Efficient flux barrier motor based on hybrid cooling technology

A hybrid cooling and magnetic flux technology, applied in cooling/ventilation devices, electrical components, electromechanical devices, etc., can solve problems such as insufficient cooling of rotors and bearings, shortened mechanical life of motors and systems, and reduced overall energy efficiency of motors. , achieve the effect of suppressing high and low order non-working harmonic content, improving motor efficiency, and reducing various losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to further explain the technical solution of the present invention, it will be described in detail below in conjunction with the accompanying drawings.

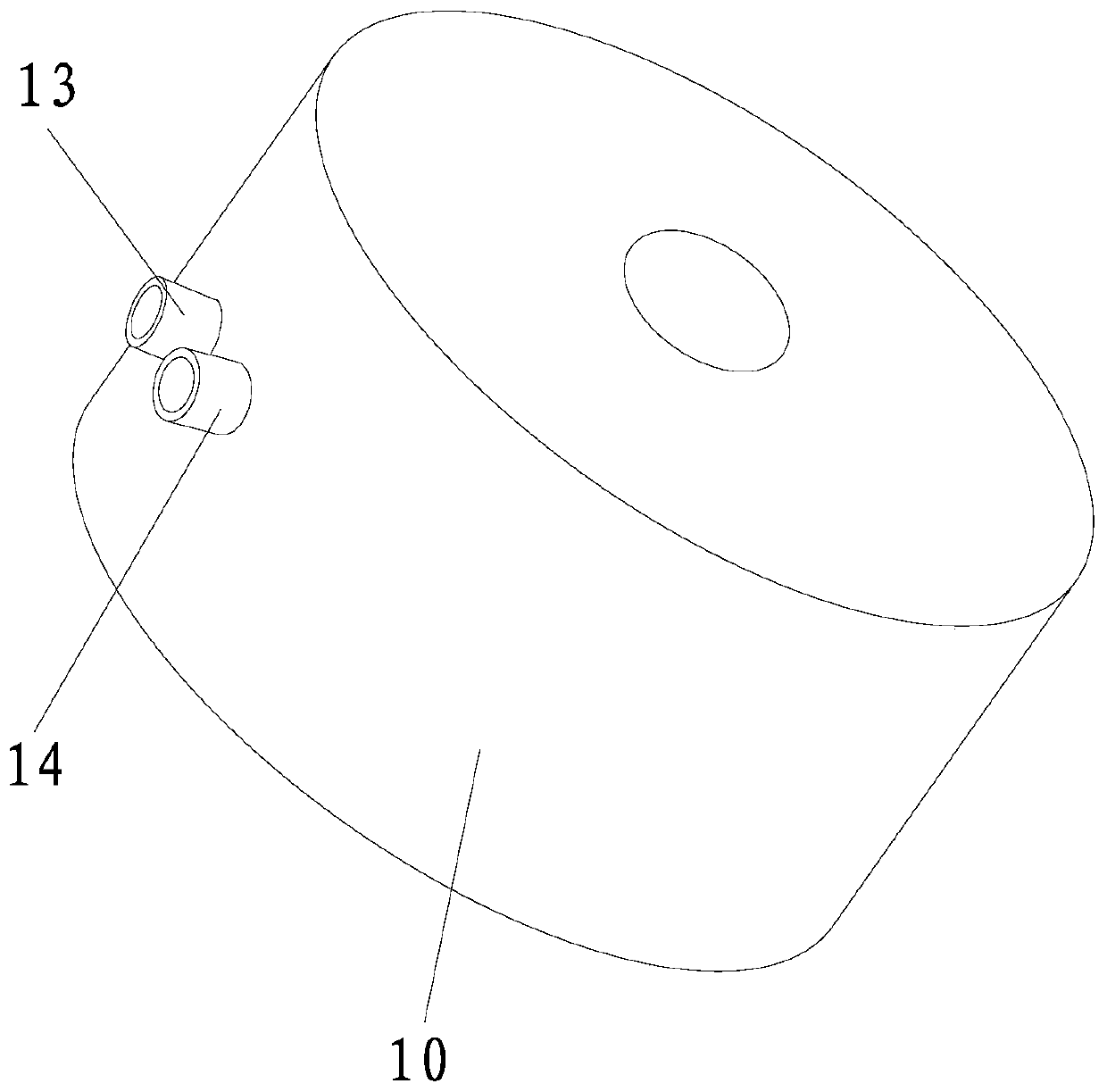

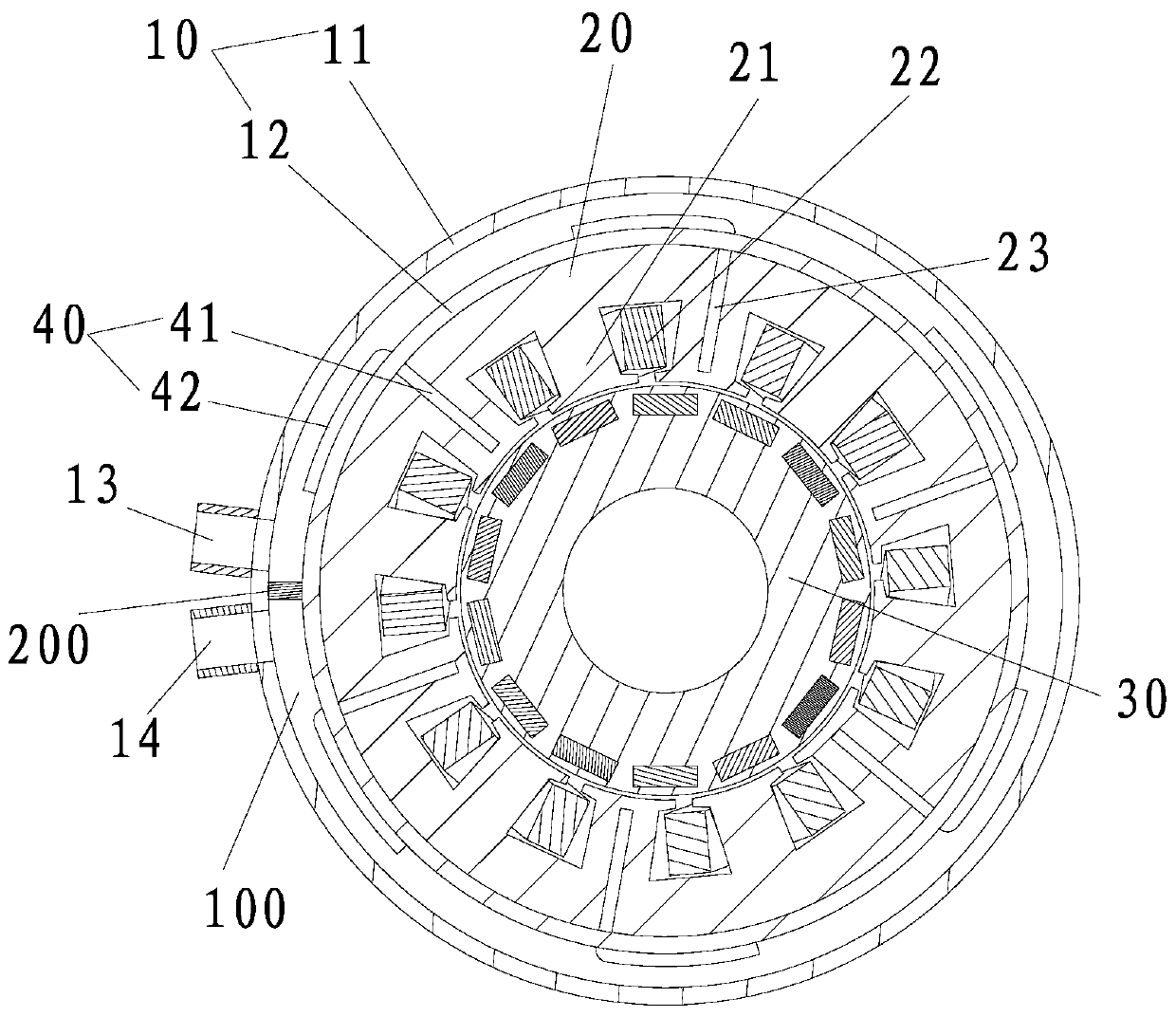

[0039] refer to Figure 1 to Figure 8 , a high-efficiency flux barrier motor based on hybrid cooling technology, comprising a casing 10, a stator assembly disposed in the casing 10, and a rotor assembly disposed in the stator assembly, the casing 10 including a motor inner casing 12 and a motor casing body 11, a coolant channel 100 is formed between the motor inner housing 12 and the motor outer housing 11, the two ends of the motor inner housing 12 and the two ends of the motor outer housing 11 are all formed to cover, and the motor outer housing 11 is provided with The liquid inlet 13 and the liquid outlet 14 are connected to the cooling channel. In the embodiment, the cooling liquid is water.

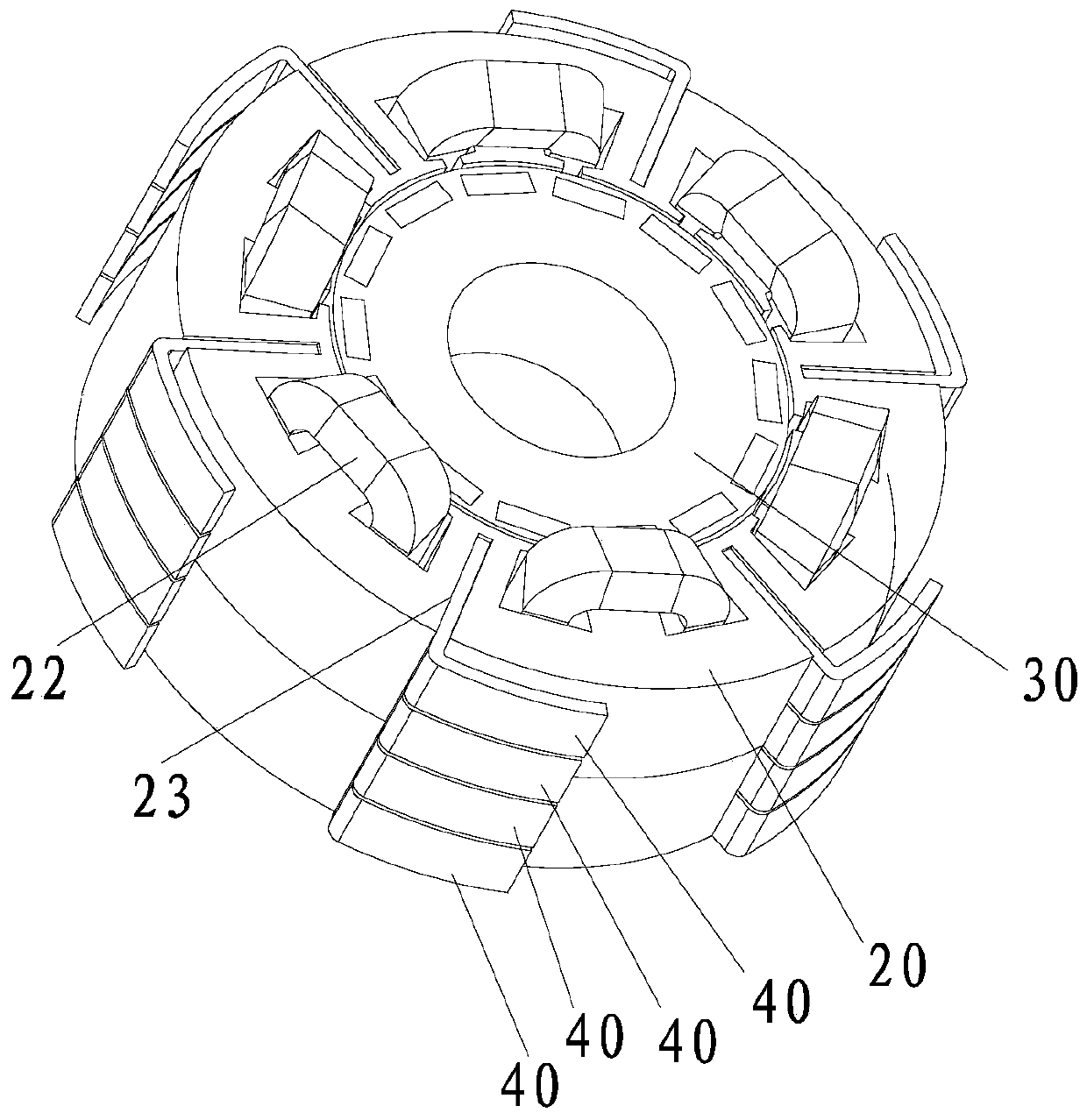

[0040] The stator assembly in the present invention includes a stator 20, a stator tooth 21 formed in the stator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com