Freeze-drying device with multistage energy recycling function

A technology of energy recovery and heat recovery, applied in heat recovery systems, applications, food preparation, etc., can solve the problems of high loss of cold energy, little use of system waste heat, and large consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

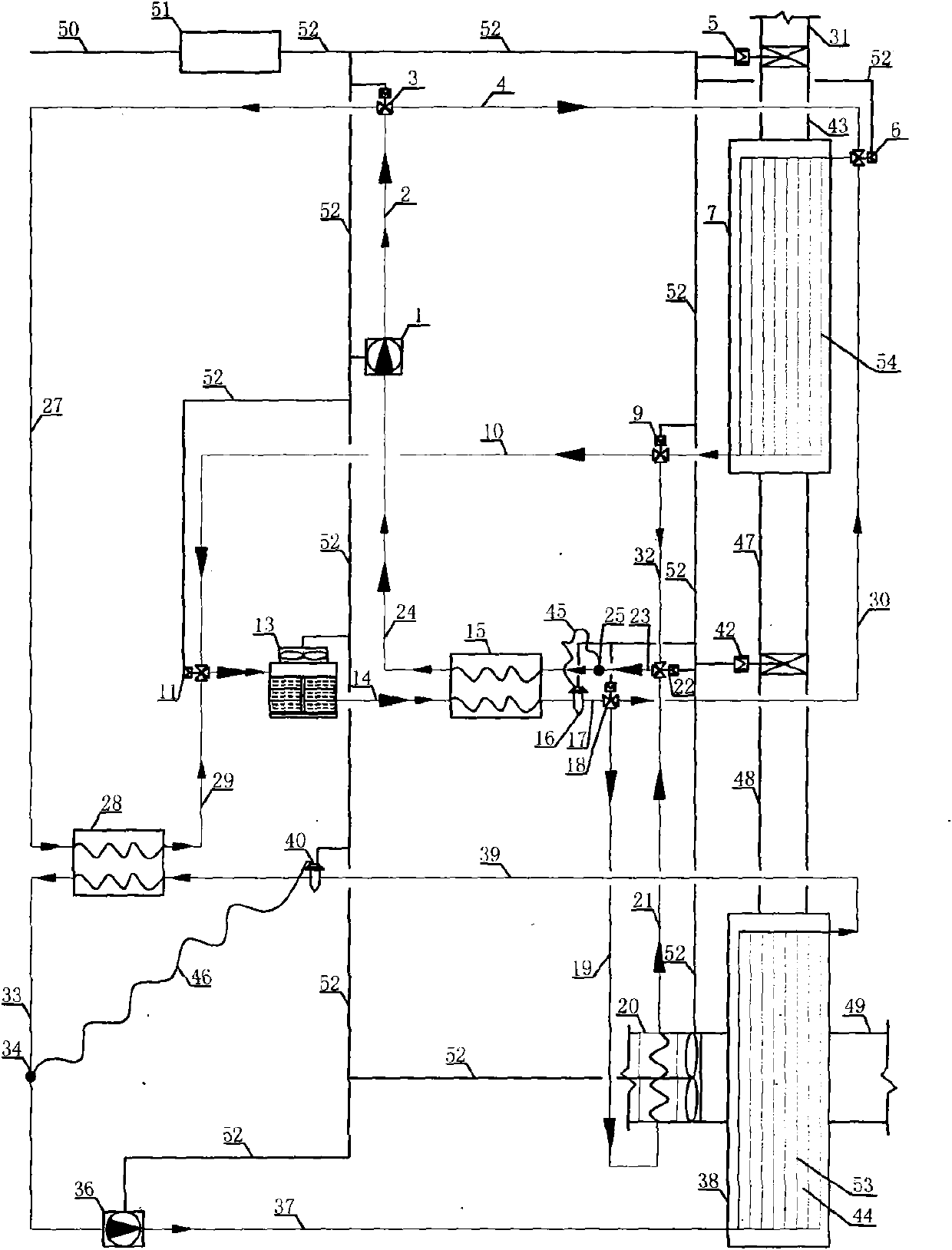

Embodiment 1

[0024] Embodiment 1: This freeze-drying equipment with multi-stage energy recovery and utilization function includes a cooler 13, a cooling fan 20, a compressor, an expansion valve, a cold recovery device 15, a fluid heat recovery device 28, a freeze-drying warehouse 38, The cold trap compartment 7 is equipped with a radiation heating plate 44 in the freeze-drying compartment 38 and a cold trap 54 in the cold trap compartment 7 . The cold trap storehouse 7 communicates with the cooler 13, the cold recovery device 15, and the compressor 1 through a pipeline and a switching valve mounted on the pipeline.

[0025] In the present embodiment, it is: there is a pipeline 10 communicated with it at one end of the cold trap chamber 7, and one end of the cold trap chamber 7 communicates with the cooler 13 through the pipeline 10, and a switching valve is housed on the pipeline 10, which are respectively control valves. Valve 9 and three-way control valve 11, control valve 9 is installed...

Embodiment 2

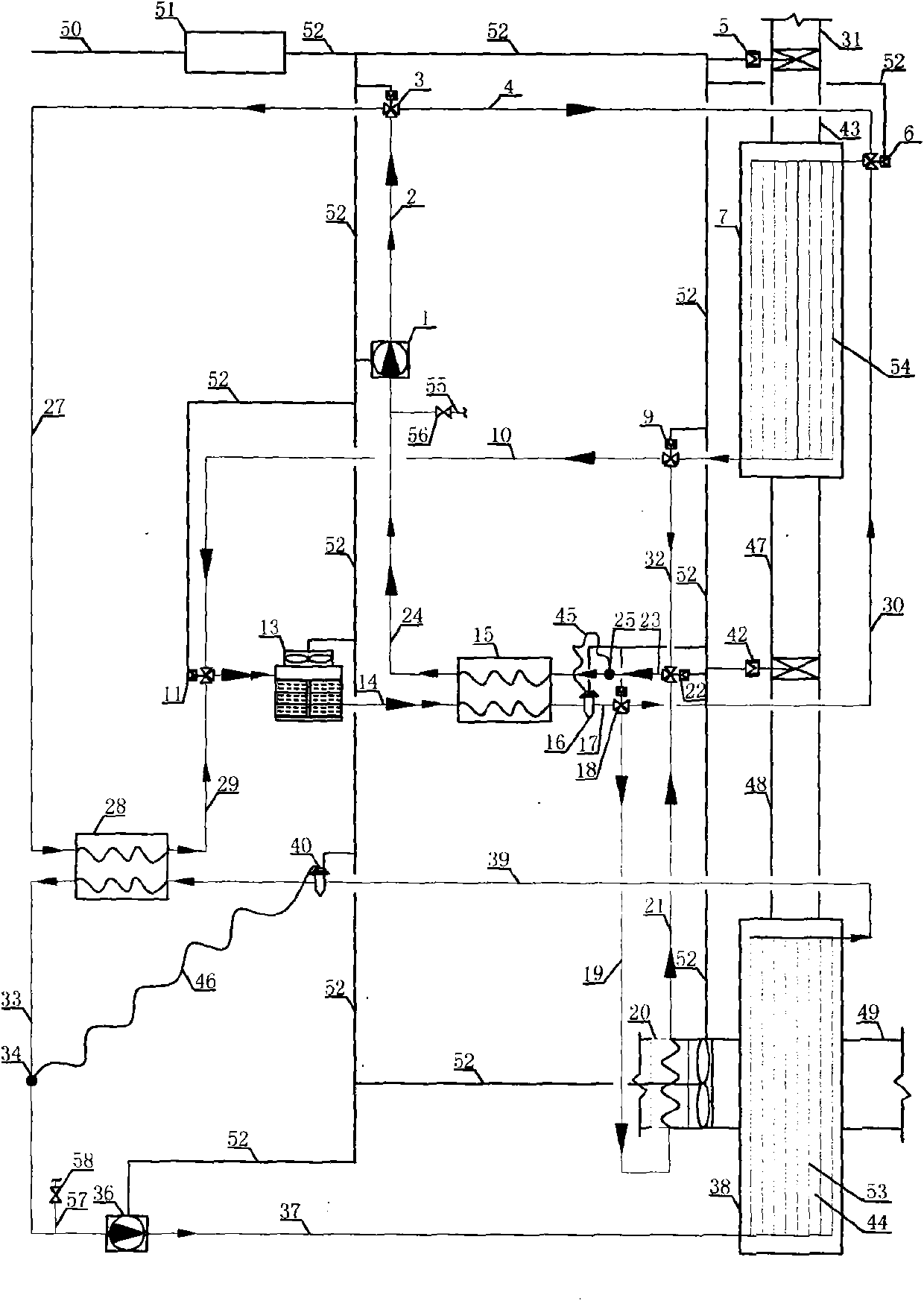

[0032] Embodiment 2: The structure of this embodiment is similar to that of Embodiment 1, except that a liquid replenishment pipe 55 and a liquid replenishment pipe 57 and valves 56 and valves for controlling them are respectively installed on the fluid delivery pipe 24 and the fluid delivery pipeline inlet pipe 33 58. The liquid replenishing pipe and its valve are installed on the pipeline connected to the compression inlet of the compressor or high-pressure heat pump. Other structures are identical with embodiment 1 (as figure 2 shown).

Embodiment 3

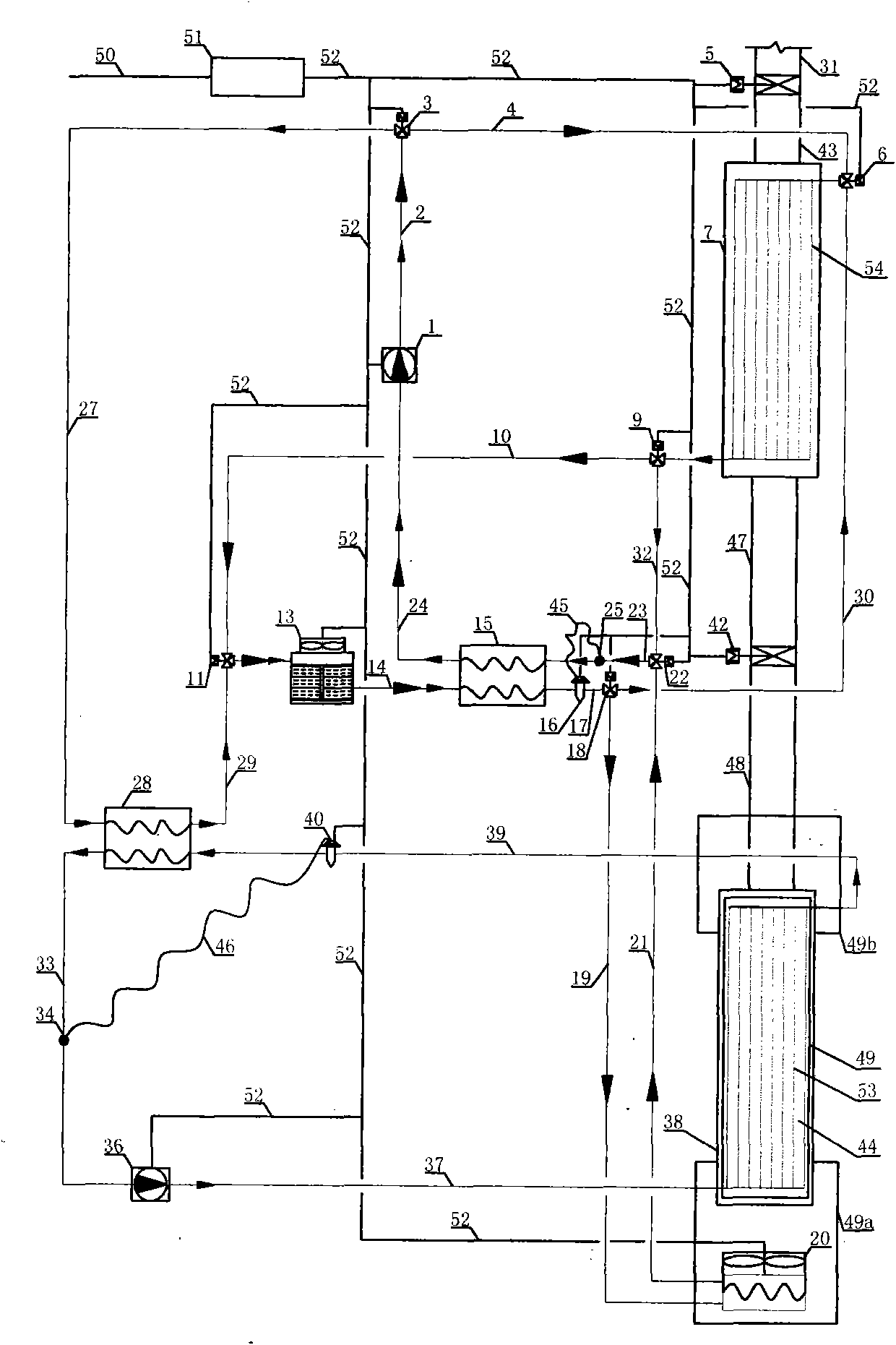

[0033] Embodiment 3: In this embodiment, the two ends of the freeze-drying warehouse 38 are provided with cold air boxes 49a and 49b, the cold air boxes 49a and 49b are integrated with the freeze-drying warehouse 38, and the cold air boxes 49a and 49b are communicated through the air duct 49 , the fan 20 is located in one of the cold air boxes (such as image 3 , Figure 4 Shown); The structure of other parts is identical with the structure of other parts in embodiment 1 or embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com