Automatic hot water stirring cup

A technology of automatic stirring and hot water, applied in the field of water cups, can solve the problem that the water cup does not have a cooling function, etc., to achieve the effect of easy cleaning and fast heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

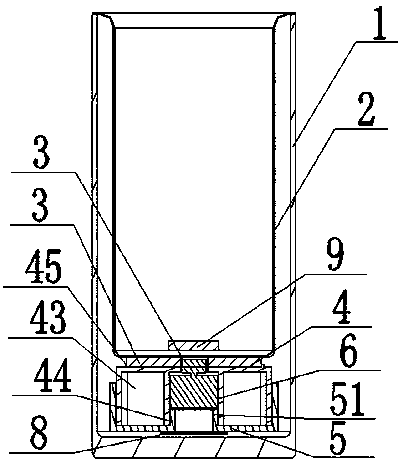

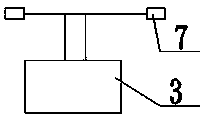

[0024] Such as Figure 1-3 As shown, a hot water automatic stirring cup includes a cup body 1, an inner container 2, the upper part of the inner container 2 is connected with the inner container 1, and a storage space is formed between the inner container 2 and the side wall and the bottom of the cup body 1. Cavity; one side of the power generation piece 3 is connected to the bottom outer surface of the inner tank 2, and the other side of the power generation piece 3 is connected to the upper surface of the metal cup bottom cover 4; the cup bottom 5 made of metal or plastic material is connected to the cup bottom cover 4, the cup bottom 5 and the cup bottom cover 4 form a heat-conducting medium accommodation chamber, and the heat-conducting medium is installed in the heat-conducting medium accommodation chamber; the motor 6 is arranged in the cup bottom cover 4, and the power generation piece 3 is provided with a through hole. The motor 6 is installed through the generator she...

Embodiment 2

[0031] The difference between this embodiment and Embodiment 1 is that in this embodiment, the motor is arranged under the power generating sheet, and no hole is needed in the middle of the generating sheet. The specific structure is as follows:

[0032] A hot water automatic stirring cup, comprising a cup body 1, an inner container 2, the upper part of the inner container 2 is connected with the cup body 1, and a receiving cavity is formed between the inner container 2 and the side wall and bottom of the cup body 1; One side of the sheet 3 is connected to the bottom outer surface of the inner tank 2; the other side of the power generation sheet 3 is connected to the upper surface of the metal cup bottom cover 4; the cup bottom 5 is connected to the bottom of the cup bottom cover 4, and the cup bottom 5 and the cup bottom cover 4 Form a heat-conducting medium accommodating chamber, and the heat-conducting medium is installed in the heat-conducting medium accommodating chamber;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com