Gypsum block continuous production apparatus capable of adjusting thickness

A technology for gypsum blocks and production equipment, which is applied in the direction of unloading devices, ceramic molding workshops, ceramic molding machines, etc., which can solve the problems of inability to adjust mold partitions, long block production time, and increased equipment investment, and achieve an The effect of small floor area, reduced mold opening process, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

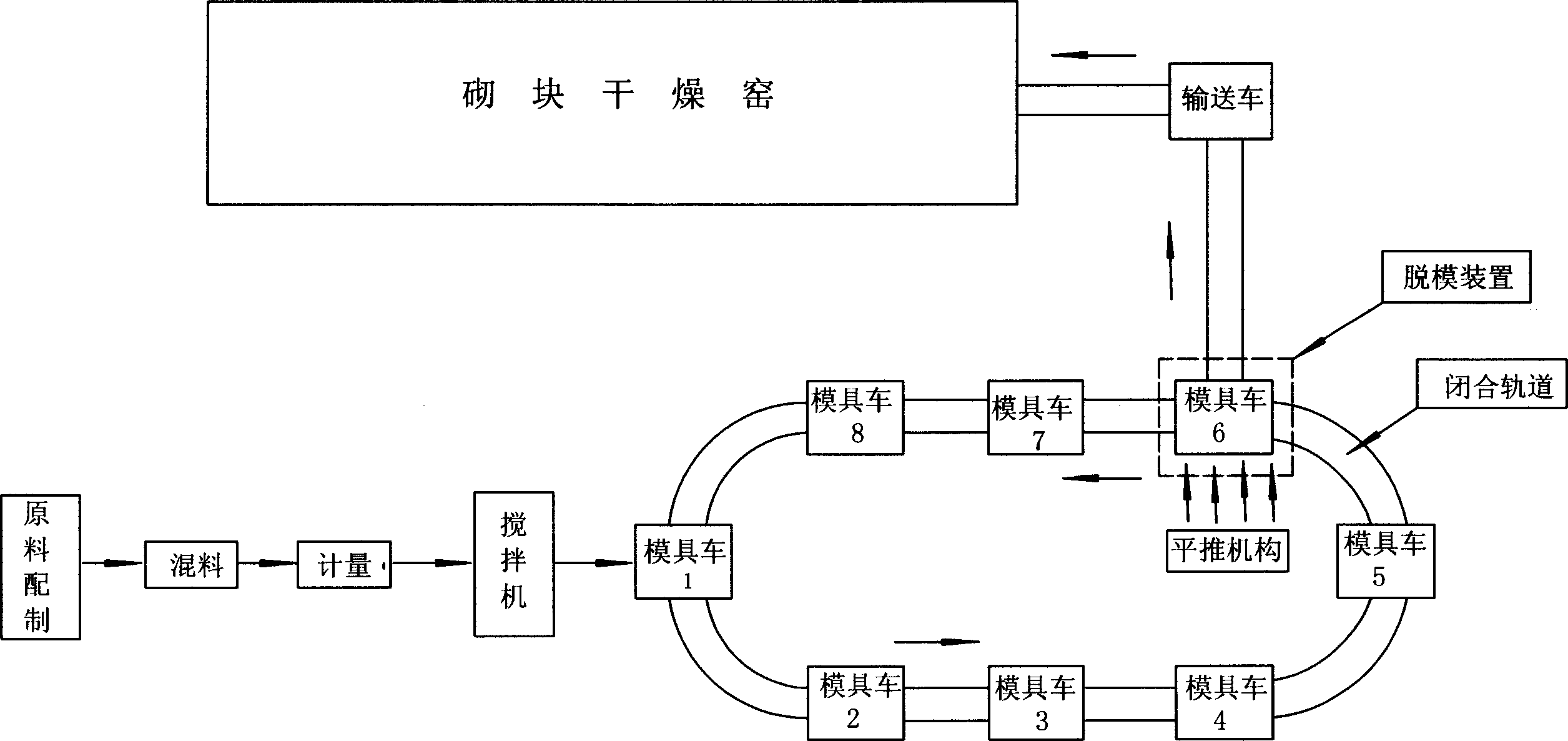

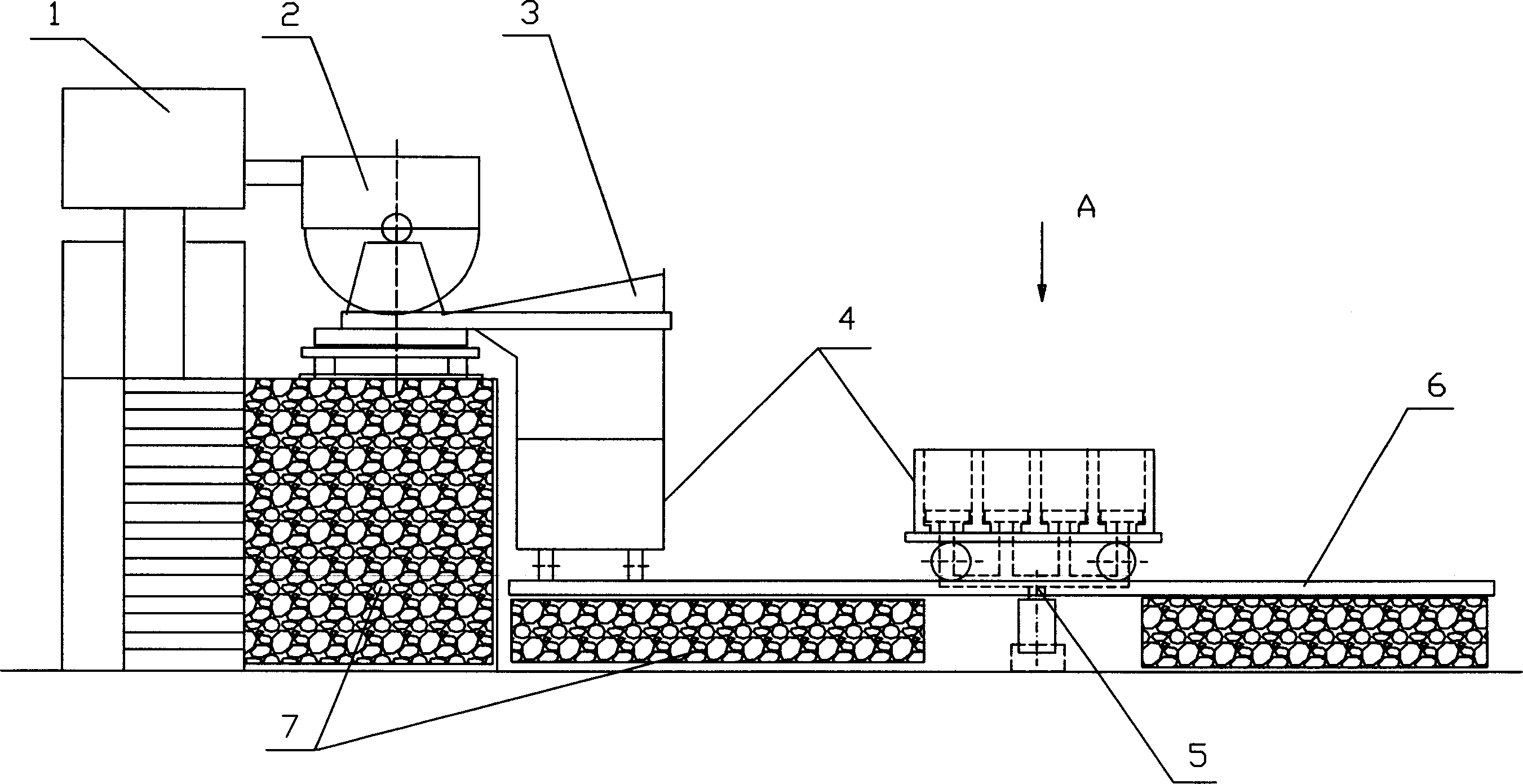

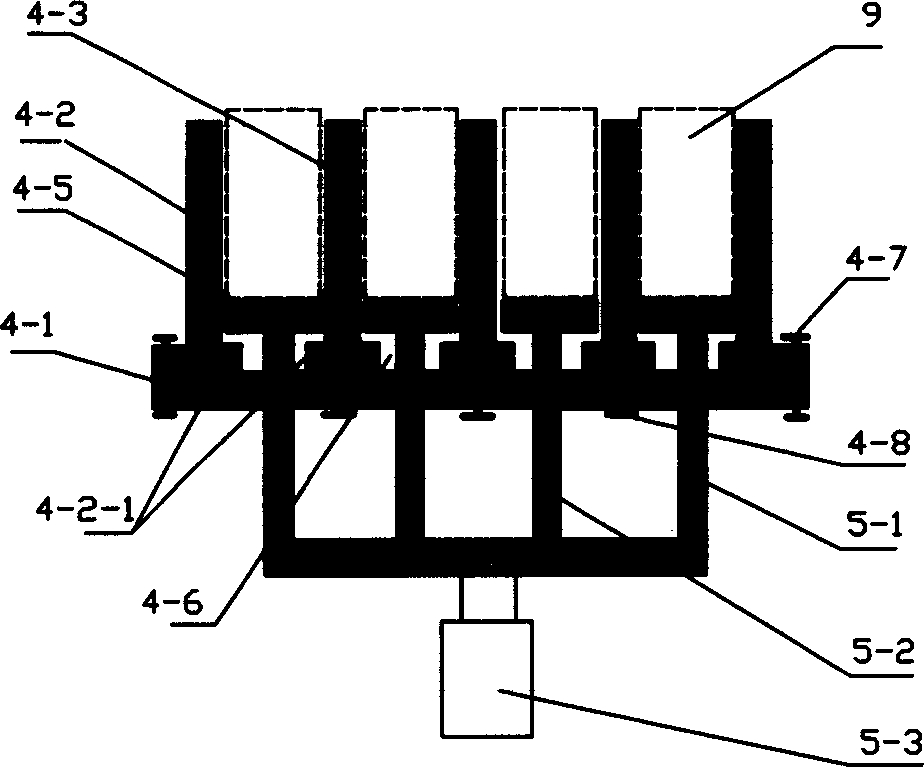

[0016] Such as figure 2 , 3 , 4, a continuous production device for gypsum blocks with adjustable thickness, including: raw material control system 1, mixer 2, grouting hopper 3, mold car 4, demoulding device 5 and conveying mechanism, installed on the mold car 4 The block mould, the mold car 4 moves circularly under the mixer 2, the grouting hopper 3 and the demoulding device 5 through the guide rail 6. The mold consists of an outer partition 4-2, an inner partition 4-3 arranged in parallel, front and rear baffles 4-4 placed on both sides of the partition, and shoulders 4-2-2 at the lower ends of the two partitions. 1. It consists of a mold base plate 4-5 that can move up and down along the mold cavity; there is an adjustment gap 4-6 between the shoulders 4-2-1 at the lower ends of the two partitions; the demoulding device 5 is installed on The mold car (4) can be positioned directly under the guide rail (6) at the set position, and it has an ejector frame 5-1 that can ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com