A kind of wet-process zirconium-doped concentration gradient nickel-cobalt-aluminum ternary precursor and its preparation method

A concentration gradient and precursor technology, applied in chemical instruments and methods, nickel compounds, inorganic chemistry, etc., can solve problems such as difficult to achieve homogenization, and achieve the effects of good processing performance, stable performance, and high capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

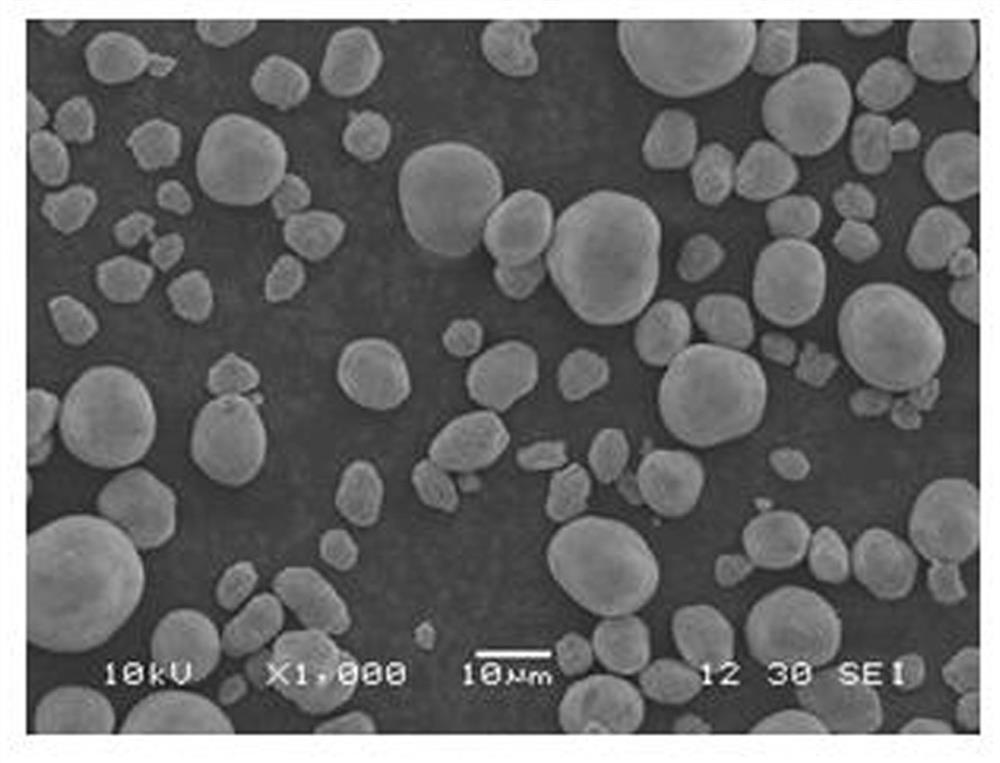

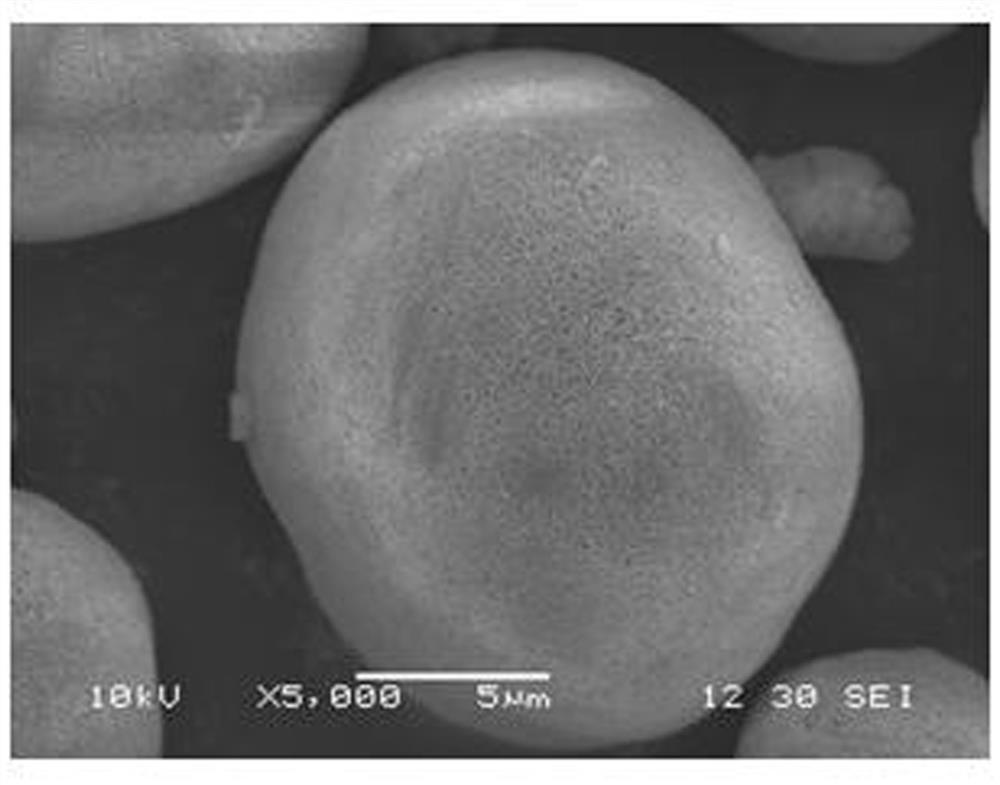

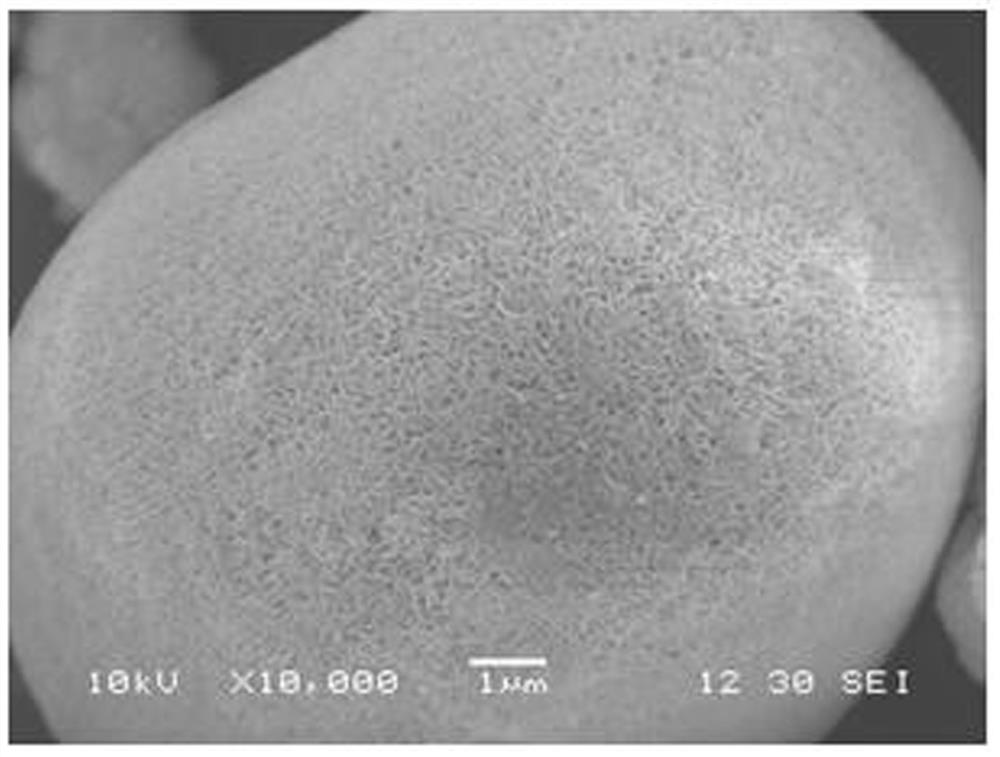

[0029] The embodiment of the preparation method of the nickel-cobalt-aluminum ternary precursor with a concentration gradient doped with zirconium in the present invention comprises the following steps:

[0030]Step 1: Prepare a nickel-cobalt soluble salt solution with a total concentration of 2.0mol / L according to the molar ratio of Ni:Co 0.80:0.15. The zirconium salt is a 0.3% zirconium sulfate solution of the total mass of nickel-cobalt hydroxide. Mix the dissolved salt solution with the zirconium salt solution, prepare an aqueous sodium hydroxide solution with a concentration of 8 mol / L, prepare an aqueous ammonia solution with a concentration of 10 mol / L, and prepare a sodium metaaluminate solution with a concentration of 0.6 mol / L; sodium metaaluminate solution It is obtained by dissolving solid aluminum sulfate in excess sodium hydroxide solution.

[0031] Step 2: Add the mother liquor with ammonia concentration of 0.15mol / L and pH=11.78 into the 6500L reaction kettle e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com