Method for preparing alpha-beta composite semi-hydrated gypsum from phosphogypsum

A technology of hemihydrate gypsum and phosphogypsum, which is applied in the field of construction material preparation, can solve problems such as loose or compact atomic structure ordering, and achieve the effect of solving the bottleneck problem of sustainable development, low production cost, and simple production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

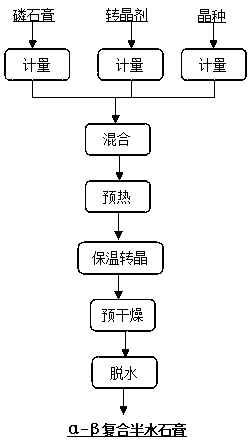

Image

Examples

Embodiment 1

[0029] The phosphogypsum is taken from the phosphogypsum storage yard. After analysis, the attached water content is 10%, and the pH value is 5.0. On a dry basis, take 200kg of this phosphogypsum, and weigh 0.2% of the dry basis mass of the phosphogypsum. 400g of aluminum, 4000g of seed crystals were weighed by 2% by mass, mixed evenly in a horizontal mixer twice, and transferred to the α-hemihydrate gypsum crystal conversion box.

[0030] (1) Preparation of α-β composite hemihydrate gypsum

[0031] Use steam to humidify subsaturated air with a humidity of 90% and a temperature of 80°C to heat up. When the temperature indicated by the crystal conversion box is > 60°C, use atmospheric pressure steam for heating, and maintain the temperature in the crystal conversion box at 100 ℃, humidity 95%, after 8 hours of heat preservation, then use 100 ℃ hot air for pre-drying and dehydration, when the attached water content of the material is less than 5%, transfer it to a drying oven fo...

Embodiment 2

[0035] Phosphogypsum is taken from the phosphoric acid production site. After analysis, its attached water content is 25%, and its pH value is 3.5. On a dry basis, take 200kg of this phosphogypsum, and weigh 0.5% of the dry basis of the phosphogypsum. 1000g, weigh 2000g of seed crystals according to 1% mass, mix them evenly in a horizontal mixer twice, and transfer them to the α-hemihydrate gypsum crystal conversion box.

[0036] (1) Preparation of α-β composite hemihydrate gypsum

[0037]Use steam to humidify subsaturated air with a humidity of 80% and a temperature of 100°C for heating and heating. When the temperature indicated by the crystal conversion box is > 60°C, use atmospheric pressure steam for heating, and maintain the temperature in the crystal conversion box at 85 ℃, humidity 85%, after 12 hours of heat preservation, then use 200 ℃ hot air for pre-drying and dehydration, when the attached water content of the material is less than 5%, transfer it to a drying oven...

Embodiment 3

[0041] Phosphogypsum is taken from the phosphoric acid production site. After analysis, its attached water content is 22%, and its pH value is 2.5. On a dry basis, take 200kg of this phosphogypsum, and weigh 0.3% of the phosphogypsum dry basis. 600g of aluminum, 3000g of seed crystals were weighed according to 1.5% by mass, mixed evenly in a horizontal mixer twice, and transferred to the α-hemihydrate gypsum crystal conversion box.

[0042] (1) Preparation of α-β composite hemihydrate gypsum

[0043] Use steam to humidify subsaturated air with a humidity of 85% and a temperature of 90°C for heating and heating. When the temperature indicated by the crystal conversion box is > 60°C, use atmospheric pressure steam for heating, and maintain the temperature in the crystal conversion box at 90°C ℃, humidity is 90%, after 10 hours of heat preservation, then use hot air at 150 ℃ for pre-drying and dehydration, when the attached water content of the material is less than 5%, transfer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com