A preparation method of sulfonated waste polystyrene foam high-performance water reducer

A technology for discarding polystyrene and foamed plastics, applied in the field of preparation of high-performance water-reducing agents, can solve the problems of low production efficiency, large loss of concrete slump, difficult recycling of silver sulfate, etc., to save materials and The effect of production cost, saving production equipment investment, and shortening production preparation time

Active Publication Date: 2018-03-27

湖北凌安科技有限公司

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, SNF and SMF high-efficiency superplasticizers have been widely used and greatly developed in countries all over the world because of their small dosage and high water-reducing rate. The degree loss is relatively large, and the retarding component of the composite part in the high-efficiency superplasticizer is required

In the late 1980s, Japan developed a high-efficiency water reducer called aminosulfonic acid (AS). The raw material price of superplasticizer is relatively high, and it is sensitive to the dosage. If the dosage is too large, it is easy to bleed, which limits the large-scale use of AS high-efficiency superplasticizer in engineering.

[0006] But it is worth noting that there are still some problems and shortcomings in the process of preparing sulfonated waste EPS foam high-efficiency water reducer by traditional methods.

For example, the preparation of sulfonated waste EPS foam high-efficiency water reducer by solvent method requires a large amount of toxic organic solvents such as toluene, dichloroethane, cyclohexane, xylene, etc. These toxic organic solvents are volatile and will seriously pollute the air and atmospheric environment. At the same time, when using this method to prepare high-efficiency water reducers, the waste EPS foam needs to occupy a large amount of space in the reaction vessel, and the production efficiency is not high.

This preparation method also has the disadvantages of high reaction temperature and high requirements for production equipment.

However, the preparation of sulfonated waste EPS foam high-efficiency water reducer by the catalyst method requires the use of precious silver sulfate as a catalyst. Silver sulfate is difficult to recycle, which directly increases the production cost.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0034] A batch of sulfonated waste polystyrene foam (FOSEPS) high-performance water reducing agent is produced by adopting the preparation method described in the present invention for concrete application research.

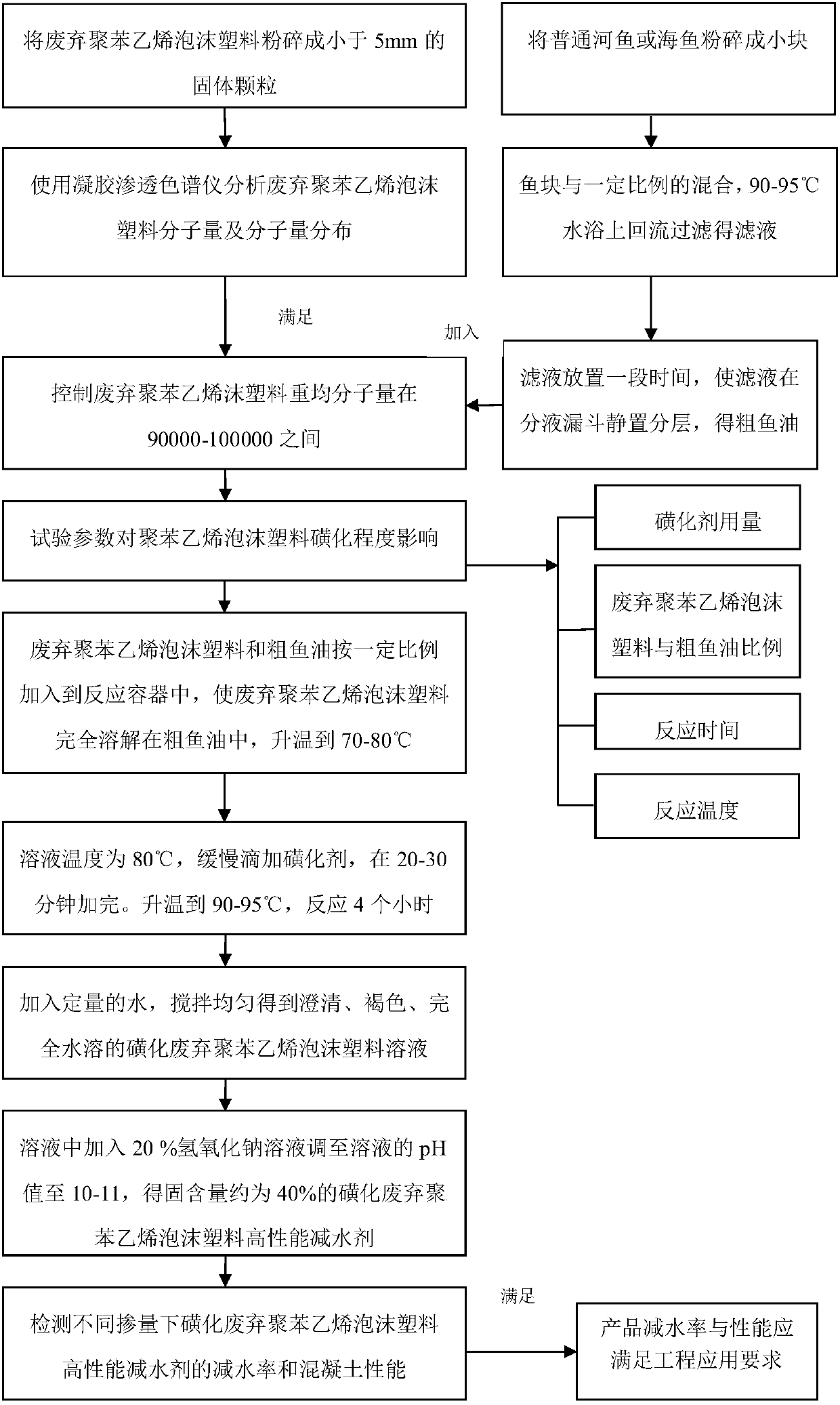

[0035] A preparation method of sulfonated waste EPS foam high-performance water reducer, the process is as follows figure 1 shown, including the following steps:

[0036] 1. Pretreatment of waste polystyrene foam

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Login to View More

Abstract

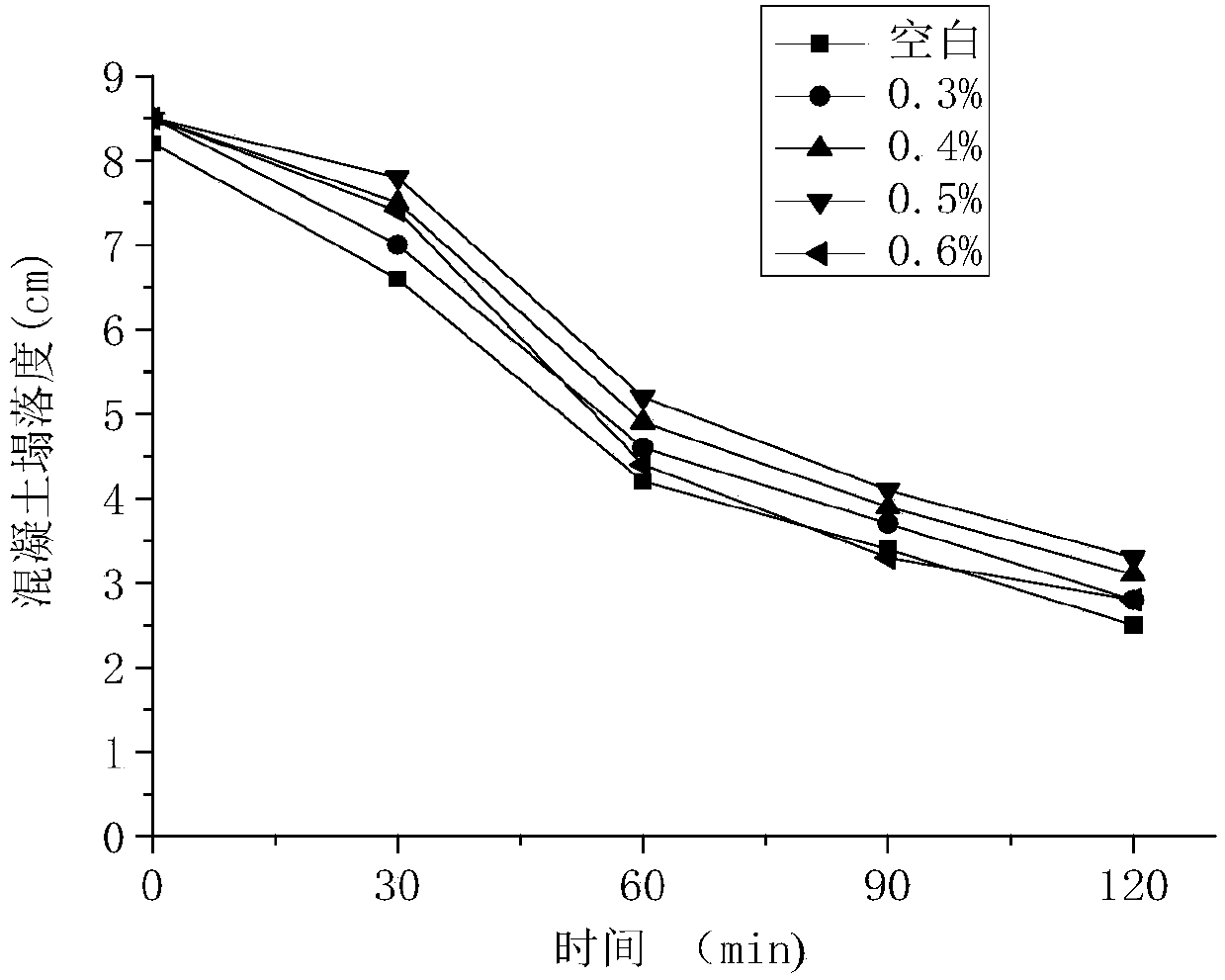

The invention discloses a preparation method of a sulfonated waste expanded polystyrene high-performance water reducing agent. According to the preparation method, natural biological fish oil is used as a solvent, so that the problem of environmental pollution caused when a large amount of toxic organic solvents need to be used in the traditional production process of sulfonated waste EPS high-efficiency water reducing agents is avoided, the clean production of the whole production process of the sulfonated waste EPS high-efficiency water reducing agents is realized, the production process of the sulfonated waste EPS high-efficiency water reducing agents is simplified, and the production efficiency is improved; and meanwhile, the fish oil contains effective components such as unsaturated fatty acid, so that defects of poor fluidity retentivity and short coagulation time of traditional concrete doped with the sulfonated waste EPS high-efficiency water reducing agents are further overcome, and the novel sulfonated waste expanded polystyrene high-performance water reducing agent has relatively high water reducing effect and fluidity retentivity.

Description

technical field [0001] The invention relates to a method for preparing a high-performance water reducer, in particular to a method for preparing a high-performance water reducer for sulfonated waste EPS foam plastics. Background technique [0002] In recent decades, the construction of marine structures such as cross-sea bridges, subsea tunnels, offshore drilling platforms, and marine wharves has been accelerating. High-performance concrete (HPC) has been more widely used as a construction material in marine engineering. The key to preparing HPC is the use of high-efficiency water-reducing agents. High-efficiency water-reducing agents can disperse cement particles and release free water in cement aggregates. Under the condition of maintaining the performance of concrete, the use of high-efficiency water-reducing agents can reduce Concrete water-cement ratio, improve the workability of fresh concrete and concrete slump loss, and make the concrete structure more compact. Hig...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C04B24/26C04B103/30

CPCC04B40/0039C04B2103/302C04B2201/50C04B24/2676C04B24/08C04B22/141C04B22/062

Inventor 赵晖邓敏杜杨徐海生韩颖

Owner 湖北凌安科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com