Power battery module based on air, hot pipe and phase-change material coupled cooling

A technology of phase change materials and power batteries, applied in the direction of secondary batteries, circuits, electrical components, etc., to achieve enhanced heat transfer effects, simple structure, and efficient heat management effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

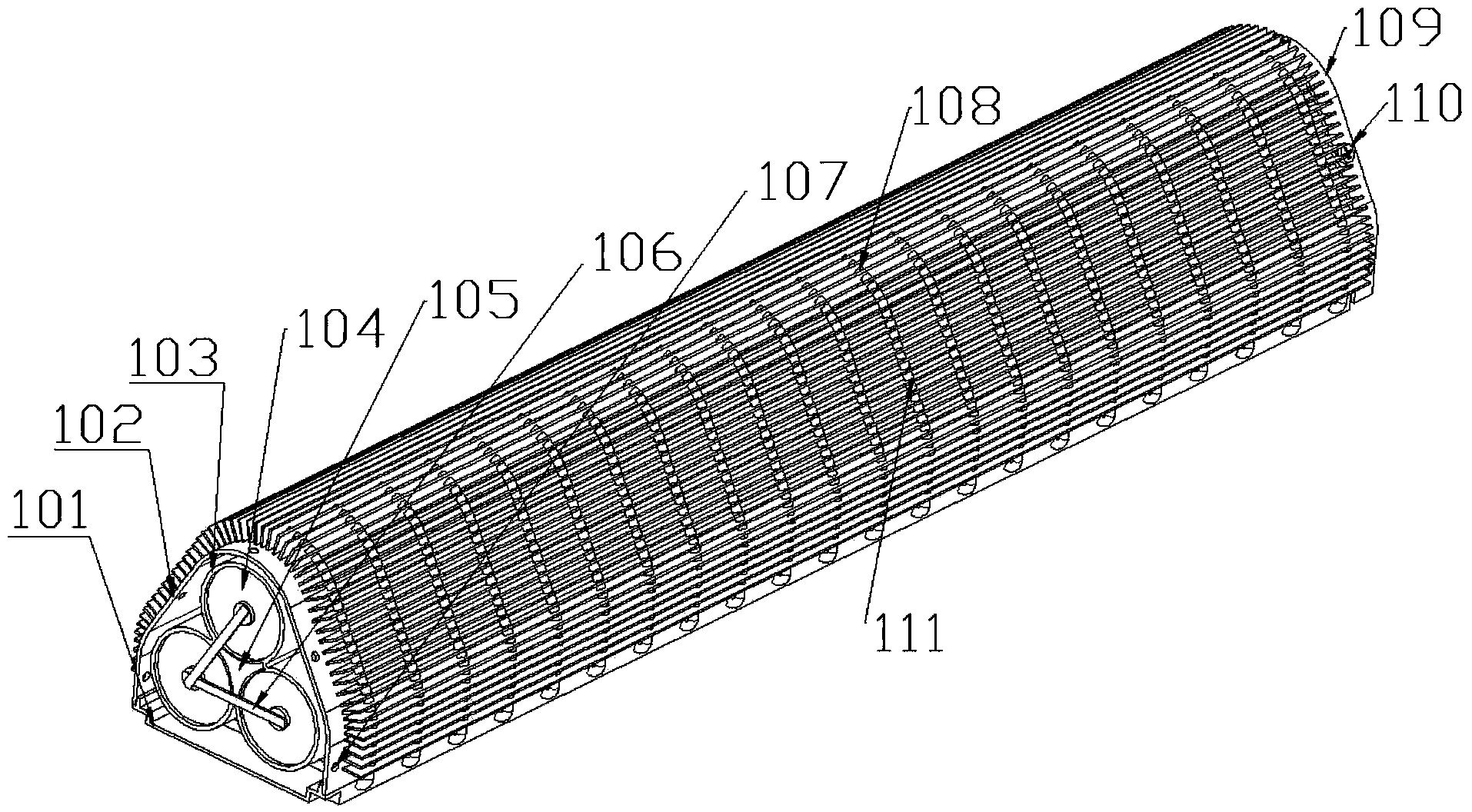

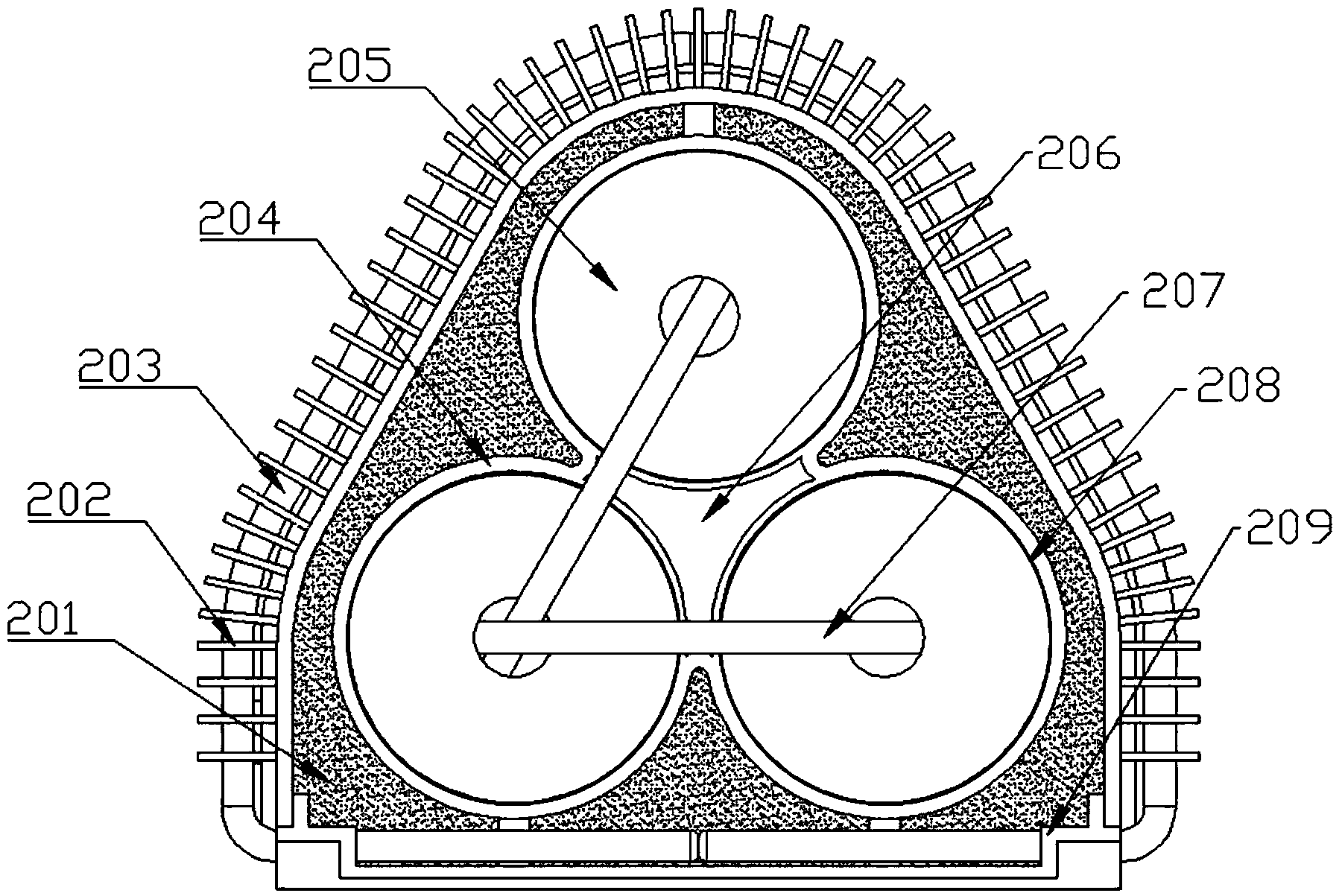

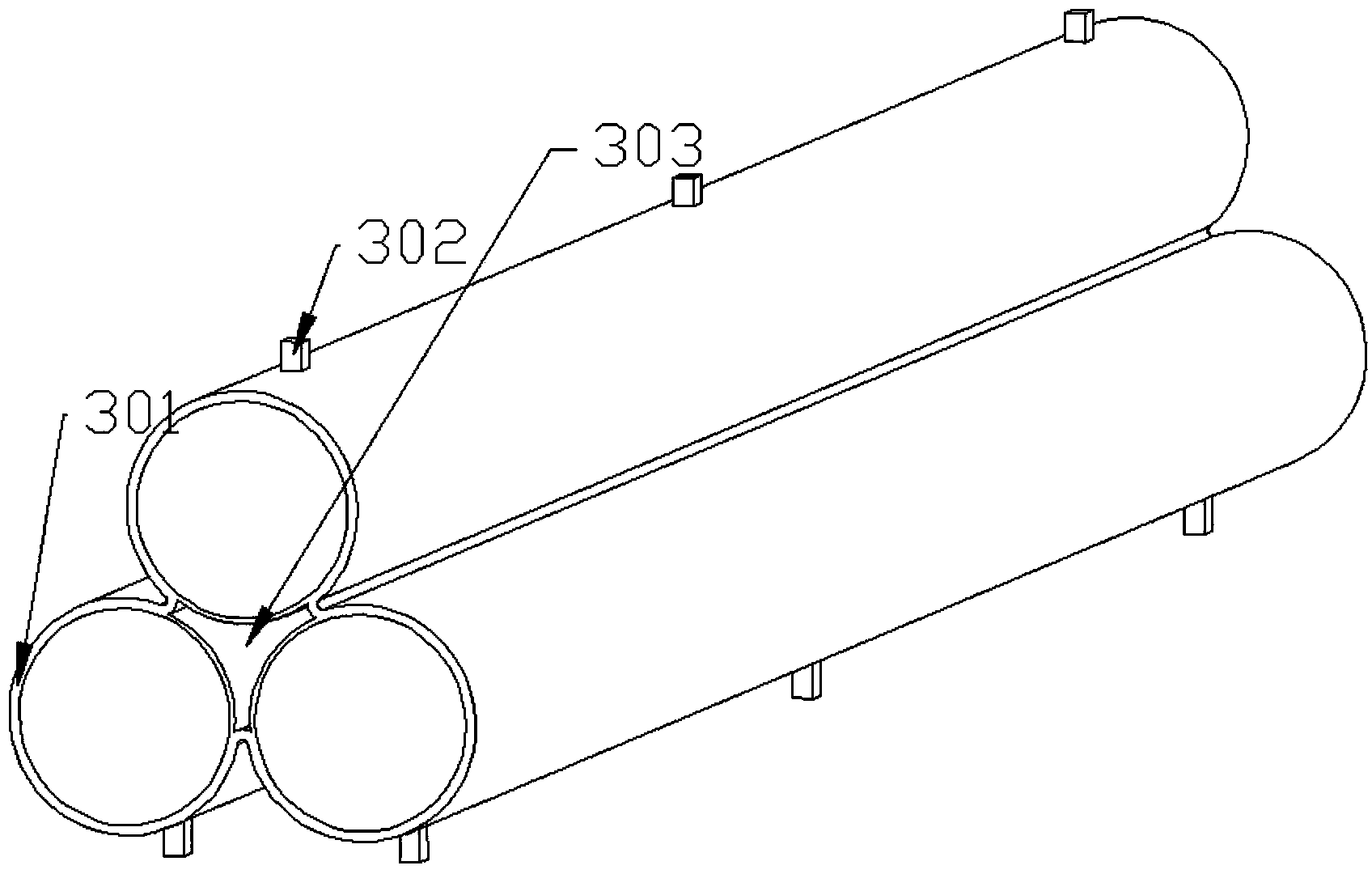

[0025] Embodiment: The battery module includes: base 101, fins 202, shell cover 102, clover sleeve 103, phase change material 201, heat pipe 108, end cap 109, multi-purpose channel 105, electrode connecting piece 106 and sealing gasket 601; A shell cover 102 is connected to the base 101, and fins 202 are densely distributed outside the shell cover 102. There are heat pipes 108 on the fins 202. There is a clover sleeve 103 in the shell surrounded by the base 101 and the shell cover 102. The two ends of the body are connected with end caps 109; each cylinder of the clover sleeve 103 is equipped with a number of cylindrical battery cells connected in series, and the number of battery cells connected in series in the battery pack in each cylinder is the same. The end of the cylinder is connected with an electrode connecting piece 106; the battery pack is radially fixed by the clover-shaped sleeve and axially fixed by the end cap, and the clover-shaped sleeve is connected with each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com