Method for manufacturing ultra-long microwave high-frequency circuit board

A high-frequency circuit board and manufacturing method technology, which is applied in the manufacture of printed circuits, printed circuits, and removal of conductive materials by chemical/electrolytic methods, etc. production and other problems to achieve the effect of satisfying mass production, improving bonding force and reducing hole wall defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

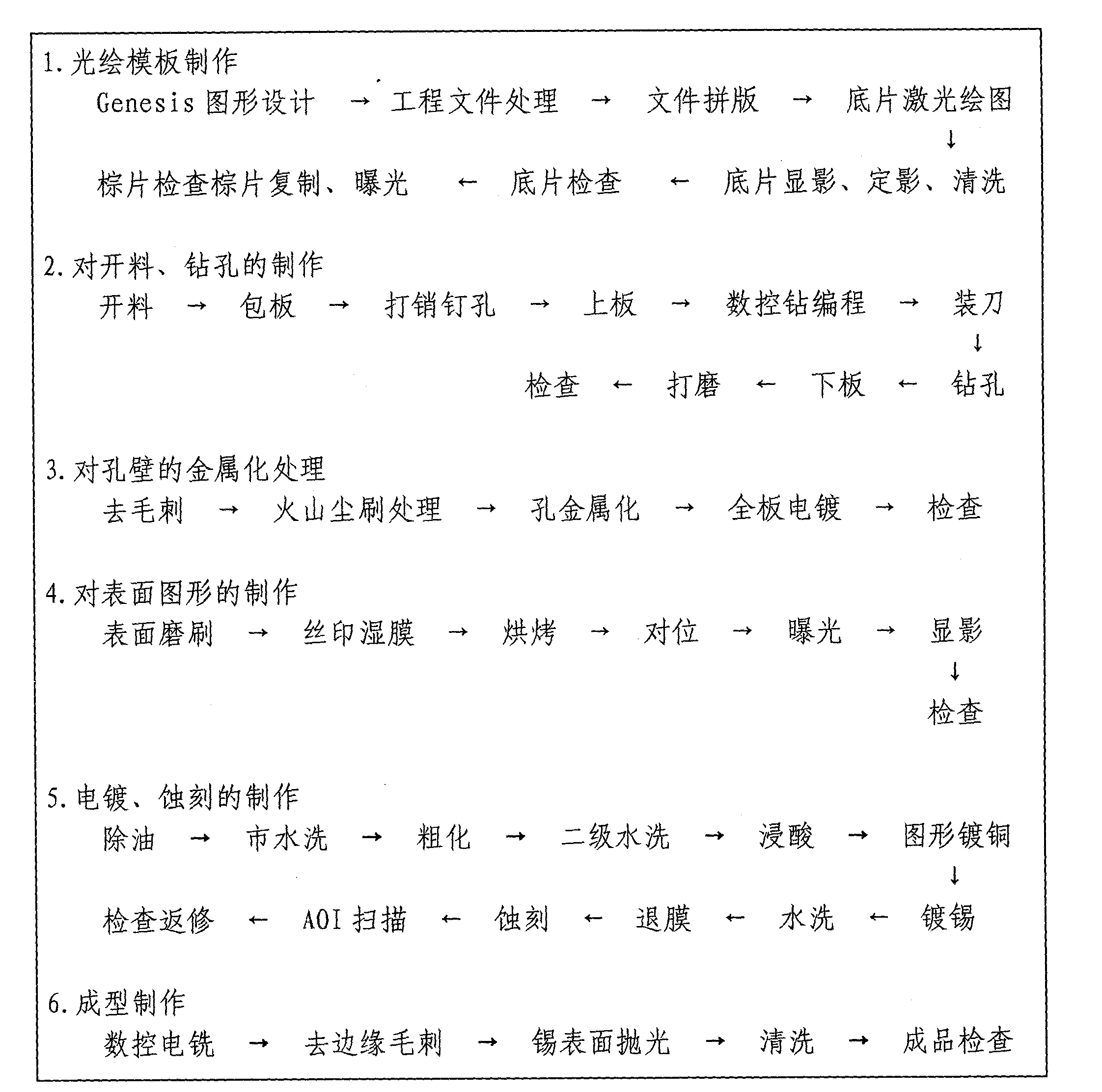

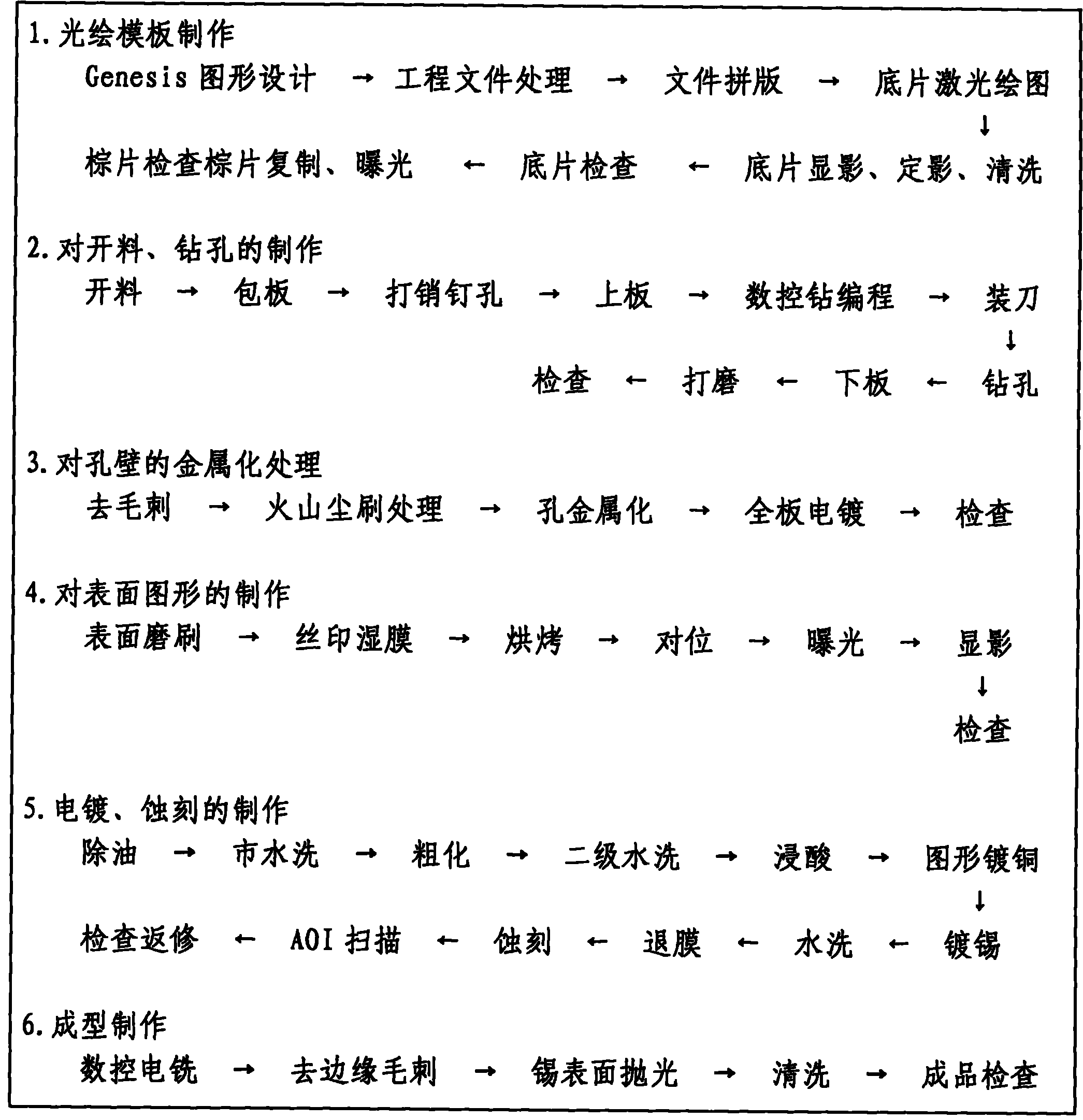

[0008] exist figure 1 Among them, the present invention is a method for manufacturing an ultra-long microwave high-frequency circuit board, which includes the following steps: Step 1, making a light-painting template: firstly, using GENESIS2000 to sequentially design the template and process the engineering documents according to the production process parameters, Make imposition of the processed files, and then use a high-precision laser photoplotter with a resolution of 10160dpi to photopaint the photopainted files into black negatives, develop, fix, clean and air-dry the photopainted negatives, and then use 100 ×100 microscope to inspect the negatives, and finally use the negatives as the master to copy the brown film with a 3KW exposure machine; Step 2, the production of material cutting and drilling: first use the electric shearing machine to cut out the required super-length according to the size requirements Microwave high-frequency copper-clad laminate, and then wrap t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com