Minisize chromatographic column box with high precision temperature control system

A temperature control and temperature control module technology, applied in temperature control, non-electric variable control, control/regulation system, etc., can solve the problem of imprecise temperature control, etc., and achieve good response time, excellent thermal conductivity, and high strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

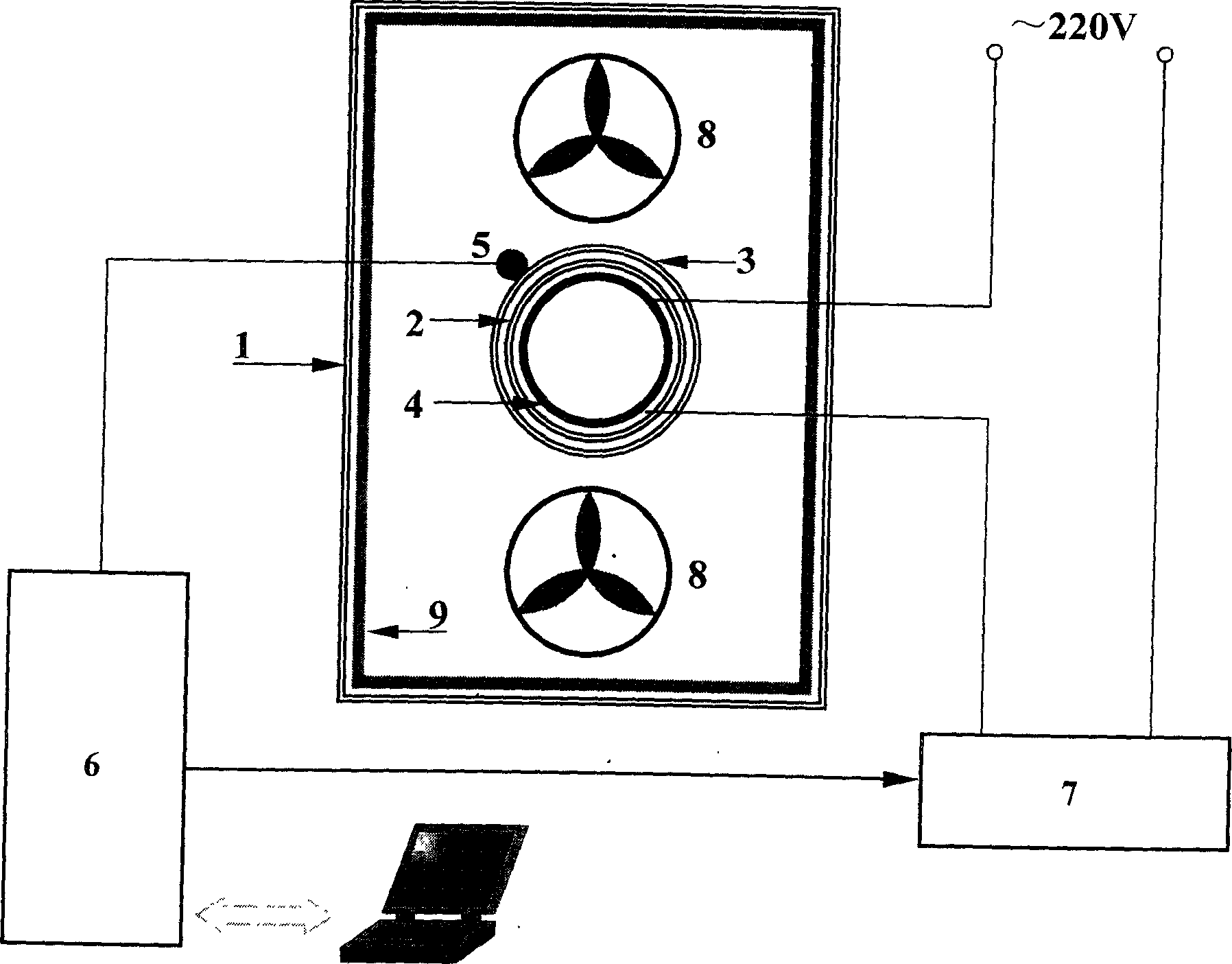

[0036] Such as figure 1 As shown, the high-precision temperature control miniature chromatographic column box of the present invention includes a box body 1, and the external dimensions of the box body are length*width*height equal to 80mm*80mm*80mm, and the capillary column heating skeleton 2 and the winding The capillary column 3 on the skeleton, the heating device 4 and the precision thermal resistance 5 arranged on the inner wall of the skeleton, and the temperature control system arranged outside the box. The capillary column heating skeleton is made of aluminum-magnesium alloy material, and the skeleton is cylindrical, with a cylinder diameter of 60mm and a cylinder height of 60mm. The total winding length is 1 meter, and the arrangement is closely arranged. The heating device is a silicone rubber flexible electric heating film coated on the inner wall of the frame, which is composed of a high temperature resistant fiber reinforced material as the main insulator and an ...

Embodiment 2

[0042] Such as figure 1 As shown, the high-precision temperature control micro-chromatographic column box of the present invention includes a box body 1, and the outer dimensions of the box body are length*width*height equal to 160mm*160mm*160mm, and the capillary column heating skeleton 2 and the winding The capillary column 3 on the skeleton, the heating device 4 and the precision thermal resistance 5 arranged on the inner wall of the skeleton, and the temperature control system arranged outside the box. The capillary column heating skeleton is made of aluminum-magnesium alloy material, and the skeleton is cylindrical, with a cylinder diameter of 120mm, a cylinder height of 90mm, and a wall thickness of 1mm. wrapped around the skeleton. The total length of the capillary columns is 60 meters, and the arrangement is closely spaced. The heating device is a silicone rubber flexible electric heating film coated on the inner wall of the frame, the thickness of the electric heati...

Embodiment 3

[0049] Such as figure 1 As shown, the high-precision temperature control micro-chromatographic column box of the present invention includes a box body 1, and the outer dimensions of the box body are length*width*height equal to 120mm*120mm*120mm, and the capillary column heating framework 2 and the winding The capillary column 3 on the skeleton, the heating device 4 and the precision thermal resistance 5 arranged on the inner wall of the skeleton, and the temperature control system arranged outside the box. The capillary column heating frame is made of aluminum-magnesium alloy material, and the frame is cylindrical, with a cylinder diameter of 100mm, a cylinder height of 70mm, and a wall thickness of 0.2mm. Wrapped tightly around the skeleton. The total length of the capillary column winding is 30 meters, and the arrangement is arranged at intervals. The heating device is a silicone rubber flexible electric heating film coated on the inner wall of the frame, the thickness of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com