Circular direct methanol fuel cell of high performance and low cost

A methanol fuel cell, low-cost technology, applied in the direction of fuel cells, fuel cell grouping, fuel cell parts, etc., can solve the problems of not having a battery pack, etc., and achieve the effects of low manufacturing cost, reasonable structure, and small impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

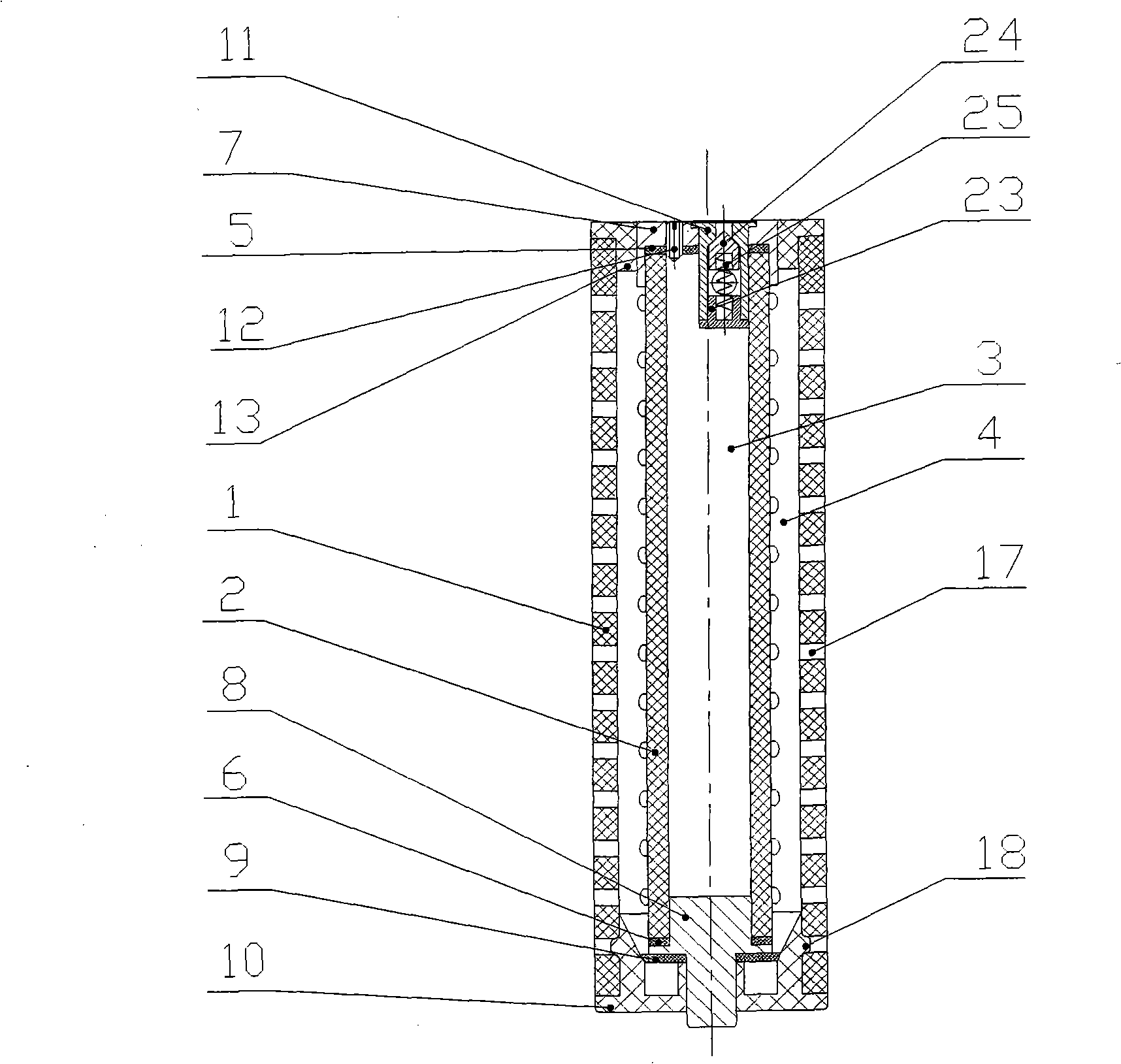

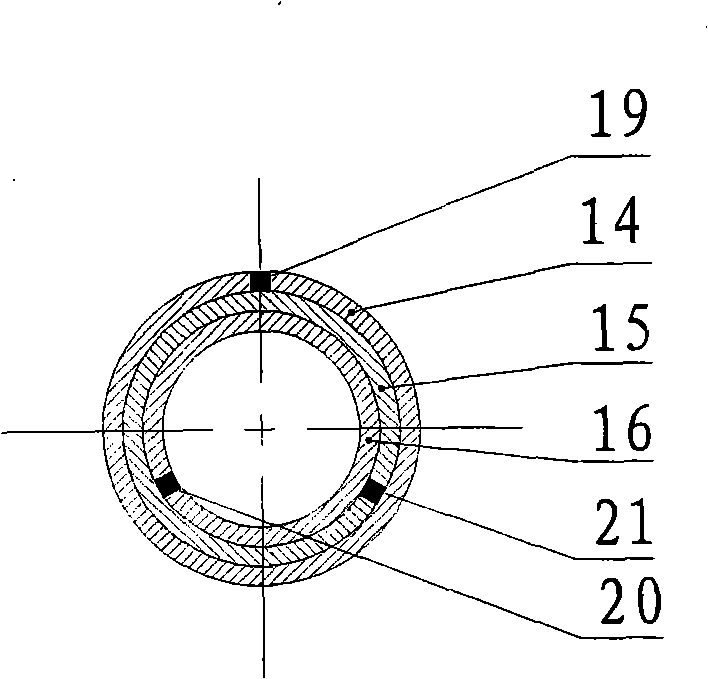

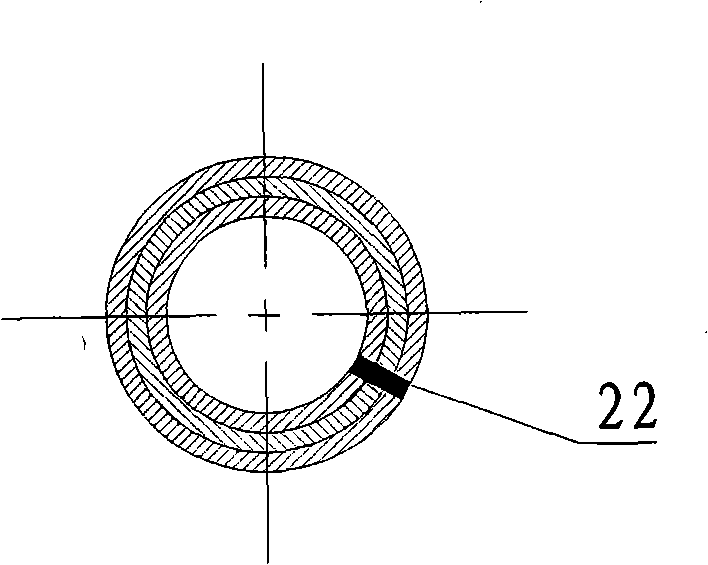

[0022] A high-performance, low-cost circular direct methanol fuel cell, the size of which is the same as that of No. 7, No. 5, No. 2 or No. 1 dry batteries, including a casing 1, a membrane electrode 2 is arranged inside the casing, and a battery liquid chamber is inside the membrane electrode 3. There is an air chamber 4 between the casing and the membrane electrode, insulating sealing rings 5 and 6 are arranged at both ends of the membrane electrode, and the cathode output part 7 and the anode output part 8 are respectively arranged at the cathode end and the anode end of the battery pack, and the outside of the anode output part A water-conducting and gas-blocking film 9 is provided, and a water collector 10 is provided on the outside of the water-conducting and gas-blocking film. 25), a drain screw device 12 communicating with the battery liquid chamber is arranged on the cathode output member. A support ring 13 is provided between the cathode output and the end of the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com