Heat radiation device for loop heat pipe with enhanced evaporation section used in LED lamp

A technology of LED lamps and cooling devices, which is applied in cooling/heating devices of lighting devices, lighting devices, semiconductor devices of light-emitting elements, etc., to achieve the effects of improving adaptability and application range, easy manufacturing, and reducing thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

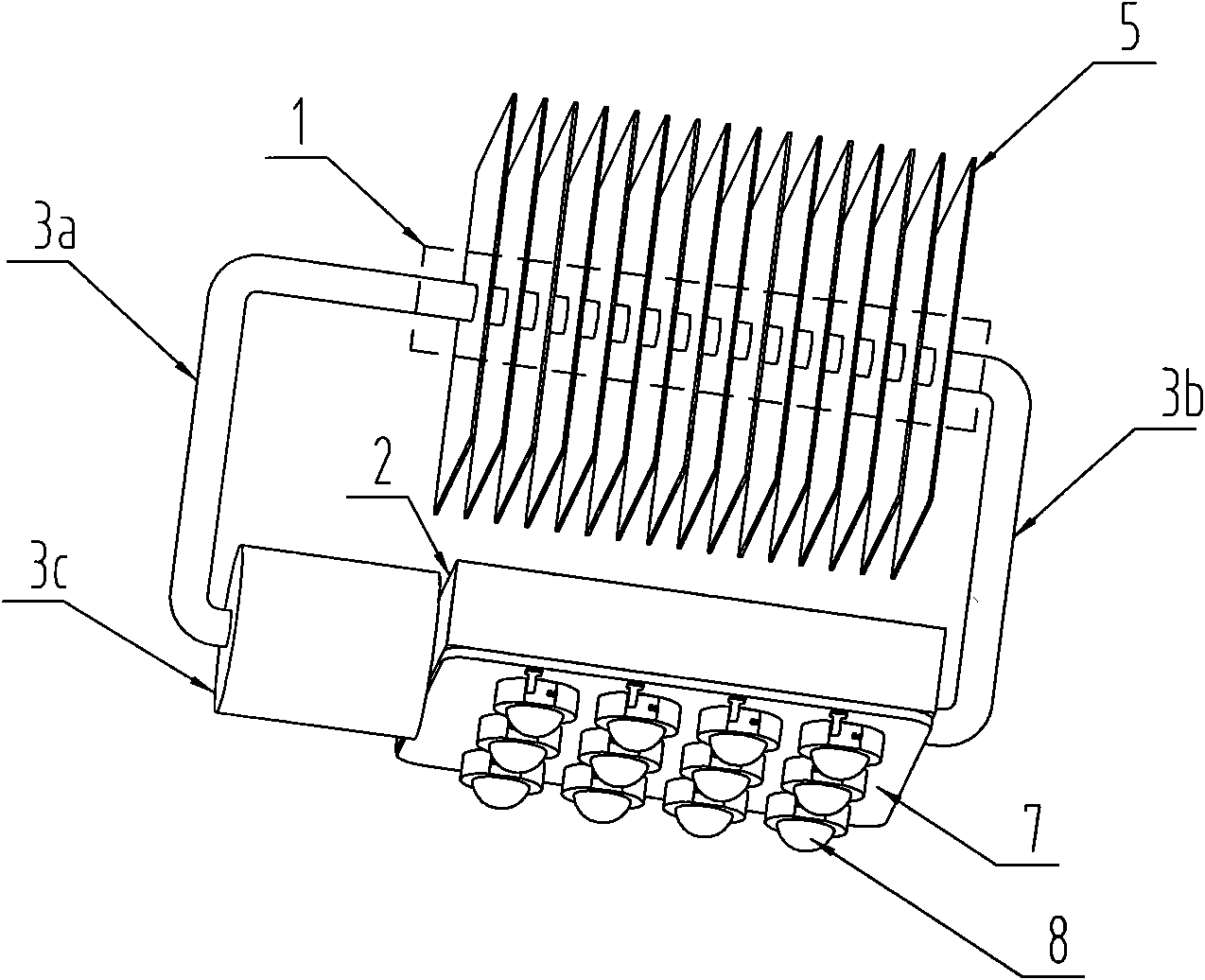

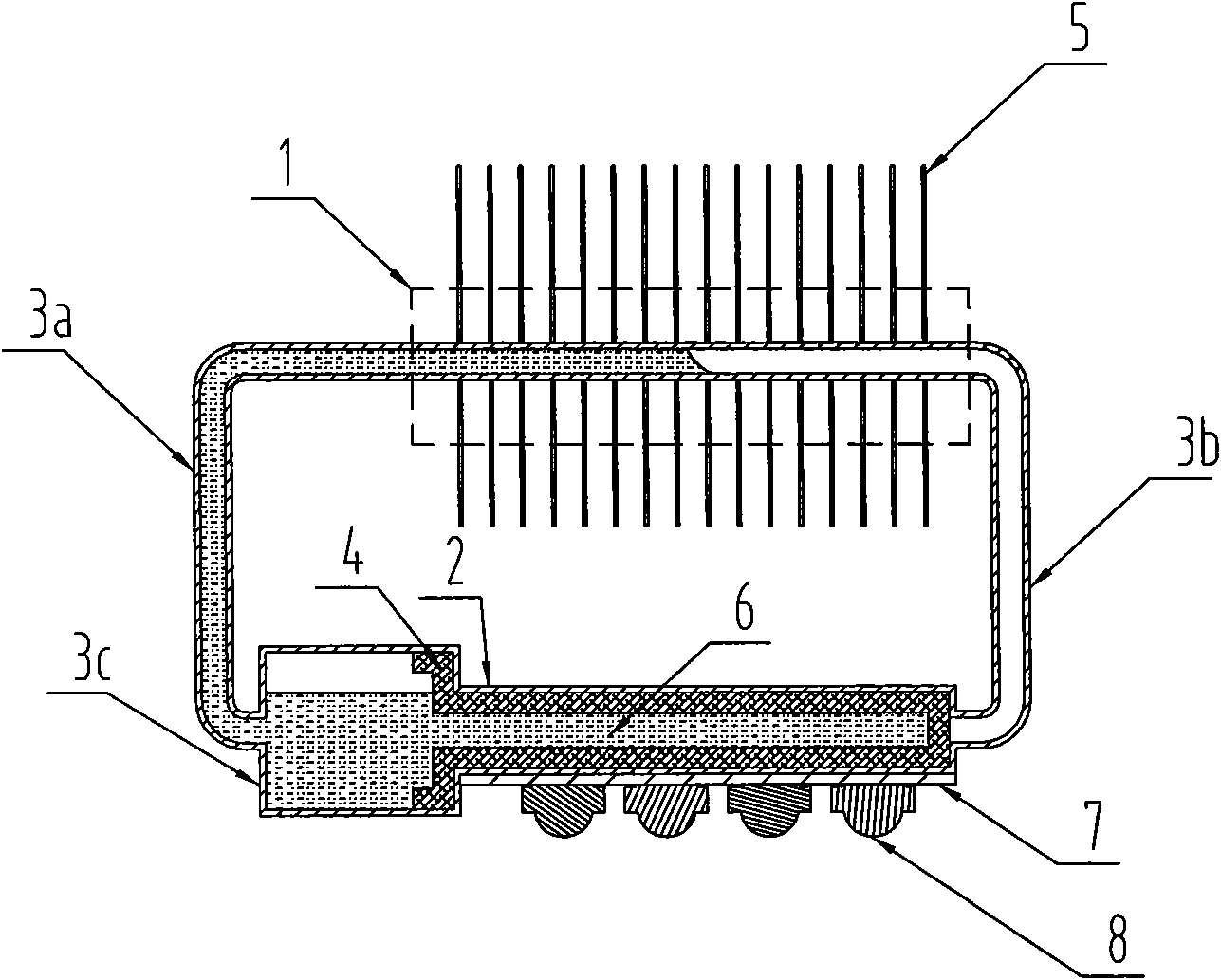

[0016] Such as figure 1 , figure 2 As shown, the LED lamp adopts the loop heat pipe cooling device of the enhanced evaporating section, which is composed of a heat pipe, a heat sink 5, a working liquid 6, and the like. The heat pipe is a circuit pipe with a sealed cavity, which has an enhanced evaporation section 2, a return section 3a, a steam section 3b, a compensation chamber 3c, and a condensation section 1. The enhanced evaporating section 2 is arranged on the back of the heat source of the LED lamp composed of the LED circuit substrate 7 and the LED light source 8. The cross-sectional shape of the enhanced evaporating section 2 is square or rectangular, and the material is a metal material with high thermal conductivity. The enhanced evaporating section 2 are respectively welded with the compensation chamber 3c and the steam section 3b. The inside of the loop tube is evacuated to a proper vacuum, the capillary structure 4 is set, and an appropriate amount of working l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com