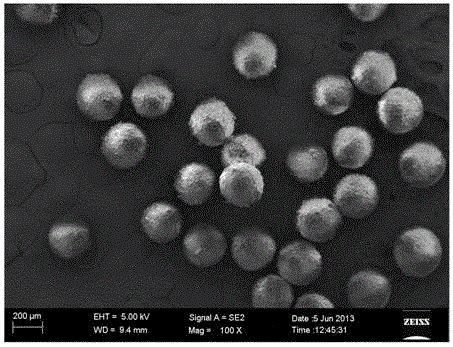

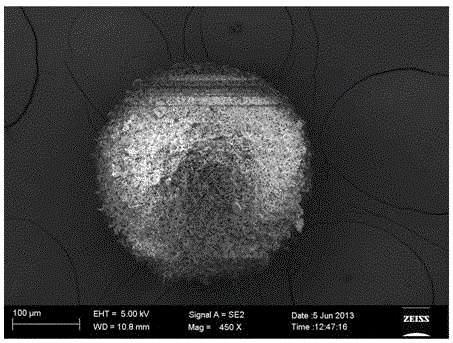

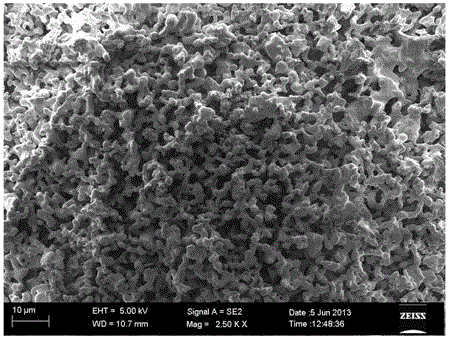

A device and method for preparing monodisperse spherical porous β-tcp particles

A monodisperse, particle technology, applied in the field of devices for preparing monodisperse spherical porous β-TCP particles, can solve the problems of lack of bone tissue growth pores, uneven particle size, low surface sphericity, etc., to achieve pore connectivity Beneficial, high surface sphericity, high fluidity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The suspension prepared by β-TCP powder, deionized water and ammonium polyacrylate is transferred to crucible 3 (such as figure 1 Shown), the size of the hole 6 on the baffle plate 7 is selected according to the size of the required β-TCP particles, and the amount of the suspension reaches 3 / 4~4 / 5 of the crucible molten pool 4.

[0046] Adjust the parameters of the pulse signal, choose the trapezoidal wave as the waveform (such as figure 2 shown), parameter values: rising edge 100~250μs, holding edge 700~1000μs, falling edge 1000~1200μs, frequency setting 1~10Hz, differential pressure control between 1~10Torr.

[0047] Utilize the differential pressure control system, pass the inert gas argon into the molten pool 4 through the upper vent pipe 11, so that a differential pressure of 1 kPa is generated with the vacuum chamber in the outer casing 5; apply an external pulse driving signal to the piezoelectric ceramic 1, Under its excitation, the piezoelectric ceramic 1 pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com