Process for producing high-strength alpha-gypsum from chemical gypsum by adopting dry method

A chemical gypsum and gypsum technology, which is applied in the technical field of chemical gypsum dry production of high-strength alpha gypsum, can solve problems such as unstable product performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

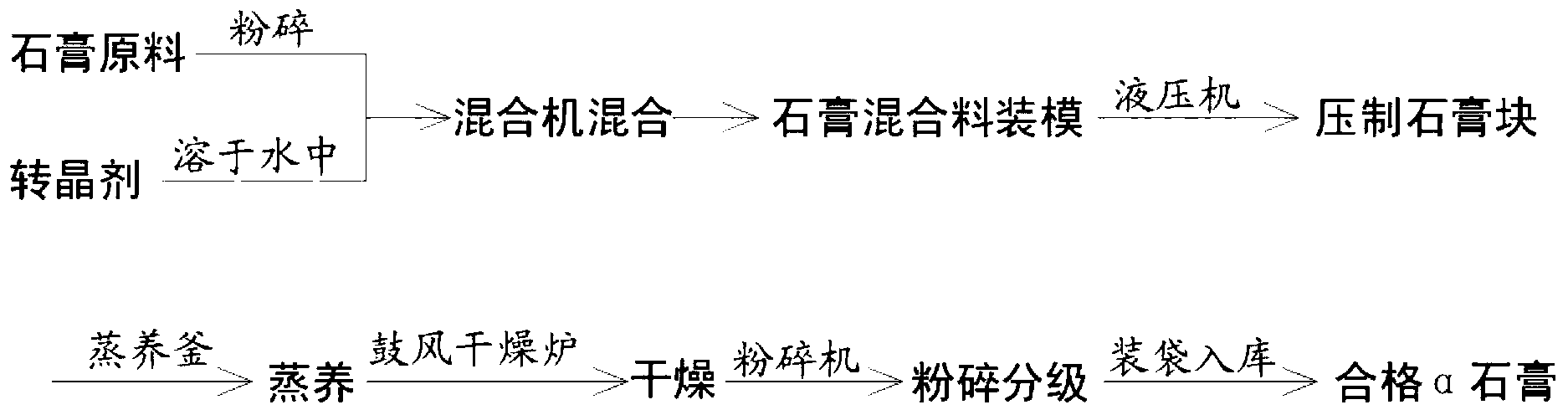

[0019] The process for producing high-strength α-gypsum by dry method of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0020] Specific implementation method one:

[0021] Pour 25 kg of chemical gypsum with a purity greater than 93.5% and a particle size of 100 mesh into a mixer and stir. The crystal-transforming agent sulfonate is a solution prepared by adding 1‰25g of gypsum to 2.5kg of water, and spray it on the surface of the gypsum stirred in the mixer. After mixing by the mixer for 20 minutes, take out the mixture from the mixer, pour it into the mold, place it on the platform of a 100-ton hydraulic forming press, turn on the hydraulic forming press, and align it at a speed of 1 mm / second. Pressurize, when the gypsum mixture is constantly under pressure, the water is squeezed out, the mixture is sheared and squeezed until the pressure is stable at 26MPa, and after holding the pressure for 5 minutes, release the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com