Novel pulse tube refrigerator

A technology of pulse tube refrigerator and pulse tube, which is applied in the direction of refrigerators, refrigeration and liquefaction, compressors, etc., can solve the problems that affect the efficiency, inconvenience, and constraints of refrigeration efficiency, and achieve the goal of improving refrigeration effect, precision, and efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

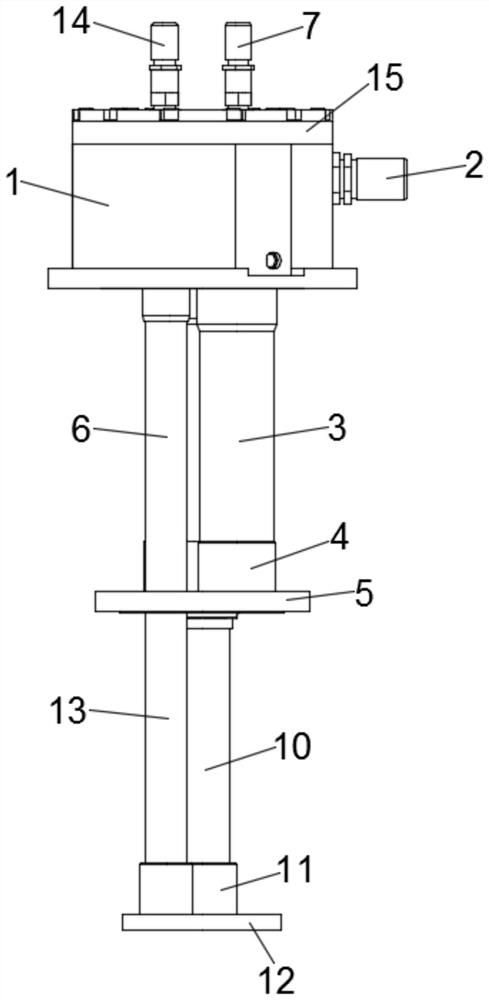

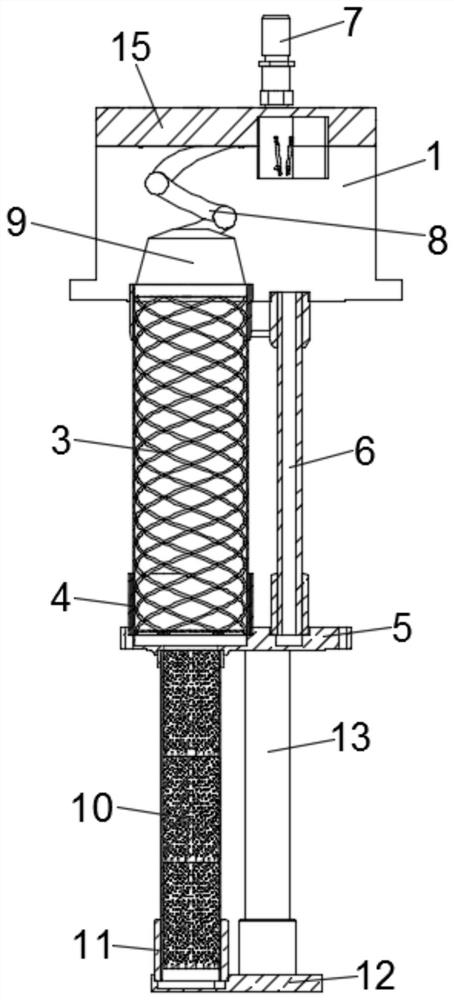

[0023] see Figure 1-2 , a new type of pulse tube refrigerator, comprising a cold head body 1 and an intake pipe 2, the side wall of the cold head body 1 is provided with an inlet pipe 2, the bottom of the cold head body 1 is provided with a primary refrigeration system, and the first The first-stage refrigeration system includes a first-stage heat storage tube 3, a first-stage heat exchanger 4, a first-stage cold plate 5, a first-stage pulse tube 6, and a first-stage heat storage tube 3. The bottom of the first-stage heat storage tube 3 is provided with a first-stage heat exchanger 4 The bottom of the primary heat exchanger 4 is provided with a primary cold plate 5, and the primary cold plate 5 is connected with a primary pulse tube 6, and the top of the cold head body 1 is provided with a primary gas tube connected with the primary pulse tube 6. Storehouse joint 7; the cold head body 1 is provided with a coiled pipeline 8 and an expansion chamber 9, the two ends of the coile...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com