Method for ultrasonic-assisted corrosion of middle-high voltage anode aluminum foil

An anode aluminum foil and ultrasonic technology, which is applied to circuits, capacitors, electrolytic capacitors, etc., can solve the problems that the specific capacity of aluminum foil cannot be effectively improved, the length of tunnel holes is uneven, etc., to achieve large-scale industrial production, low cost, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

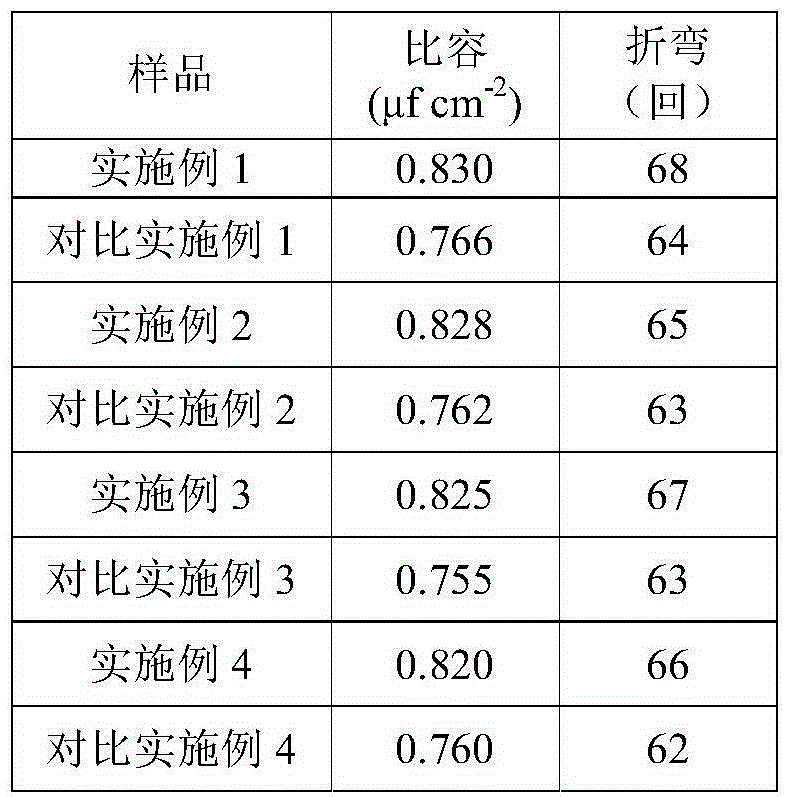

Examples

Embodiment 1

[0032] A method for ultrasonically assisted corrosion of medium and high voltage anode aluminum foil, comprising the following steps:

[0033] (1) Pre-treatment: soak the aluminum foil in a mixed solution containing 3% hydrochloric acid and 35% sulfuric acid by mass percentage for 120s at a temperature of 80°C;

[0034] (2) Ultrasonic-assisted primary porosity corrosion: put the pretreated aluminum foil in a porosity corrosion solution at a temperature of 75°C, and apply a current density of 600mAcm -2 The direct current is carried out porosity corrosion 80s, and supersonic treatment with 25KHz is assisted at the same time of porosity corrosion, and described porosity corrosion solution is the mixed solution that contains mass percent and is 3% hydrochloric acid and 35% sulfuric acid;

[0035] (3) Secondary hole expansion corrosion: put the aluminum foil with holes in it in a hole expansion corrosion solution at a temperature of 70°C, and apply a current density of 100mAcm -2...

Embodiment 2

[0039] A method for ultrasonically assisted corrosion of medium and high voltage anode aluminum foil, comprising the following steps:

[0040] (1) Pretreatment: soak the aluminum foil in a mixed solution containing 0.1% hydrochloric acid and 40% sulfuric acid by mass percentage at a temperature of 40°C for 30 seconds;

[0041] (2) Ultrasonic-assisted primary porosity corrosion: put the pretreated aluminum foil in a porosity corrosion solution at a temperature of 65°C, and apply a current density of 400mAcm -2 direct current for pore corrosion for 30s, assisted with 28KHz ultrasonic treatment while pore corrosion, the pore corrosion solution is a mixed solution containing 1% hydrochloric acid and 40% sulfuric acid in mass percentage;

[0042] (3) Secondary hole expansion corrosion: put the aluminum foil with holes in it in the hole expansion corrosion solution at a temperature of 65°C, and apply a current density of 50mAcm -2 The DC current is used for hole expansion corrosion...

Embodiment 3

[0046]A method for ultrasonically assisted corrosion of medium and high voltage anode aluminum foil, comprising the following steps:

[0047] (1) Pre-treatment: soak the aluminum foil in a mixed solution containing 10% hydrochloric acid and 10% sulfuric acid by mass percentage at 80°C for 180s;

[0048] (2) Ultrasonic-assisted primary porosity corrosion: put the pretreated aluminum foil in a porosity corrosion solution at a temperature of 80°C, and apply a current density of 1000mAcm -2 The direct current is carried out porosity corrosion 180s, and supersonic treatment with 35KHz is assisted at the same time of porosity corrosion, and described porosity corrosion liquid is the mixed solution that contains mass percent and is 10% hydrochloric acid and 20% sulfuric acid;

[0049] (3) Secondary hole expansion corrosion: put the aluminum foil with holes in it in a hole expansion corrosion solution at a temperature of 85°C, and apply a current density of 200mAcm -2 The direct curr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com