Suspended labyrinth sleeve structure

A labyrinth sleeve and suspension technology, which is applied in the field of sleeve structure and suspension labyrinth sleeve structure, can solve the problems of short maintenance period of valve internal parts, leakage of upper gasket, damage of sealing surface, etc., and achieves obvious economic advantages , prolong the service life and the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

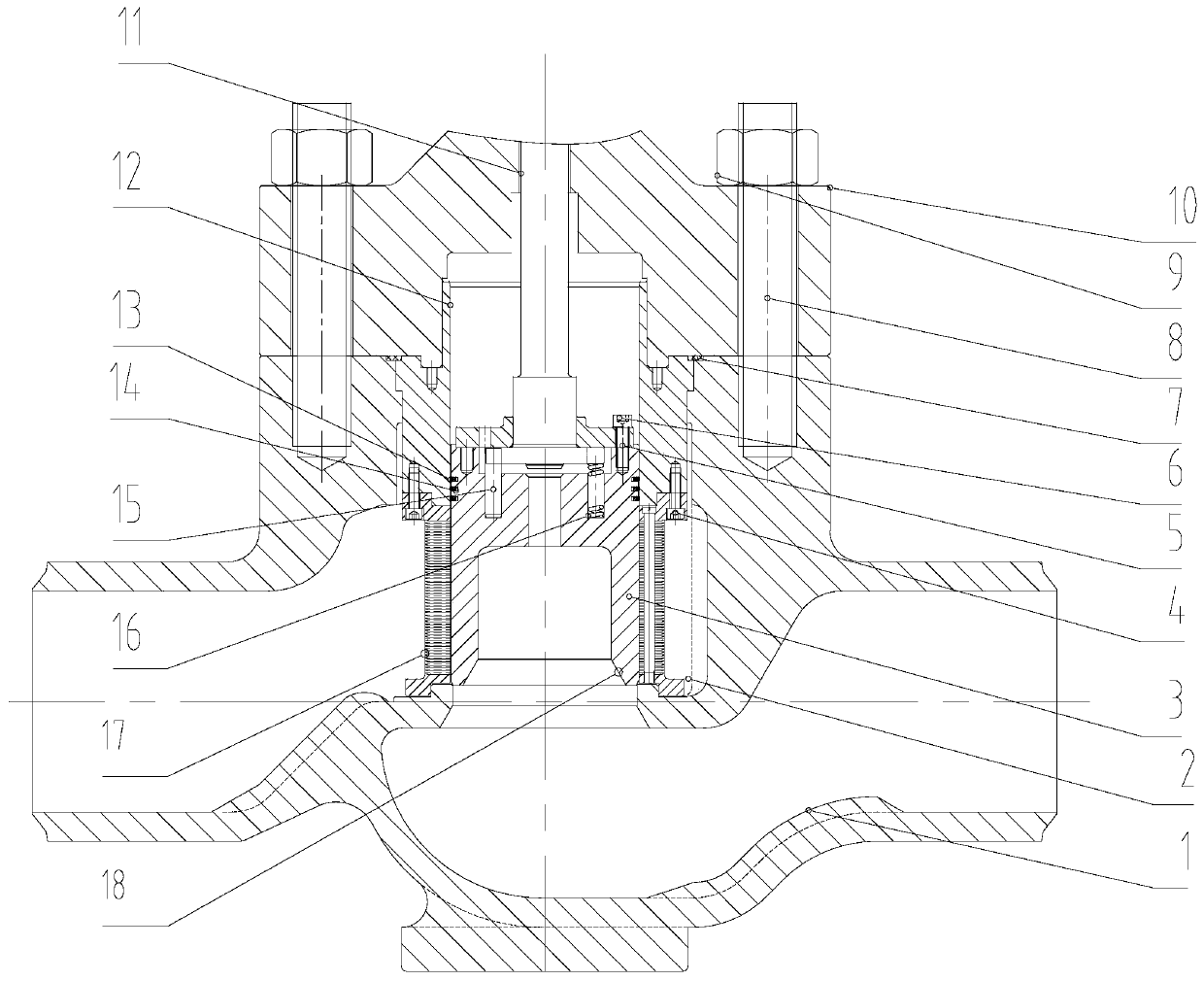

[0019] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0020] Such as figure 1 As shown: the present invention mainly includes a valve body 1, a gasket 7, a stud 8, a nut 9, an upper cover 10, a sleeve assembly 17 and a valve core assembly 18, and the valve body 1 is distributed with an inlet channel and an outlet The flow channels are respectively placed at both ends of the valve body 1, and the flow direction adopts the flow direction of high in and bottom out; the sleeve assembly 17 is installed on the boss of the upper chamber of the valve body 1, and the sleeve assembly 17 is constrained on the valve body. Movement in the radial direction inside the body 1; a spool assembly 18 is set in the sleeve assembly 17, and the spool assembly 18 can move linearly along the inner wall of the sleeve assembly 17; the spool assembly 18 moves in the sleeve assembly 17 , to realize the adjustment of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com