Method for dilute acid pretreatment of plant straws by microwave-cyclic compression percolation

A plant straw and pretreatment technology, applied in food science, biofuel, sugar production, etc., to achieve the effect of improving conversion rate, reducing follow-up process, and reducing concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

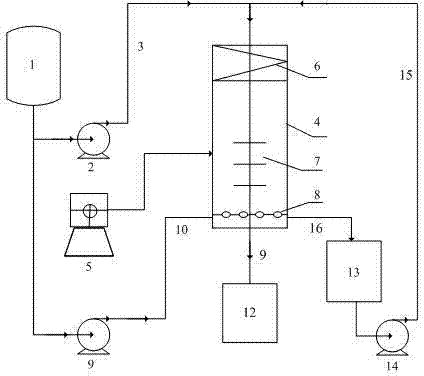

Method used

Image

Examples

Embodiment 1

[0035] (1) Crush the corn stalks into 10-20mm particles. Take 200g of straw particles and measure 400mL of prepared 0.5% (w / w) dilute sulfuric acid solution, which contains 0.1mol / L Fe 2 (SO 4 ) 3 , Slowly pour dilute sulfuric acid into a plastic bucket with corn stalks, stir repeatedly until the solid and liquid are evenly mixed, then seal it and let it soak at room temperature for 24 hours.

[0036] (2) Add the soaked corn stalks into the reactor, and feed 0.2% (w / w) dilute sulfuric acid at a rate of 80mL / min, which contains 0.08mol / L Fe 2 (SO 4 ) 3 , start the elastic compressor and the microwave generator at the same time, the microwave power is 1000w / (kg dry straw), the mode of action is to act on the microwave for 3min every 2min, the reaction temperature is controlled at 180°C, and the reaction pressure is 12atm.

[0037] (3) After the liquid in the reactor is separated from the solid, pump fresh acid into the reactor to submerge the solid. The concentration of the...

Embodiment 2

[0041] (1) Crush the corn stalks into 10-20mm particles. Take 200g of straw granules, measure 400mL of prepared 0.5% (w / w) dilute sulfuric acid, which contains 0.1mol / L Fe 2 (SO 4 ) 3 , Slowly pour dilute sulfuric acid into a plastic bucket with corn stalks, stir repeatedly until the solid and liquid are evenly mixed, then seal and soak at room temperature for 24 hours.

[0042] (2) Add the soaked corn stalks into the reactor, and feed 0.2% (w / w) dilute sulfuric acid at a rate of 120mL / min, which contains 0.08mol / L Fe 2 (SO 4 ) 3 , start the elastic compressor and the microwave generator at the same time, the microwave power is 2000 watts / (kg dry straw), the mode of action is to act on the microwave for 3 minutes every 2 minutes, the reaction temperature is controlled at 180 ° C, and the reaction pressure is 12 atm.

[0043] (3) After the liquid in the reactor is separated from the solid, pump fresh acid into the reactor to submerge the solid. The concentration of the fre...

Embodiment 3

[0047] (1) Take 200g of corn stalks with a particle size of 10-20mm, and measure 400mL of prepared 0.5% (w / w) dilute sulfuric acid, which contains 0.1mol / L Fe 2 (SO 4 ) 3 , Slowly pour dilute sulfuric acid into a plastic bucket with corn stalks, stir repeatedly until the solid and liquid are evenly mixed, then seal and soak at room temperature for 24 hours.

[0048] (2) Add the soaked corn stalks into the reactor, and feed 0.2% (w / w) dilute sulfuric acid solution at a rate of 160mL / min, which contains 0.08mol / L Fe 2 (SO 4 ) 3 , start the elastic compressor and the microwave generator at the same time, the microwave power is 3000 watts / (kg dry straw), the action mode is to act on the microwave for 3 minutes every 2 minutes, the reaction temperature is controlled at 180°C, and the reaction pressure is 12atm.

[0049] (3) After the liquid in the reactor is separated from the solid, pump fresh acid into the reactor to submerge the solid. The concentration of the fresh acid is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com