A method for preparing biochar from organic waste by sulfonated carbon low-temperature catalysis

A technology of organic waste and biochar, applied in chemical instruments and methods, physical/chemical process catalysts, biofuels, etc., to achieve strong adsorption capacity, large specific surface area, and high value-added resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

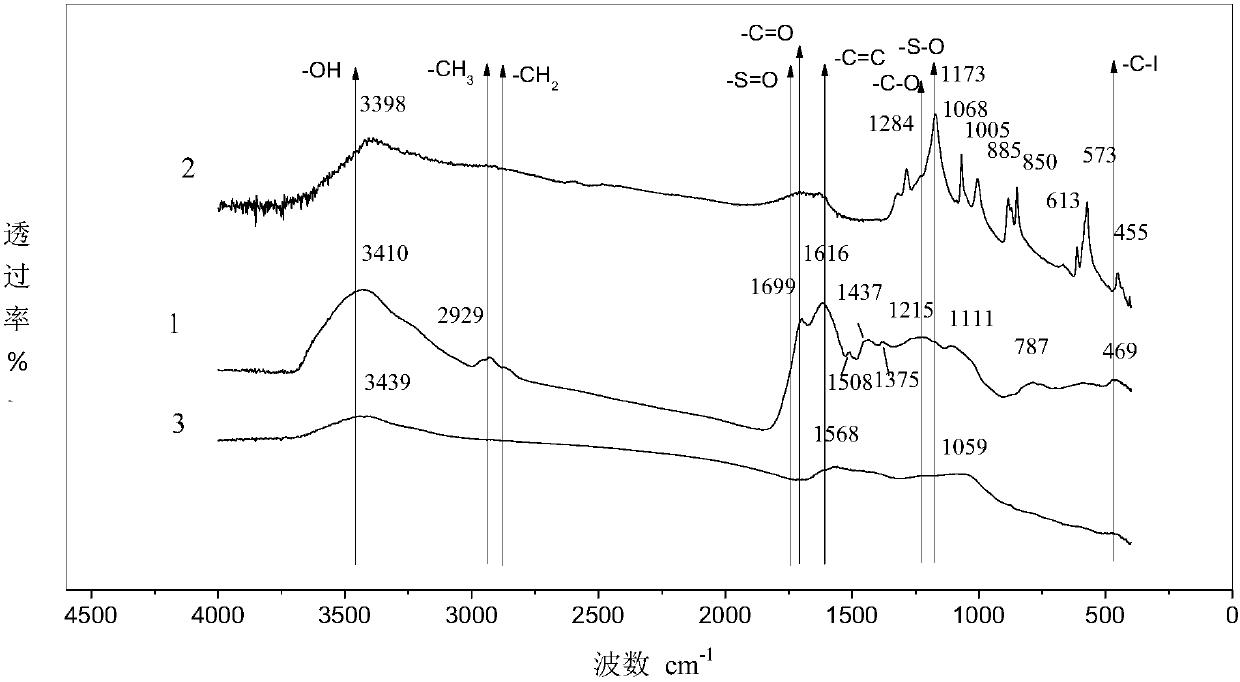

[0026] Crush corn stalks into small pieces of 1-3 cm, heat them in an oxygen-limited muffle furnace at 480°C for 2 hours, and cool naturally to room temperature to prepare aromatic ring biochar, and then put the biochar into PTFE-lined reaction In the kettle, completely submerged with 98% oleum, sulfonated at 105°C under oxygen-limited conditions for 12 hours, suction-filtered and rinsed the sulfonated sulfonated carbon to pH 4.5, and freeze-dried at -18°C for 18 hours. A sulfonated carbon catalyst was obtained. attached by figure 1 The SEM images and attached figure 2 It can be seen that the specific surface area, high porosity and high sulfonation rate of sulfonated carbon are 112.5m 2 / g, 0.028cm 3 / g, 2.4mmol / g.

[0027] Crush the agricultural waste corn stalks to less than 0.5 cm, mix the sulfonated carbon catalyst and the crushed corn stalks evenly at a mass ratio of 1:100, and evenly spray clean water accounting for 1% of the total weight of the mixture on the mixt...

Embodiment 2

[0030] Grinding the waste residue of traditional Chinese medicine to below 0.2 cm, mixing the sulfonated carbon catalyst prepared in Example 1 and the waste residue of Chinese medicine after crushing with a mass ratio of 1:98, and spraying evenly on the mixture to account for 0.5% of the total weight of the mixture After being stirred evenly, the purified water enters the rotary heating reactor, and is heated in a closed rotary heater with a furnace temperature of 130°C for 2 hours, and the reactor speed is 100 revolutions / h to obtain biochar. attached by Figure 4 The SEM image shows that the biochar has a large specific surface area, high porosity, and high carbonization ratio, which are 100.1m 2 / g, 0.019cm 3 / g, 99.5%. The biochar has a maximum adsorption capacity of 13.5 mg / g for polybrominated diphenyl ethers BDE-47 with a concentration of 25 μg / L in sewage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Degree of sulfonation | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com