A kind of nano silver-lignin carbon composite material and its preparation method and application

A technology of lignin carbon and composite materials, which is applied in the preparation of organic compounds, preparation of amino hydroxyl compounds, chemical instruments and methods, etc., can solve the problem of difficulty in reusing nano-silver-lignin composite materials, the inability to use nano-silver, and the mechanical strength Poor problems, to achieve the effect of enhancing reducing ability, enhancing binding force, and improving water dispersion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

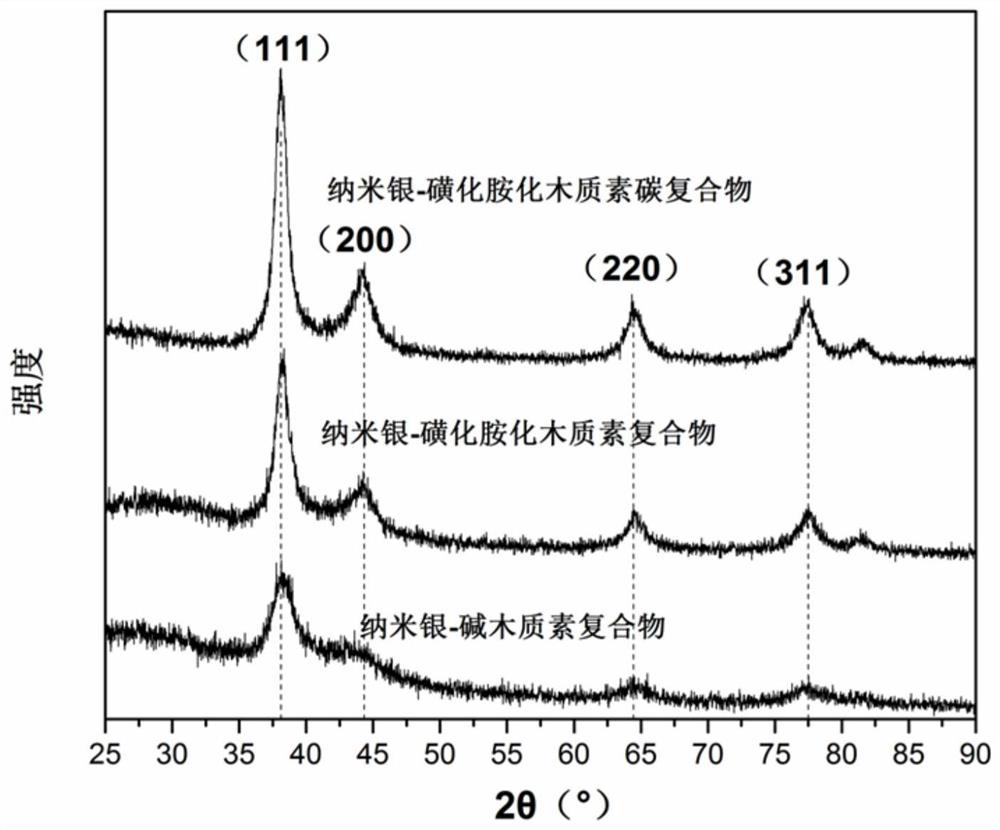

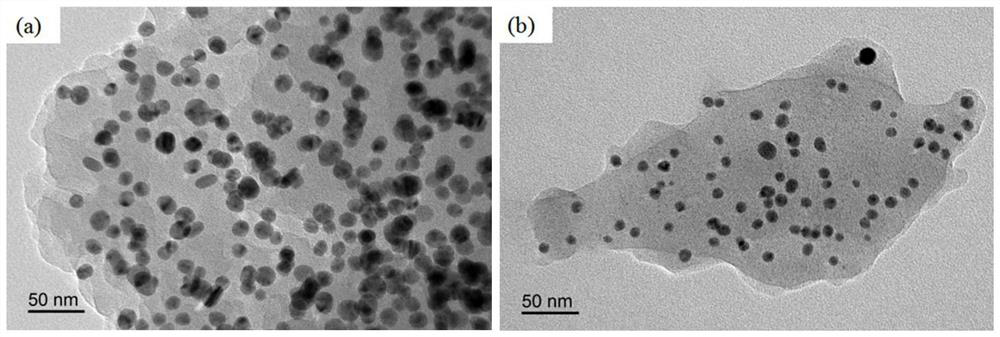

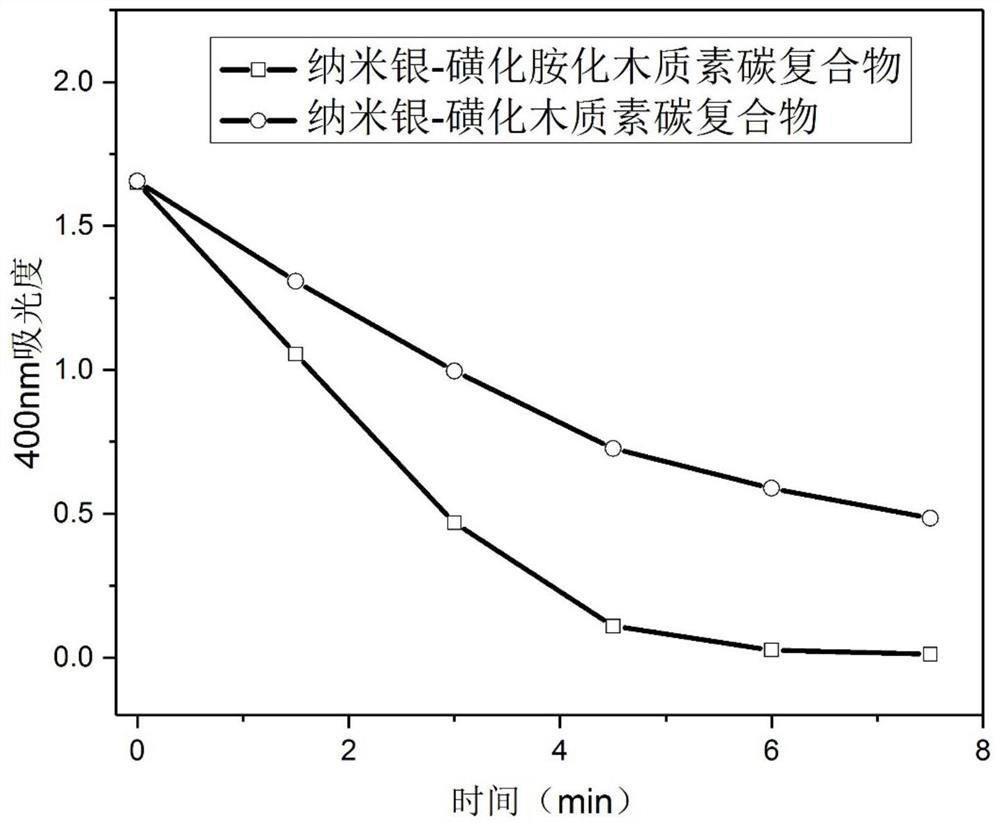

Embodiment 1

[0050] Add 100 parts by mass of wood pulp alkali lignin into water, add an aqueous solution of sodium hydroxide with a mass concentration of 20% under stirring to adjust the pH value to 11, and obtain an aqueous solution with a concentration of 30% by mass; add 10 parts by mass of sodium oleate at room temperature Stir for 1 hour, adjust the pH value to 5 with an aqueous nitric acid solution with a mass concentration of 10%, and precipitate lignin nanoparticles; add 5 parts by mass of sodium bisulfite and heat up to 140°C and stir for 2 hours; cool down to 70°C, in the above reaction solution Add 20% sodium hydroxide aqueous solution to adjust the pH to 9, add 100 mass parts of 37% formaldehyde solution and stir for 30 minutes, then add 100 mass parts of ethylenediamine and react for 2 hours; use 20% mass concentration of sodium hydroxide Aqueous solution Adjust the pH value of the above sulfonated aminated lignin solution to 9, add 35 parts by mass of silver nitrate, and react...

Embodiment 2

[0053] Add 100 parts by mass of bamboo pulp alkali lignin into water, add potassium hydroxide aqueous solution with a mass concentration of 20% under stirring to adjust the pH value to 10, and dissolve it into an aqueous solution with a concentration of 40% by mass percentage; add 5 parts by mass of twelve Alkyl sodium sulfate was stirred for 0.5h, and the pH value was adjusted to 6 with hydrochloric acid aqueous solution with a mass concentration of 10%, and lignin nanoparticles were precipitated; 20 parts by mass of magnesium bisulfite was added and the temperature was raised to 130°C and stirred for 3h; the temperature was lowered to 80°C , adding an aqueous solution of potassium hydroxide with a mass concentration of 20% to the above reaction solution to adjust the pH to 10, adding 50 parts by mass of 37% formaldehyde solution and stirring for 10 minutes, then adding 50 parts by mass of diethylenetriamine and reacting for 3 hours; using a mass concentration of 20% aqueous p...

Embodiment 3

[0056] Add 100 parts by mass of wheatgrass lignin to water, add a 20% aqueous sodium hydroxide solution under stirring to adjust the pH value to 9, and dissolve it into an aqueous solution with a concentration of 35% by mass; add 5 parts by mass of dodecane at room temperature Sodium phenyl sulfonate was stirred for 1 hour, and the pH value was adjusted to 4 with a sulfuric acid aqueous solution with a mass concentration of 10%, and lignin nanoparticles were precipitated; 10 parts by mass of ammonium bisulfite was added and the temperature was raised to 130°C and stirred for 4 hours; the temperature was lowered to 90°C , adding a mass concentration of 20% sodium hydroxide aqueous solution to the above reaction solution to adjust the pH to 9, adding 150 mass parts of 37% formaldehyde solution and stirring for 40 minutes, then adding 150 mass parts of triethylenetetramine and reacting for 4 hours; using a mass concentration of 20% aqueous sodium hydroxide solution adjusted the pH...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com