Digitalization processing method of gypsum mould

A processing method and plaster model technology, applied in the direction of stone processing tools, stone processing equipment, manufacturing tools, etc., can solve problems such as complex process and loss of precision, and achieve the effects of shortening the process, reducing manufacturing costs, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

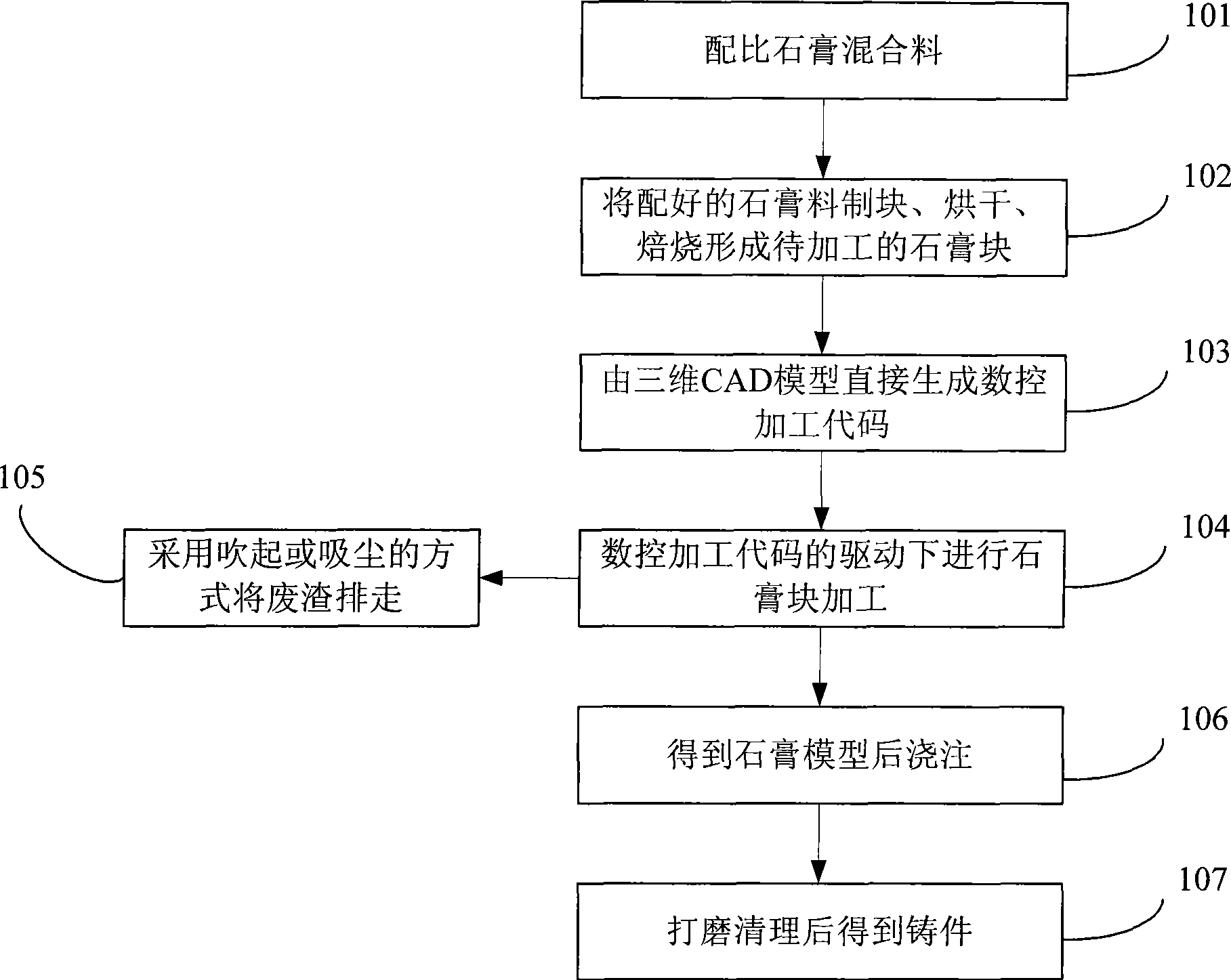

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

[0024] see figure 1 , a digital processing method for gypsum molding, the method comprises the steps of:

[0025] Step 101: Proportioning the gypsum mixture;

[0026] The dimensional accuracy of precision casting is generally within ±0.2mm. Due to the continuous dehydration of gypsum during the drying and roasting process, phase change occurs, accompanied by volume changes. Therefore, in order to prevent cracking of the gypsum mold, appropriate Filler, to reduce the linear shrinkage and crack tendency of gypsum type, improve the thermal conductivity of gypsum type, so that it has good room temperature and high temperature strength, and better dimensional accuracy. The gypsum is flue gas desulfurization gypsum, and the filler includes mullite powder and zircon powder. In order to improve the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com