Conveyer-belt type block molding device for continuous producing gypsum block

A technology for gypsum blocks and conveyor belts, which is applied in the field of conveyor belt-type block mold machines, can solve the problems of high cost of equipment and molds, and the inability of continuous mass production of production equipment to achieve reduced production costs, good social benefits and economic benefits. benefit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

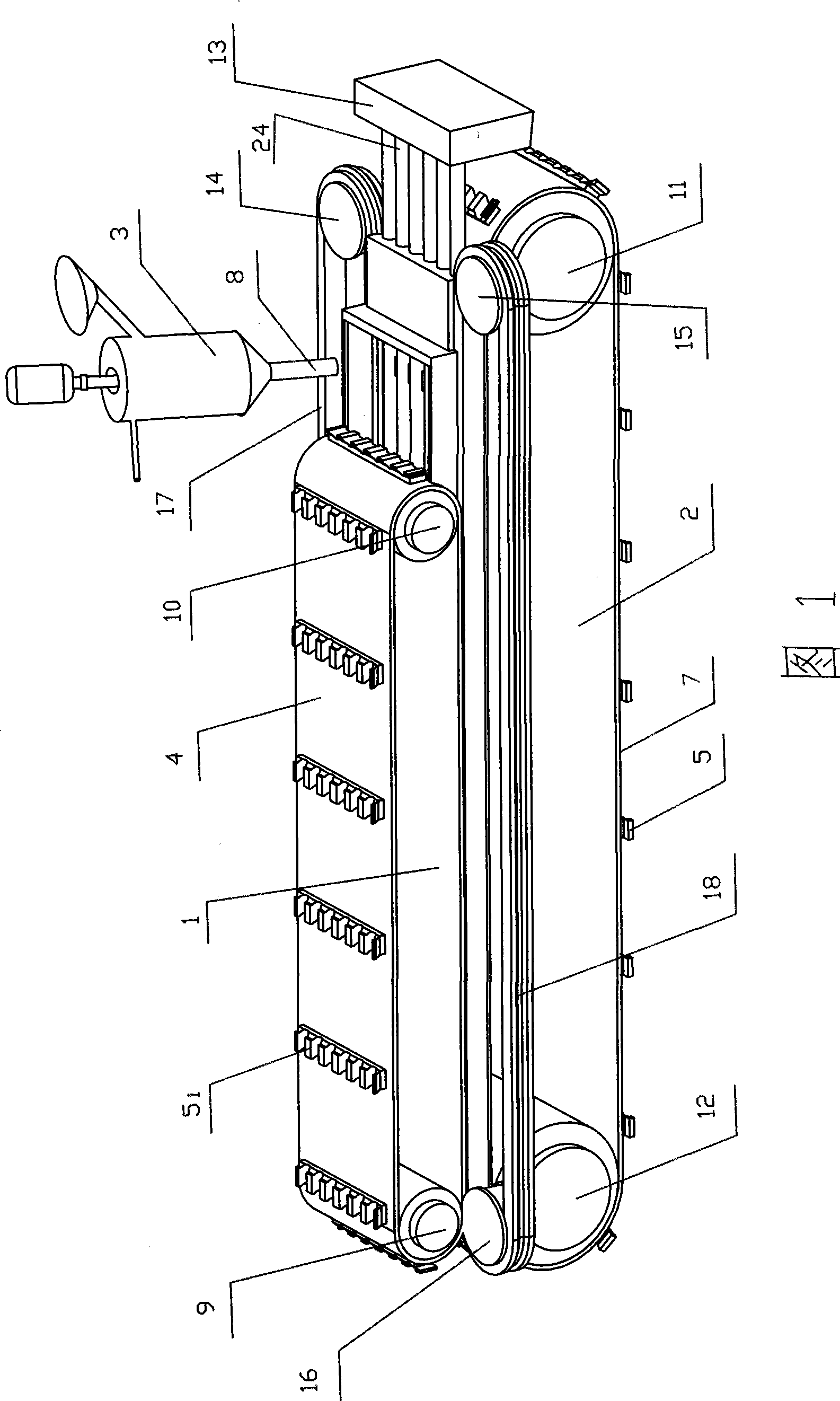

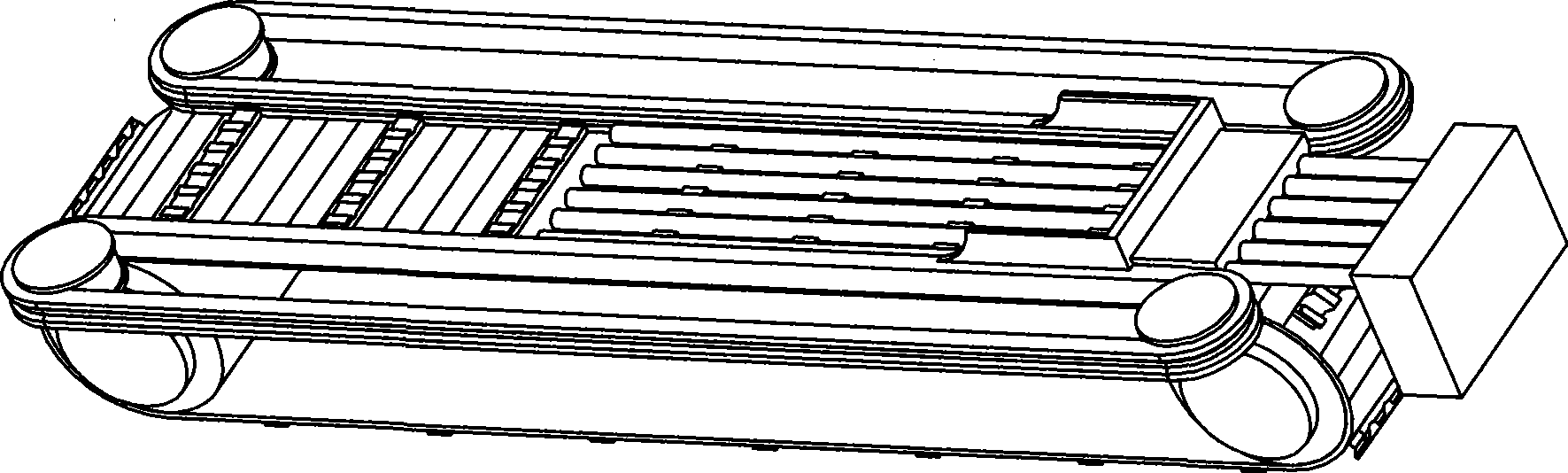

[0049] Embodiment 1: conveyor belt type block mold machine 2 produces A type ( Figure 4 ) gypsum block as an example

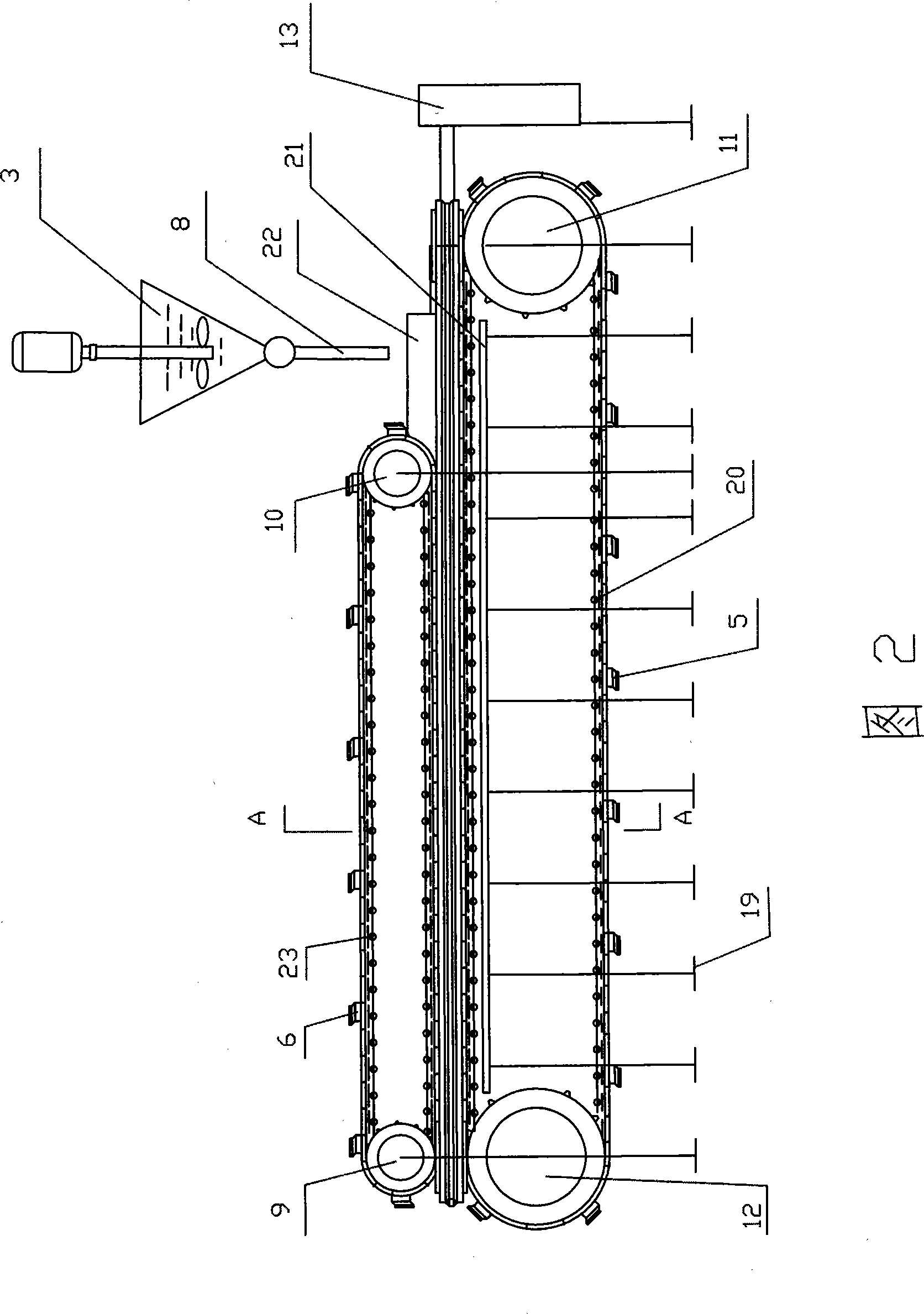

[0050] The continuous stirring feeder pours the prepared slurry into the slurry frame 22 through the feeding pipe 8, and the replaceable molds 5A, 7A, 5A1, 7A1 that can be fixed on the conveyor belt and the additional molding hollow tube mold 24 and additional The A-type gypsum hollow block mould, which is formed by buckling the forming tenon mold 25 together, is filled with slurry, the mold machine continues to rotate, and the speed of movement is controlled, so that the A-type gypsum block basically solidifies within a few tens of meters. , demoulding, transportation and stacking for the next step. This type of machine produces boards, composite gypsum blocks, and simple-shaped gypsum blocks by changing molds. The production scale depends on the combination of various conditions such as the slurry formula and the length of the mold machine. The mold machi...

Embodiment 2

[0051] Embodiment 2: (Fig. 12) Conveyor belt type block mold machine 3 assembled by 3 mold machines produces A-type gypsum hollow blocks, and one side of the block requires a matching shape, and a left or right horizontally placed The mold machine controls the shape of this side, and then the replacement molds 5A, 7A, 5A1, 7A1 that can be fixed on the conveyor belt and the additional molding hollow tube mold 24 are fastened together to form the A-type gypsum hollow block mold. The feeding pipe 8 pours the slurry into the slurry frame 22, the mold machine continues to rotate, and the A-type gypsum hollow block mold formed by buckling together is filled with slurry, and the movement speed is controlled to allow the A-type gypsum block in the mold to The blocks are basically solidified in the time of passing tens of meters, demoulded, transported and stacked to obtain the product.

Embodiment 4

[0052] Embodiment 4: (Fig. 1) the equipment conveyor belt type block mold machine 4 that is made up of 4 mold machines produces B type gypsum board ( Figure 5 ), both sides of the plate are required to have a matching shape, and two left and right horizontally placed mold machines are used to control the shape of the two sides. The B-type gypsum plate mold is composed of an additional mold hollow tube and 5B, 7B, 5B1, 7B1. The slurry is poured into the slurry frame 22 through the feeding pipe 8, the mold machine continues to rotate, and the B-type gypsum board mold is fastened to make the B-type gypsum board in the mold basically solidify in the time of tens of meters of length, demoulding , Transport and stack to get the product. Although there are many requirements for tools, the requirements for replaceable molds are low, and the manufacturing and maintenance costs are low.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com