Proton exchange membrane and preparation method thereof

A technology for proton exchange membranes and membrane components, which is applied in the manufacture of final products, sustainable manufacturing/processing, solid electrolyte fuel cells, etc., and can solve the problems of inability to obtain continuous and uniform membranes, poor mechanical properties, and no practical value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] (1) Preparation of mixed poly(p-phenylenebenzobisoxazole) and polyphosphoric acid (PBO / PPA) slurry

[0056] Add 114.90g of 4,6-diaminoresorcinol hydrochloride (DAR), 917.8g of P 2 o 5 Polyphosphoric acid (PPA) with a concentration of 80wt%, 89.55g of terephthalic acid (PTA) with a particle size of 5 microns and 316.50g of P 2 o 5 , Seal the reaction kettle, start the agitator, the stirring direction is the same as the helical direction of the bolt belt, and the rotation speed is 80rpm.

[0057] Raise the temperature of the reaction materials in the reaction kettle to 40°C and keep for 1 hour to make the materials mix initially, then slowly raise the temperature to 65°C and keep for 1 hour. Feed dry high-purity nitrogen gas into the reactor, so that the pressure in the reactor reaches 0.5 MPa, and at the same time raise the temperature to 110°C, keep it for 15 hours, open the pressure relief valve, and remove the pressure from the reactor.

[0058] Then heat up the r...

Embodiment 2

[0068] 1) Preparation of mixed poly(p-phenylenebenzobisoxazole) and polyphosphoric acid (PBO / PPA) slurry

[0069] Add 114.9g of 4,6-diaminoresorcinol hydrochloride (DAR), 920.3g of P 2 o 5 Polyphosphoric acid (PPA) at a concentration of 80 wt%, 152.6g of 2,5-dihydroxyterephthalic acid with a particle size of 5 microns and 326.40g of P 2 o 5 , Seal the reaction kettle, start the agitator, the stirring direction is the same as the helical direction of the bolt belt, and the rotation speed is 80rpm.

[0070]Raise the temperature of the reaction materials in the reactor to 50°C and keep for 1 hour to make the materials mix initially, then slowly raise the temperature to 70°C and keep for 1 hour. Feed dry high-purity nitrogen into the reactor to make the pressure in the reactor reach 1.5MPa, and at the same time raise the temperature to 120°C, keep it for 6 hours, open the pressure relief valve, and remove the pressure from the reactor.

[0071] Then heat up the reaction materi...

Embodiment 3

[0082] (1) Preparation of mixed poly(p-phenylenebenzobisoxazole) and polyphosphoric acid (PBO / PPA) slurry

[0083] Add 114.90g of 4,6-diaminoresorcinol hydrochloride (DAR), 919.3g of P 2 o 5 Polyphosphoric acid (PPA) with a concentration of 80wt%, 109.43g terephthaloyl chloride with a particle size of 5 microns and 321.50gP 2 o 5 , Seal the reaction kettle, start the agitator, the stirring direction is the same as the helical direction of the bolt belt, and the rotation speed is 90rpm.

[0084] Raise the temperature of the reaction materials in the reaction kettle to 45°C and keep for 1 hour to make the materials mix initially, then slowly raise the temperature to 60°C and keep for 1 hour. Feed dry high-purity nitrogen into the reactor to make the pressure in the reactor reach 1.2MPa, and at the same time raise the temperature to 120°C, keep it for 15 hours, open the pressure relief valve, and remove the pressure from the reactor.

[0085] Then the reaction mass was heated...

PUM

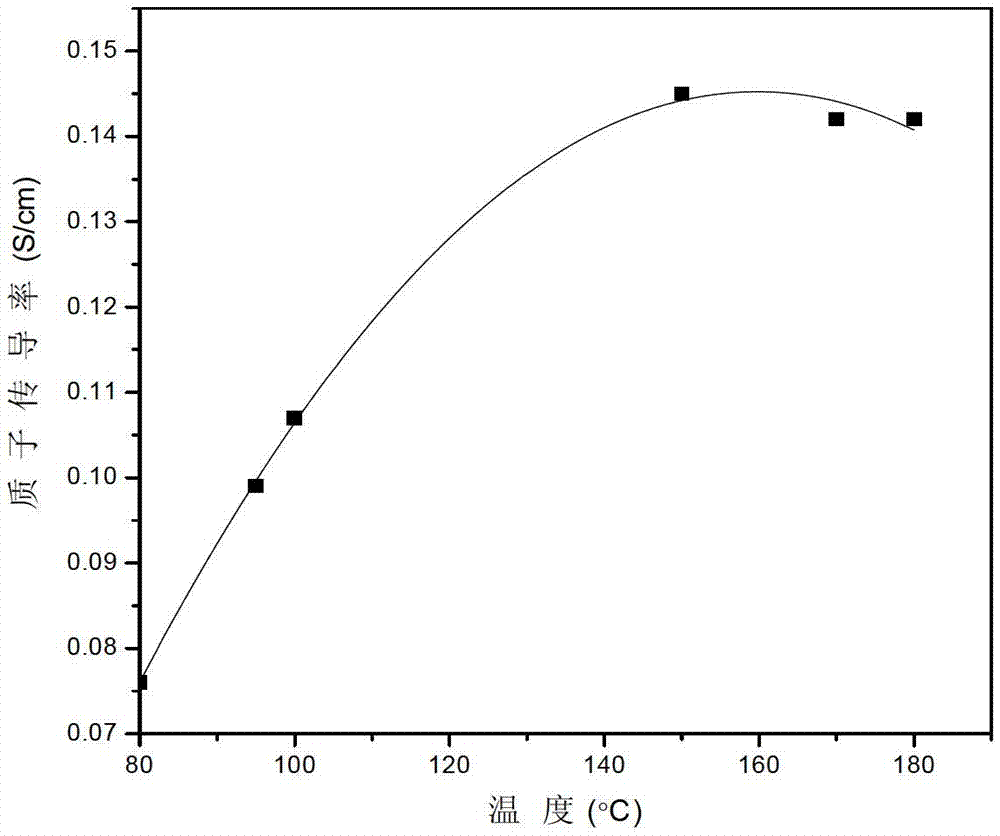

| Property | Measurement | Unit |

|---|---|---|

| ionic conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com