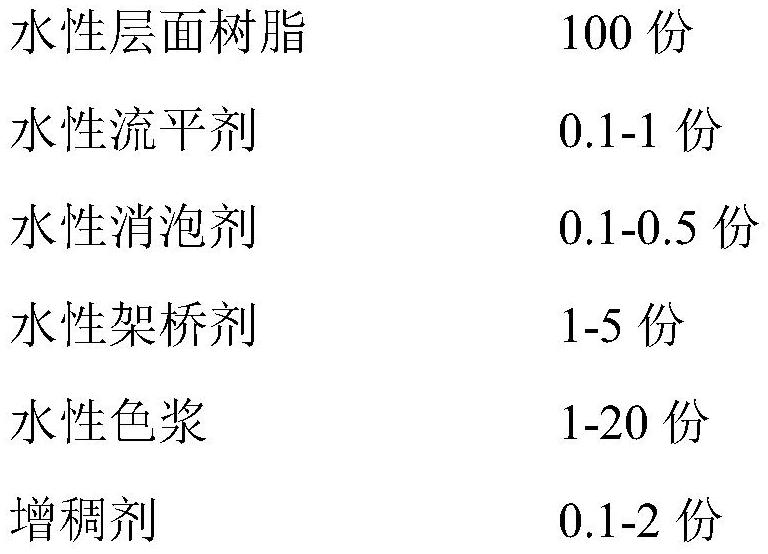

[0052] The water-based surface layer resin slurry is made of the following components in parts by weight:

[0053]

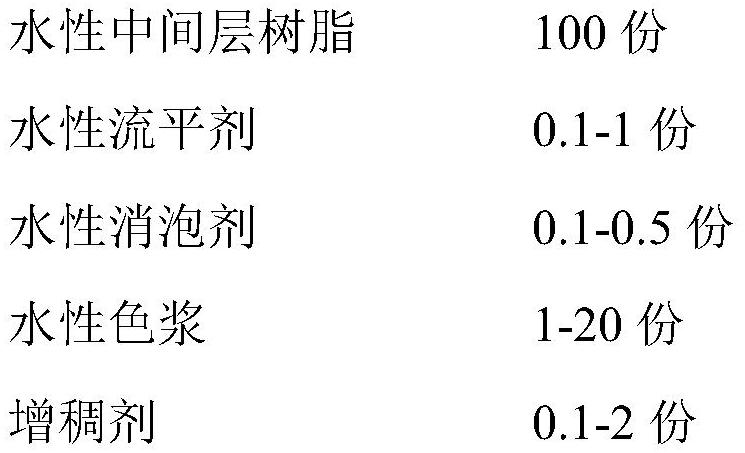

[0054] The water-based intermediate layer resin slurry is made of the following components in parts by weight:

[0055]

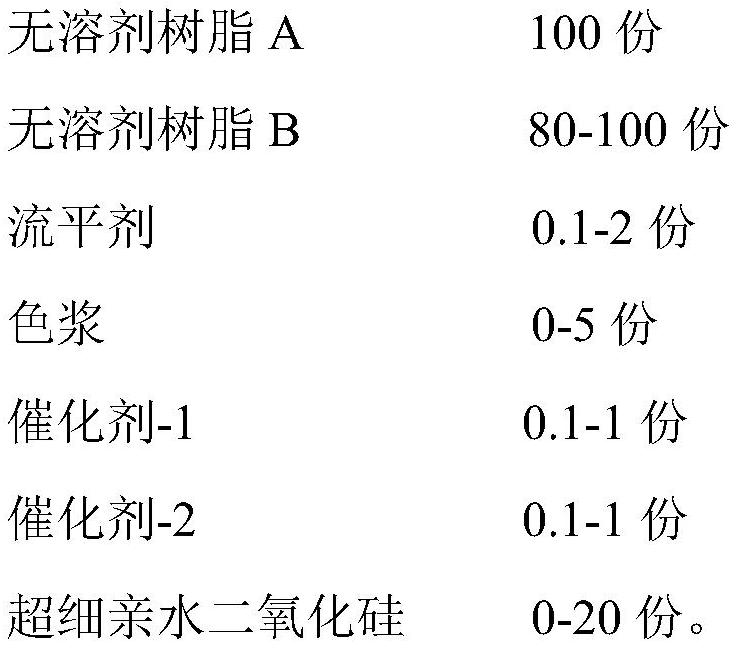

[0056] The solvent-free resin slurry is made of the following components in parts by weight:

[0057]

[0058] The viscosity of the water-based surface layer resin slurry is 5500CPS / 25°C, and the coating weight is 180g / m; the viscosity of the water-based intermediate layer resin slurry is 4500CP...

Embodiment 2

[0068] A water-based polyurethane composite material for shoes, comprising an epidermis layer, an intermediate layer, an adhesive layer and a base fabric layer that are sequentially attached from the outside to the inside; the epidermis layer is made of water-based surface layer resin slurry; the intermediate layer is made of The water-based intermediate layer is made of resin slurry; the adhesive layer is made of solvent-free resin slurry;

[0069] The water-based surface layer resin slurry is made of the following components in parts by weight:

[0070]

[0071] The water-based intermediate layer resin slurry is made of the following components in parts by weight:

[0072]

[0073] The solvent-free resin slurry is made of the following components in parts by weight:

[0074]

[0075] The viscosity of the water-based surface layer resin slurry is 5500CPS / 25°C, and the coating weight is 180g / m; the viscosity of the water-based intermediate layer resin slurry is 4500C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Modulus of elongation | aaaaa | aaaaa |

| Modulus of elongation | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com