Numerically controlled machine knife tool on-line coping device

A technology for CNC machine tools and cutting tools, which is applied in the direction of grinding machine parts, surface-polished machine tools, manufacturing tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

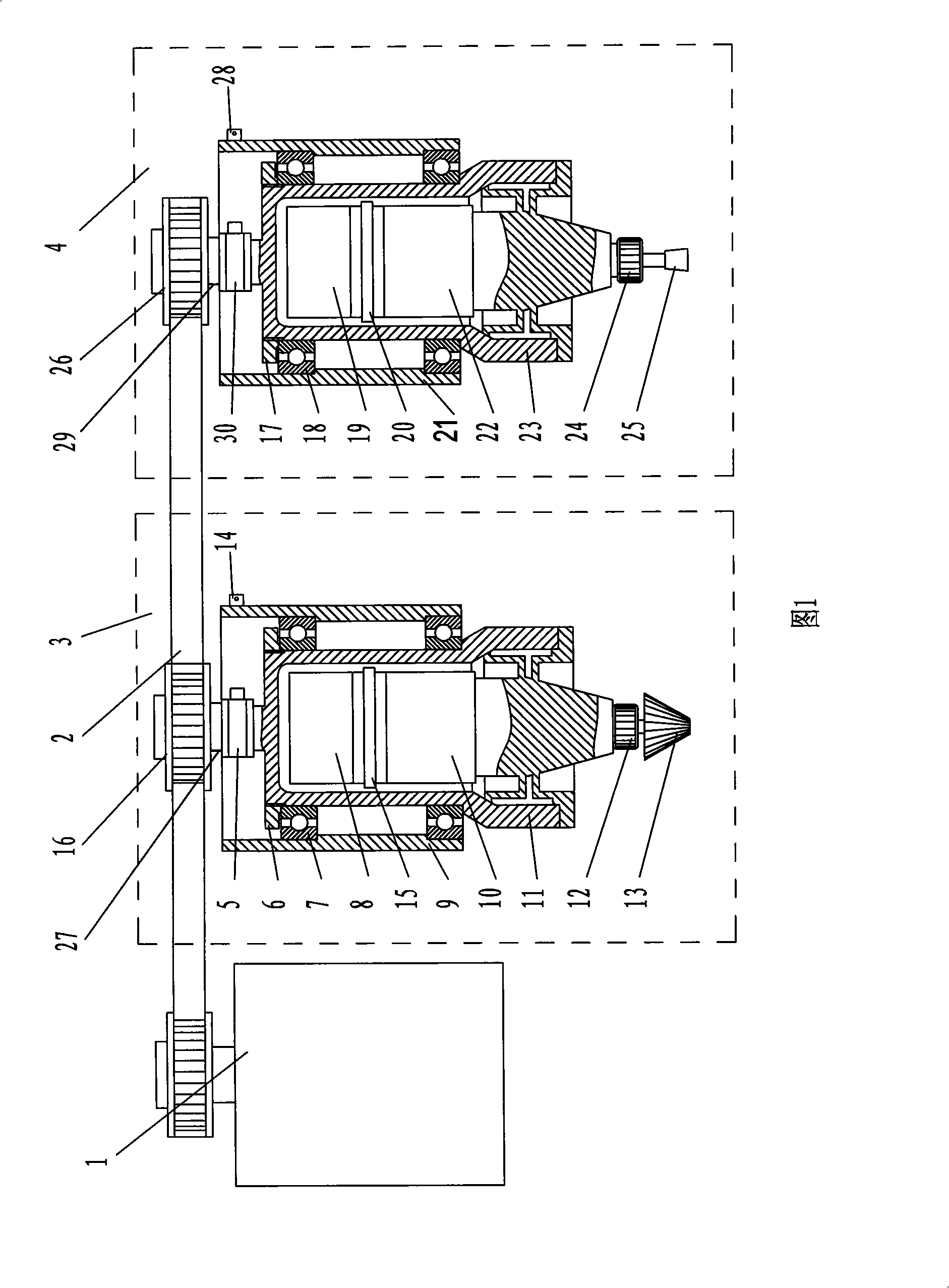

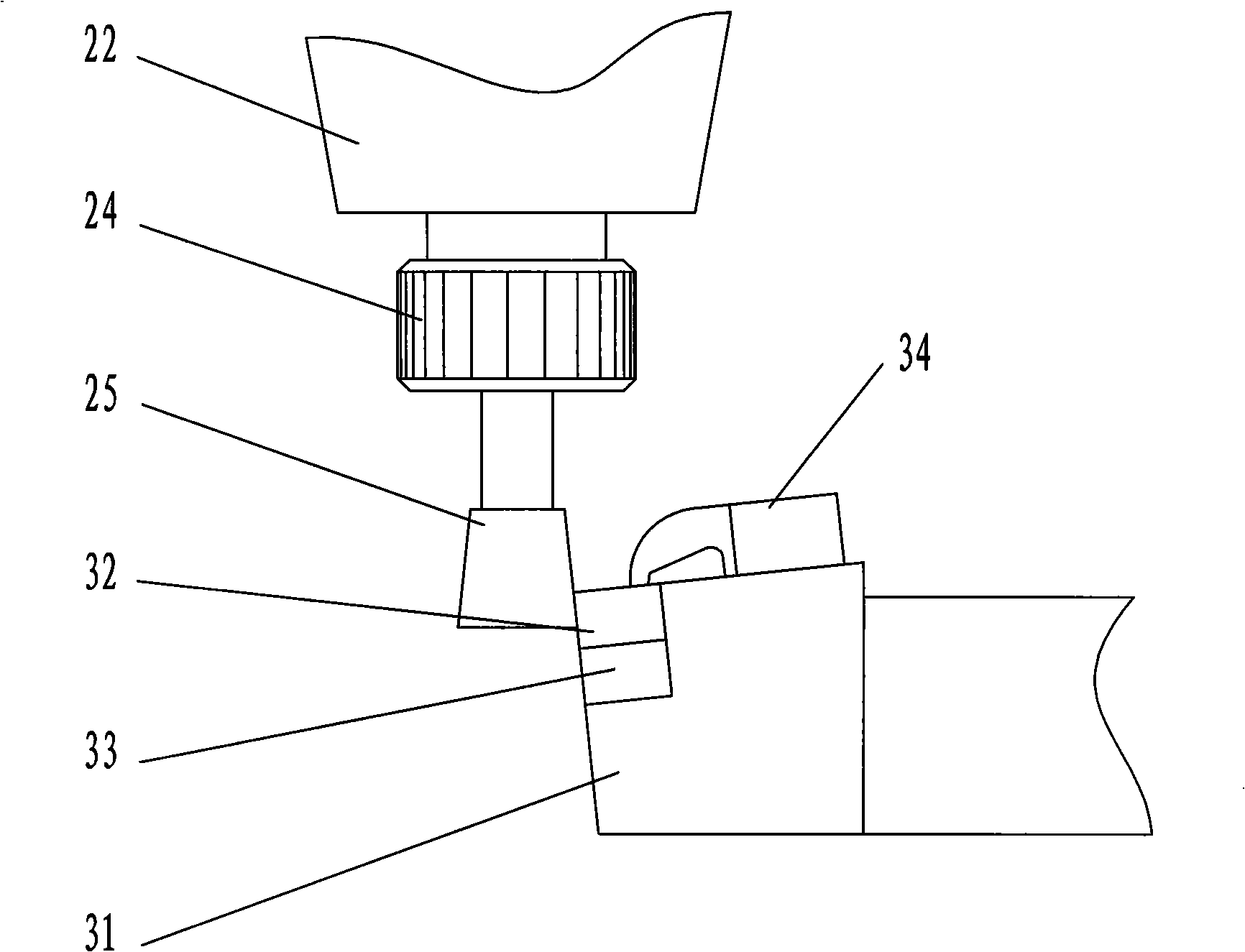

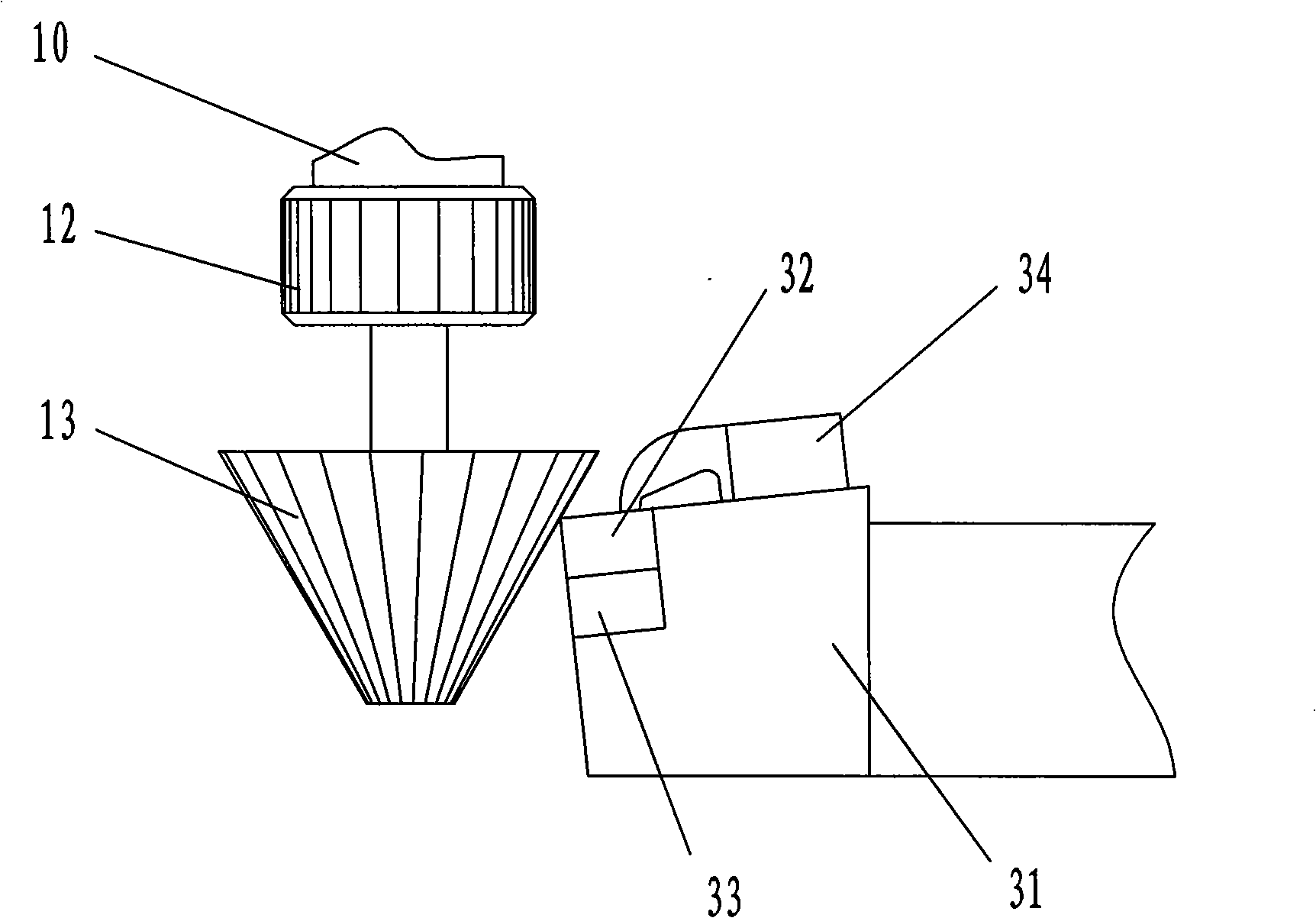

[0016] Provided by Fig. 1, the present invention includes motor, toothed belt, sharp edge rounding polishing head device 3 and ultrasonic vibration grinding head device 4, said sharp edge rounding polishing head device is, polishing head main shaft 27 one ends Polishing head toothed belt pulley 16 is housed on it, and the other end is equipped with polishing head 13 by polishing head collet 12, and polishing head horn 10 is arranged on the polishing head collet, and polishing head piezoelectric ceramic transducer 15 is contained in On the upper half shaft 8 of the polishing head, and connected together with the lower polishing head horn 10 through the thread on the upper half shaft 8, the polishing head shift lever and the polishing head piezoelectric ceramic transducer are installed in the polishing head housing 11 Inside, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com