Energy-saving device for separating maleic anhydride based on multi-stage condensation and two-stage absorption integration and process thereof

A secondary absorption and maleic anhydride technology, applied in the chemical industry, sustainable manufacturing/processing, organic chemistry, etc., can solve the problem of high energy consumption and achieve high maleic anhydride yield, good effect, and significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

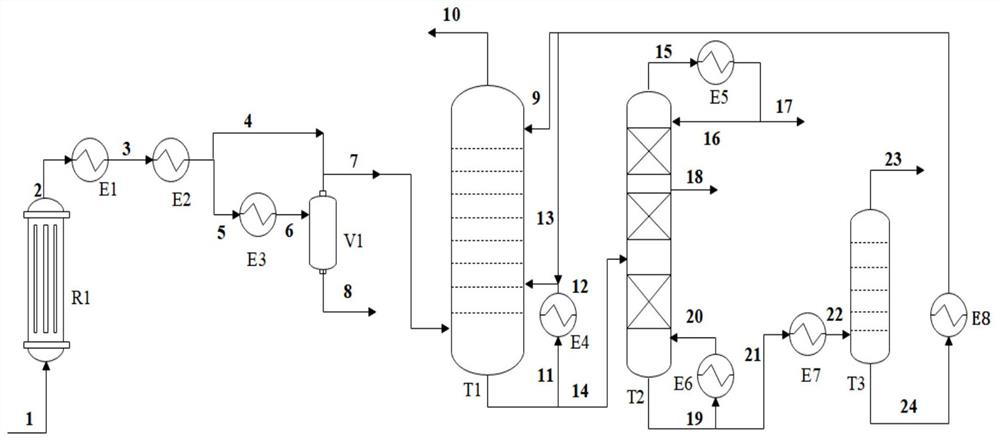

[0065] An energy-saving process based on multi-stage condensation and two-stage absorption integrated separation of maleic anhydride, comprising the following steps:

[0066] S1, 232251kg / h of air and 8244kg / h of benzene mixed to form the reaction raw material mixed gas 1 enters the maleic anhydride reactor R1 from the reaction raw material inlet, and generates a reaction product mixture with a maleic anhydride content of 3.2% through catalytic oxidation reaction Gas 2; the reaction product mixture gas 2 is cooled to 265°C by the reaction gas primary cooler E1, and enters the reaction gas secondary cooler E2 to continue cooling to 130°C;

[0067] S2. Maleic anhydride reaction gas with 240495kg / h maleic anhydride content of 3.2% is extracted from the outlet of reaction gas secondary cooler E2 and is divided into two streams of materials 4 and 5, which enter the absorption at the flow rates of 151512kg / h and 88983kg / h respectively The 25th tray of tower T1 and the reaction gas t...

Embodiment 2

[0081] An energy-saving process based on multi-stage condensation and two-stage absorption integrated separation of maleic anhydride, comprising the following steps:

[0082] S1, the reaction raw material mixed gas 1 formed by mixing 78144 kg / h of air and 2987 g / h of n-butane enters the maleic anhydride reactor R1 from the reaction raw material inlet, and generates a maleic anhydride content of 3.26% through catalytic oxidation reaction The reaction product mixture gas 2; the reaction product mixture gas 2 is cooled to 278°C by the reaction gas primary cooler E1, and enters the reaction gas secondary cooler E2 to continue cooling to 140°C;

[0083] S2. Maleic anhydride reaction gas with 3.2% maleic anhydride content of 81131kg / h is extracted from the outlet of reaction gas secondary cooler E2 and is divided into two streams of materials 4 and 5, which enter into the absorption at flow rates of 43000kg / h and 38131kg / h respectively The 25th tray of tower T1 and the reaction gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com