High-strength gypsum block making machine

A technology of block forming machine and high-strength gypsum, which is applied in ceramic forming machines, ceramic forming workshops, auxiliary forming equipment, etc., can solve the problems of low degree of automation, low production efficiency, inability to achieve continuous operation, etc., and achieves reasonable structure and improved The effect of work efficiency, improving work efficiency and equipment utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

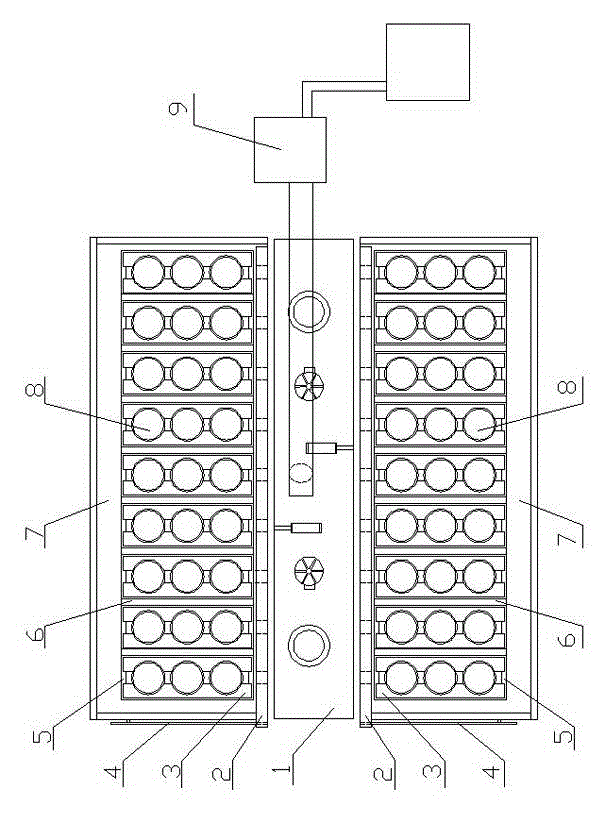

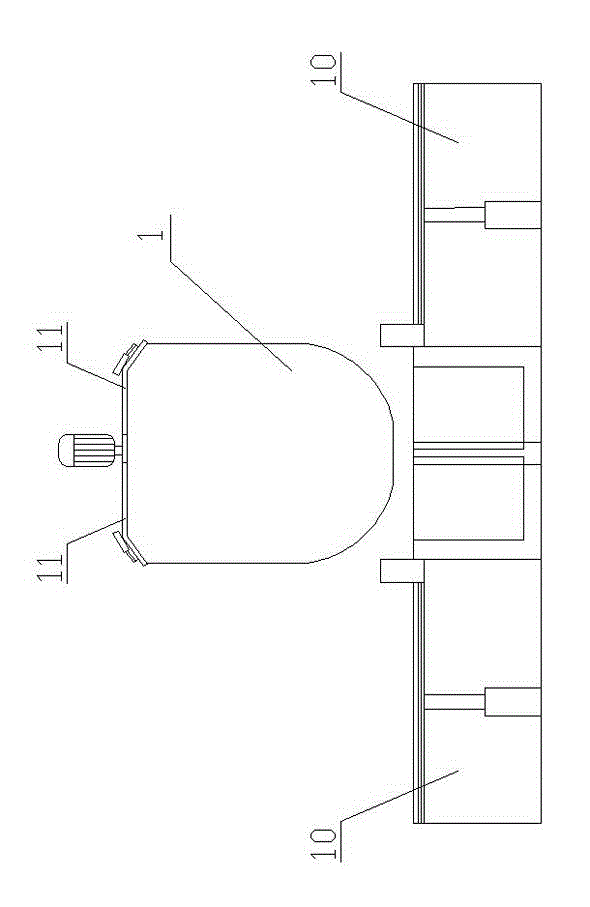

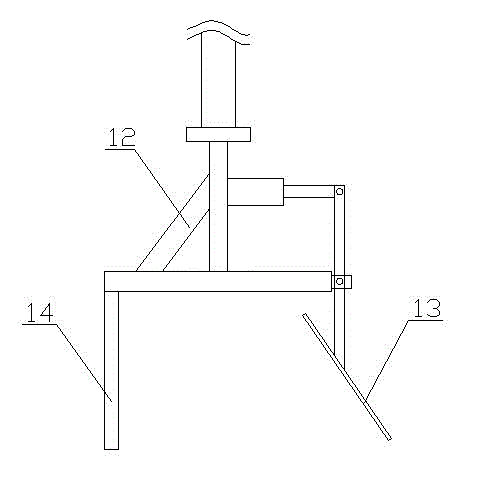

[0014] Embodiment 1, with reference to the accompanying drawings, a high-strength gypsum block forming machine, including a frame, a turning and mixing bin 1, a forming device 10 and a feeding system, the forming device 10 is provided with two sets, symmetrically located on the turning and stirring Below the two sides of the warehouse 1, the molding device 10 includes a box body, the upper surface of the box body is provided with an operating platform, and the box body is divided into several molding cavities 5 by longitudinal partitions 6, and each molding cavity 5 is provided with several molding cavities. A core column 8 fixedly connected with the bottom plate of the box body, a lifting bottom mold 3 is arranged above the bottom plate of the box body, and several mold holes corresponding to the core column 8 are opened on the bottom mold 3; a guide rod 4 is provided at one end of the operating platform The operating platform is provided with a scraper 2 connected to the guid...

Embodiment 2

[0017] Embodiment 2, in the high-strength gypsum block molding machine described in Embodiment 1, a remaining material platform 7 is provided on the operating platform at the end of the movement of the scraper 2, so that the stirred raw materials are poured into the molding cavity 5 At the same time, the leftover material on the leftover material platform 7 is crushed and added together in the molding cavity 5, which is convenient for adding and can save materials simultaneously.

Embodiment 3

[0018] Example 3, in the high-strength gypsum block forming machine described in Example 1, the upper part of the overturning mixing bin 1 is provided with an upper cover, and the upper cover includes two symmetrically arranged covers 11, the described The cover body 11 is driven by the cylinder. When the mixing bin 1 is turned over for stirring, the upper cover is put on to prevent the raw materials from splashing out. When the stirring bin 1 needs to be turned over, it is only necessary to open the cover body 11 on the side to be turned over by driving the cylinder. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com