Vertical fluorine-lined pipeline chemical pump

A chemical pump and vertical technology, applied in the field of vertical fluorine-lined pipeline chemical pump, can solve the problems of complexity, easy cracking and corrosion, less specifications, etc., and achieve the effect of high degree of generalization, strong interchangeability, and convenient centering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

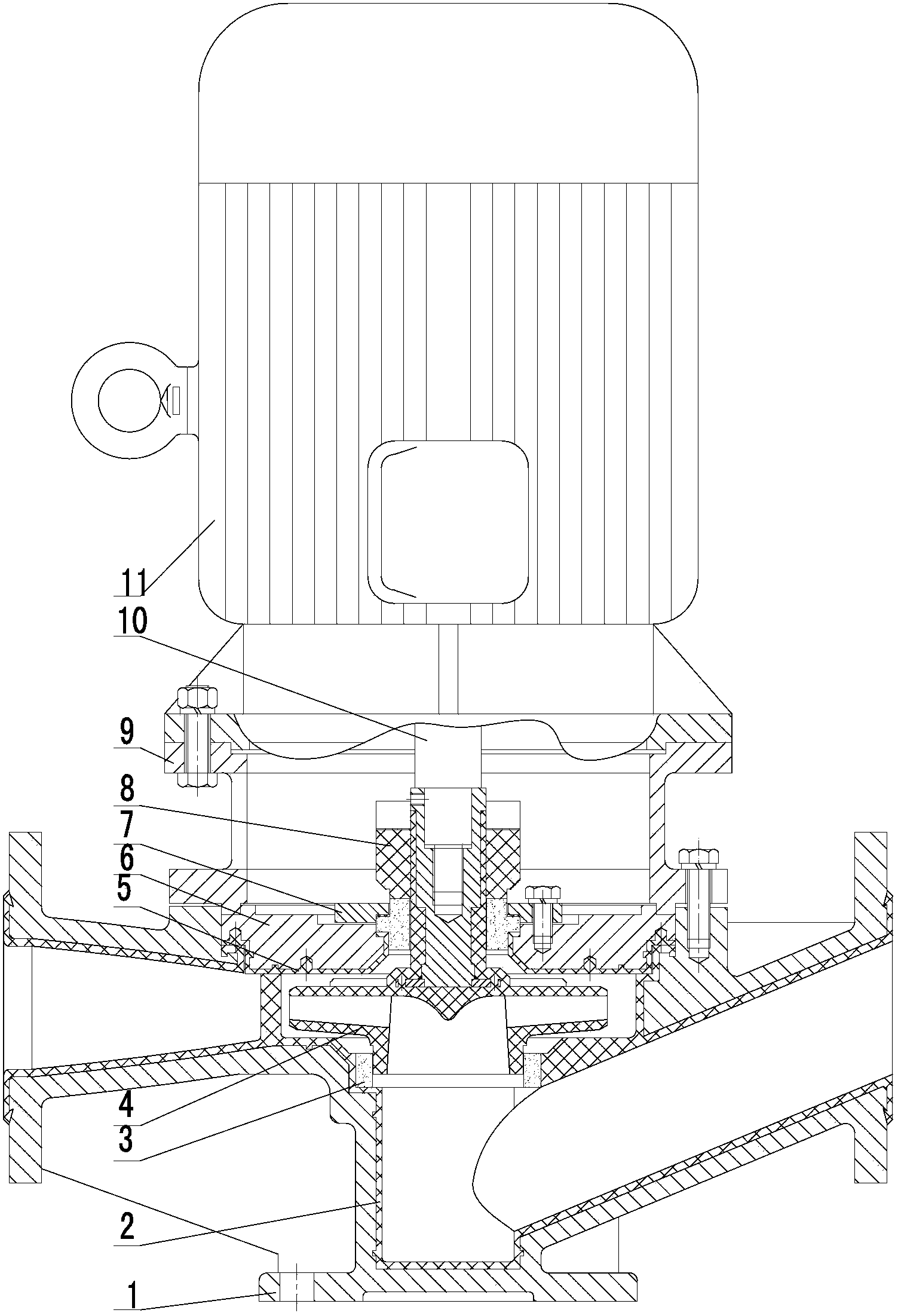

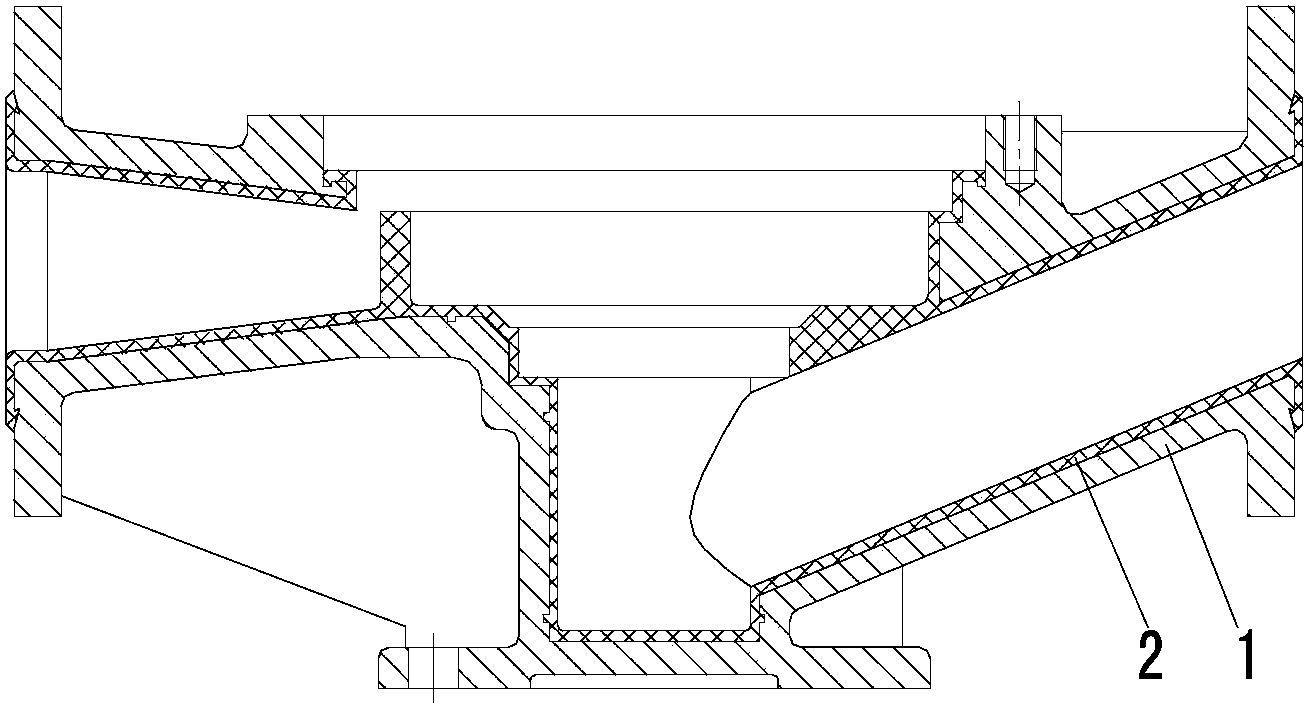

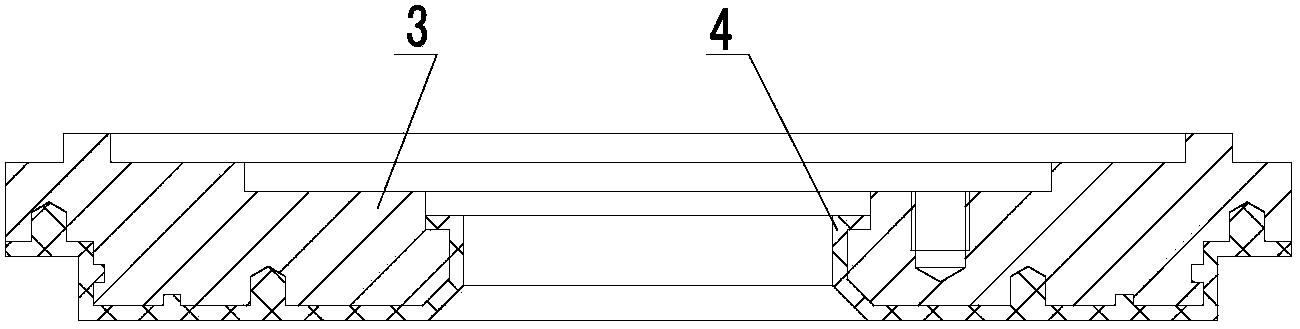

[0021] see figure 1 , with reference to figure 2 , image 3 , the vertical fluorine-lined pipeline chemical pump of the present invention includes a pump body 1, a pump body lining 2, a sealing ring 3, an impeller 4, a pump cover lining 5, a pump cover 6, a machine cover 7, a shaft seal 8, a coupling Frame 9, electric pump shaft 10, motor 11. The connecting frame 9 is installed on the pump body 1, and the motor 11 is installed on the connecting frame 9; parts such as the connecting frame have strong interchangeability and a high degree of generalization.

[0022] The inner liner 2 of the pump body, the inner liner 5 of the pump cover and the impeller 4 in the present invention are all formed by one-time molding of pure F46 material.

[0023] The vertical fluorine-lined pipeline chemical pump of the present invention adopts a vertical installation design, the motor 11 is on the top, the pump body 1 is on the bottom, and the pump body is provided with mounting feet. The inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com