Hight-pressure gypsum block and its continuously-forming machine

A technology for gypsum blocks and molding machines, which is applied to ceramic molding machines, manufacturing tools, etc. It can solve the problems of long production cycle and low strength, and achieve the effect of improving work efficiency and ensuring molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

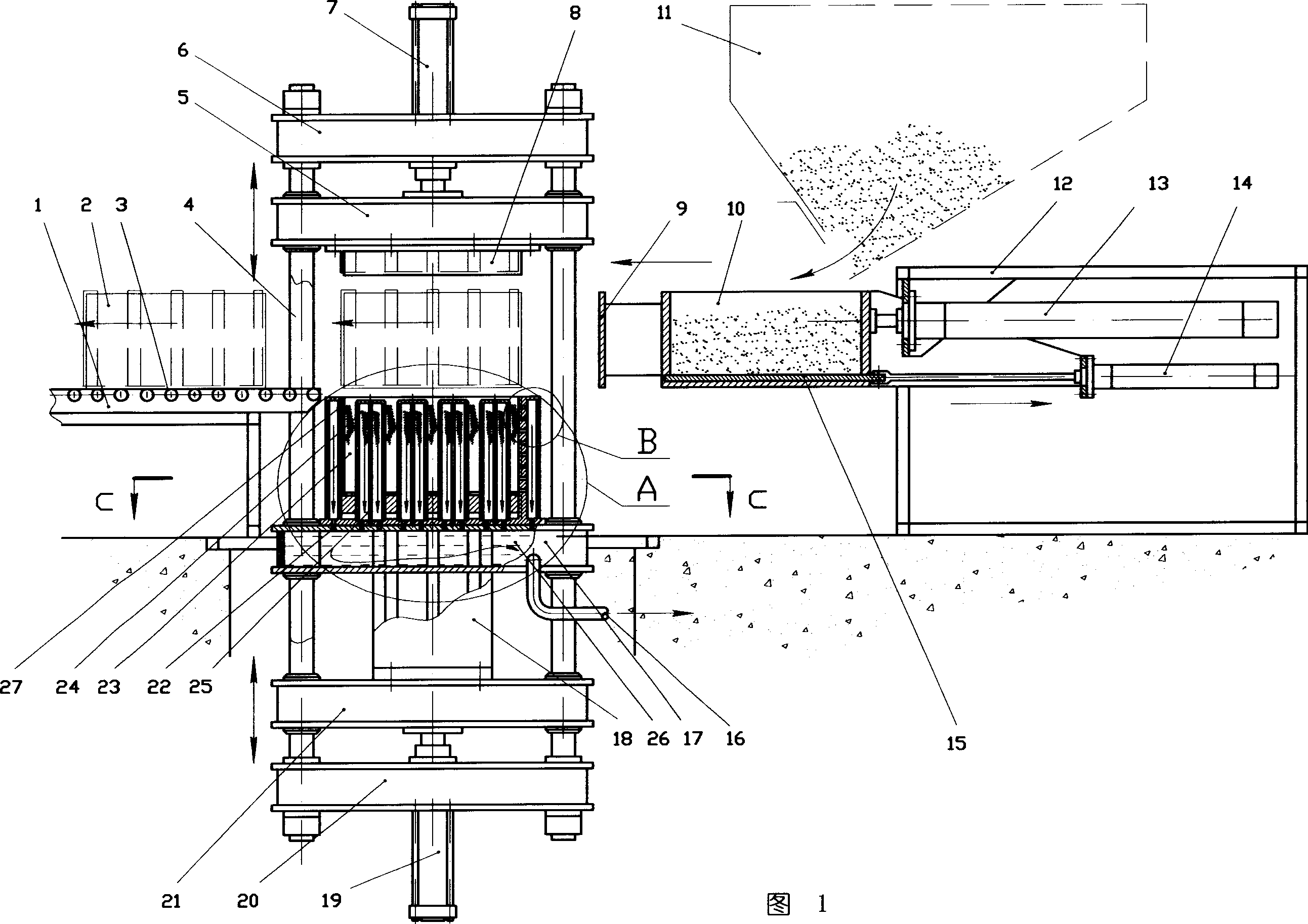

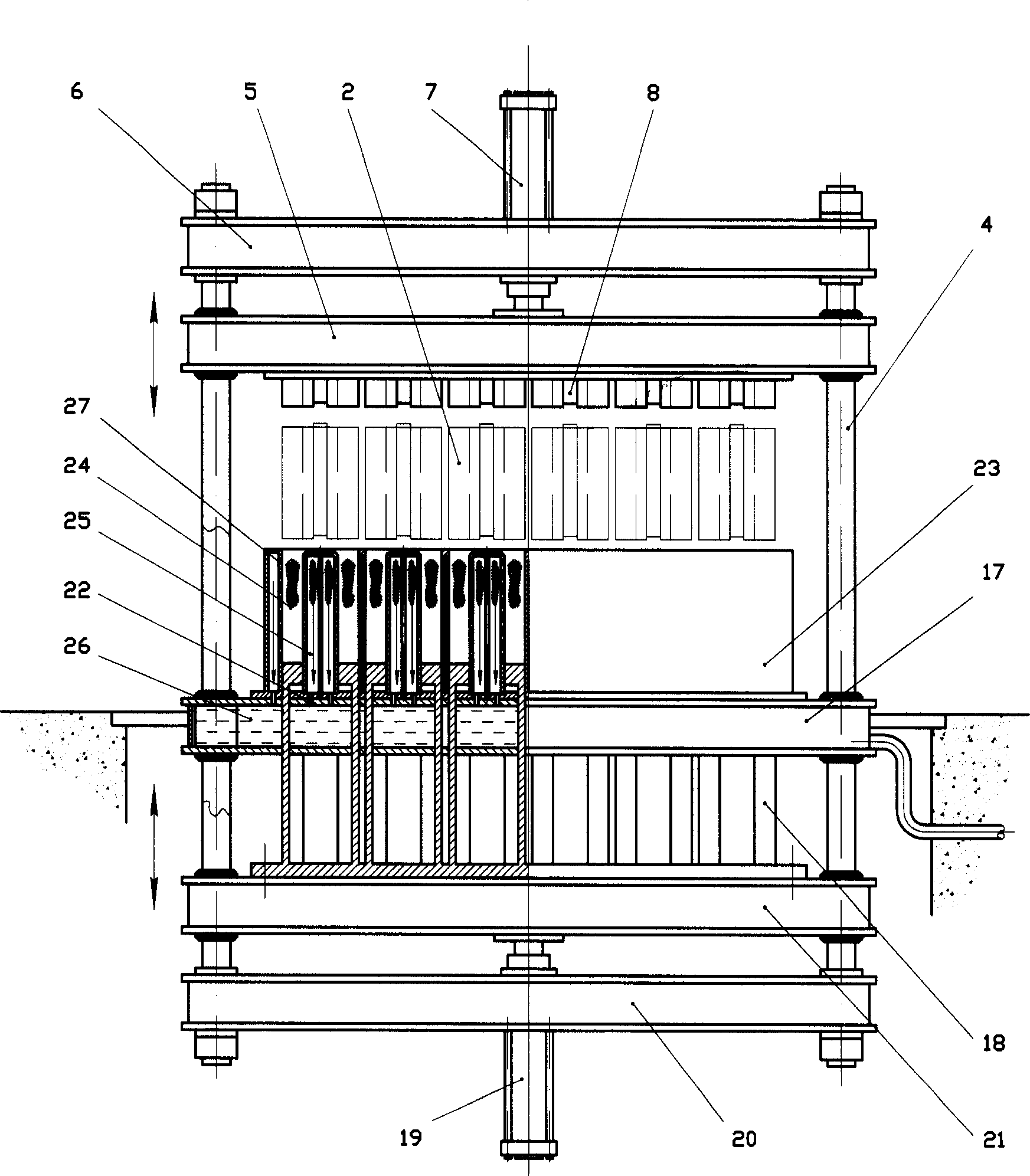

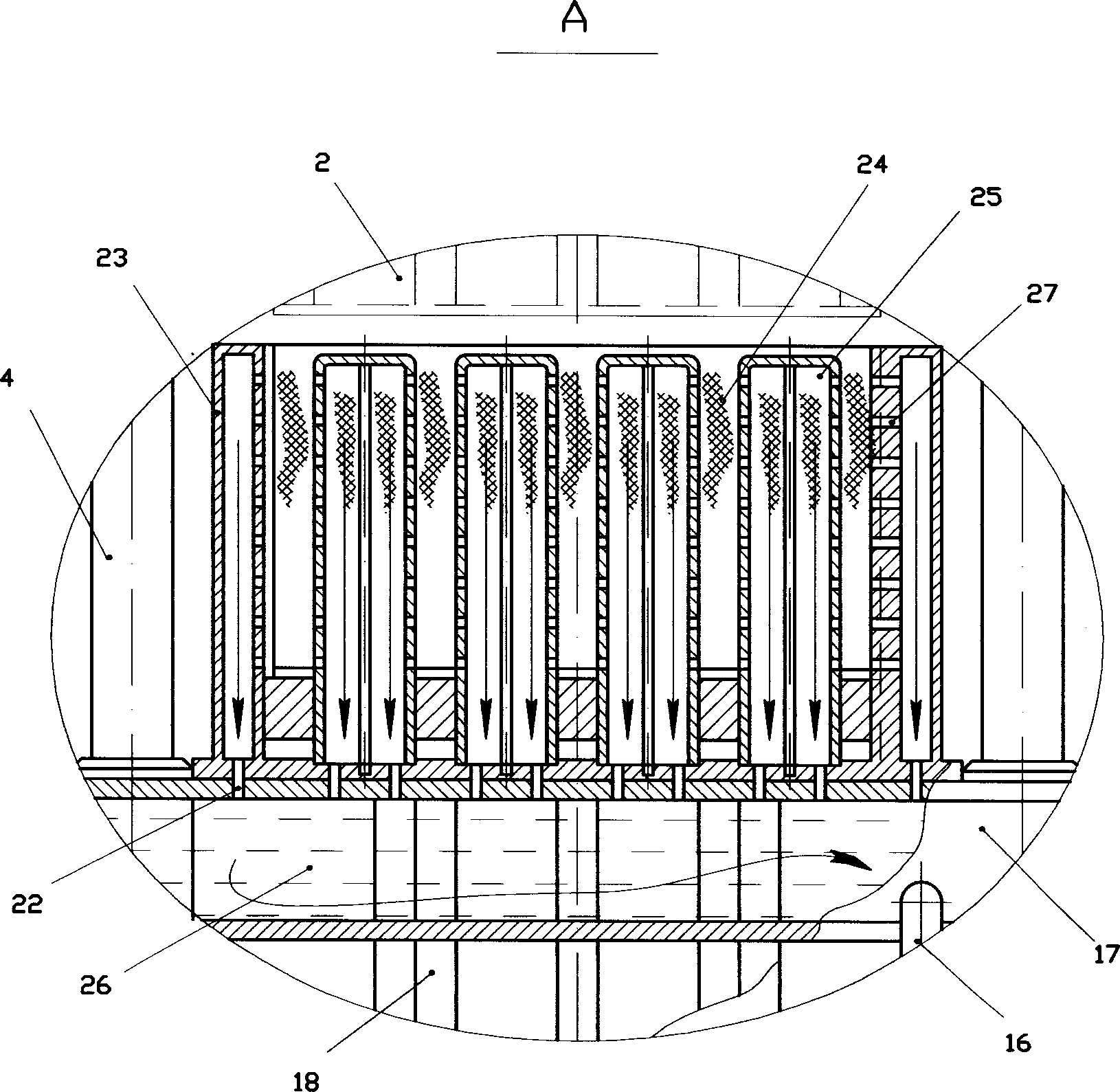

[0027] Figure 1 to Figure 5 The structural feature of the high-pressure gypsum block continuous molding machine shown in the figure is that the upper, middle and lower molds are used to jointly complete the pressurized water filtration molding of the fiber gypsum block products. The action sequence of the high-pressure gypsum block continuous molding machine is the distribution hopper 10. The hydraulic cylinder 13 pushes the mixed fiber gypsum slurry into the station of the middle mold 23. The hydraulic cylinder 14 moves to pull out the hopper door 15. After distributing, the hydraulic cylinder 13 drives the distributing hopper 10 to reset; the hydraulic cylinder 7 drives the upper mold 8 directions Press down to 8-10kg / cm 2 , the gypsum slurry in the middle mold is squeezed out of the water through the water filter micropores on the middle mold and the mold core under the action of pressure, and flows into the water tank 26 arranged below the middle mold to be discharged, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com