Preparation method for xylan polysulfate

A technology of xylan and sulfate, applied in the field of preparation of xylan polysulfate, can solve the problems of no practical value, low sulfonation rate, environmental pollution, etc., achieve excellent sulfonation ability, low toxicity, avoid The effect of severe environmental pollution burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

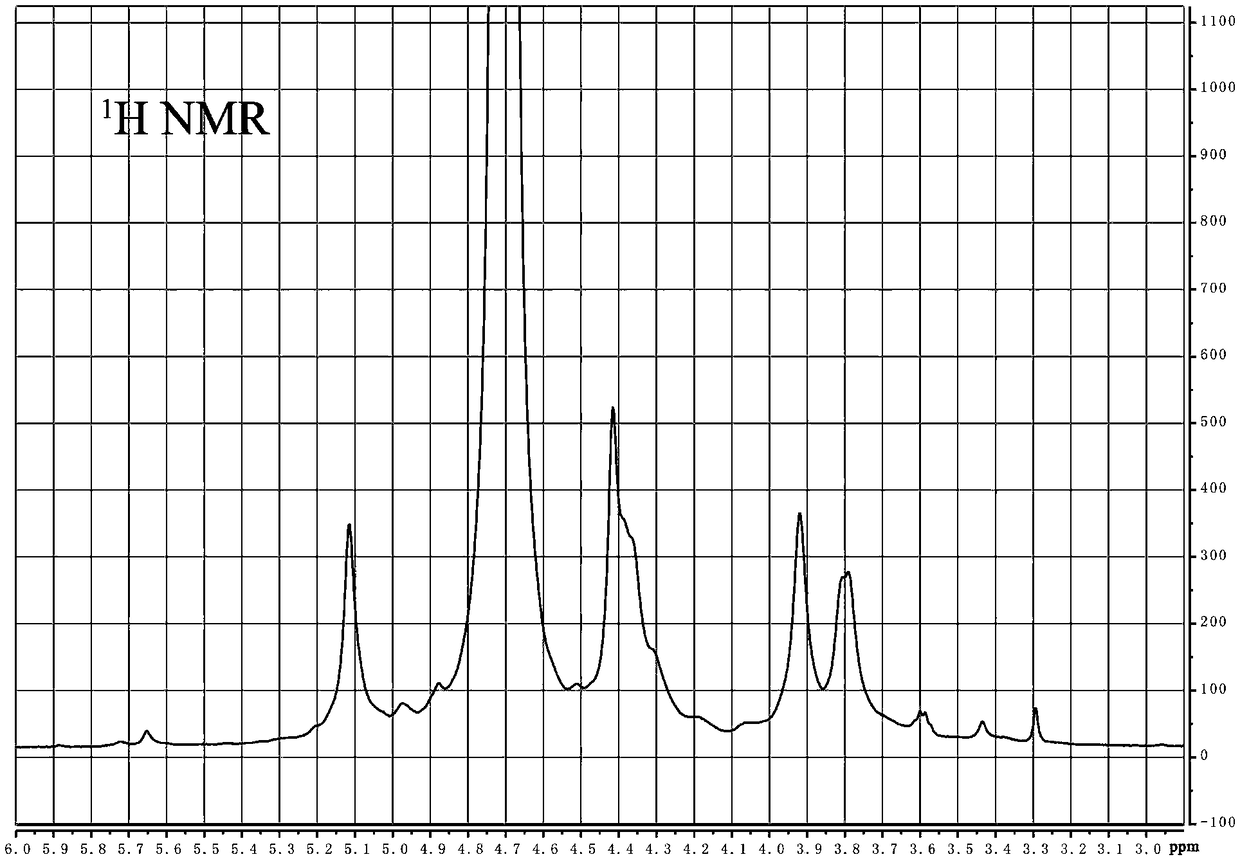

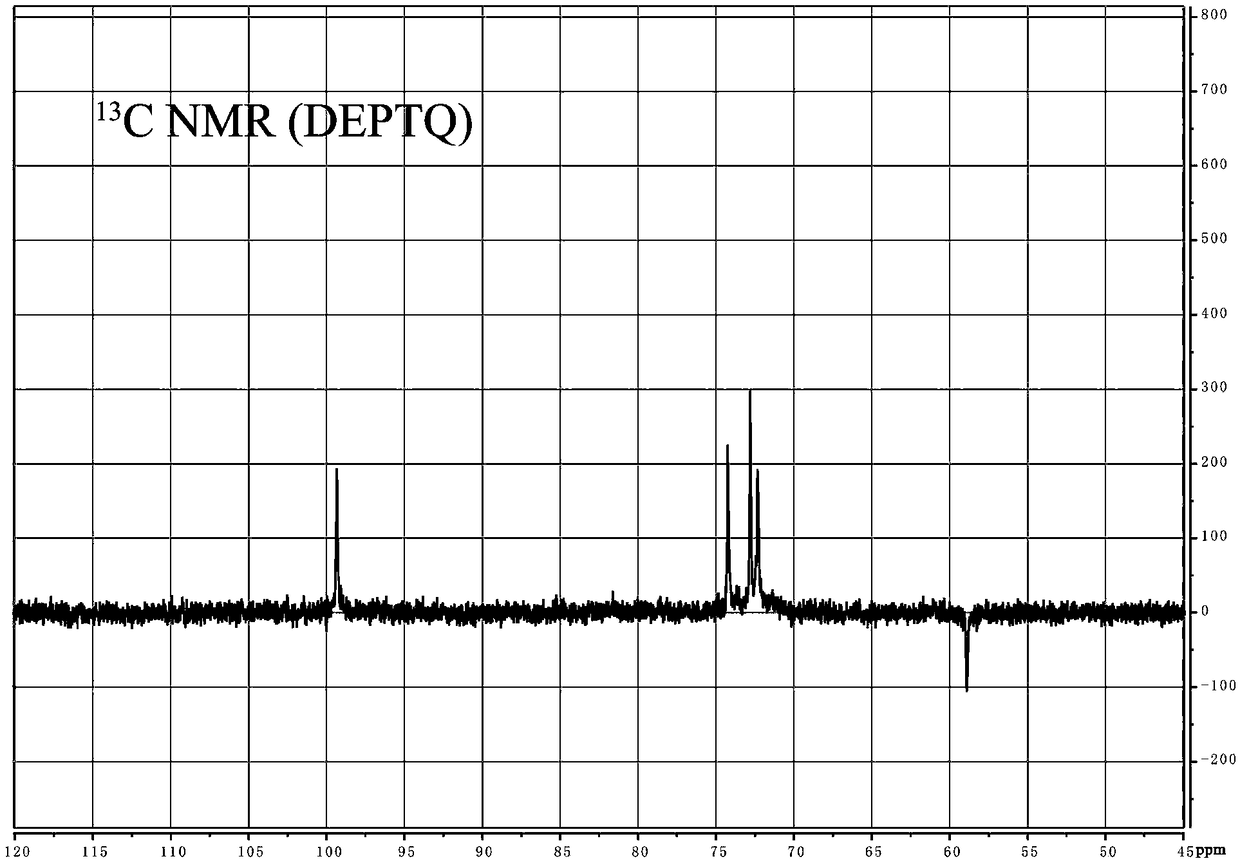

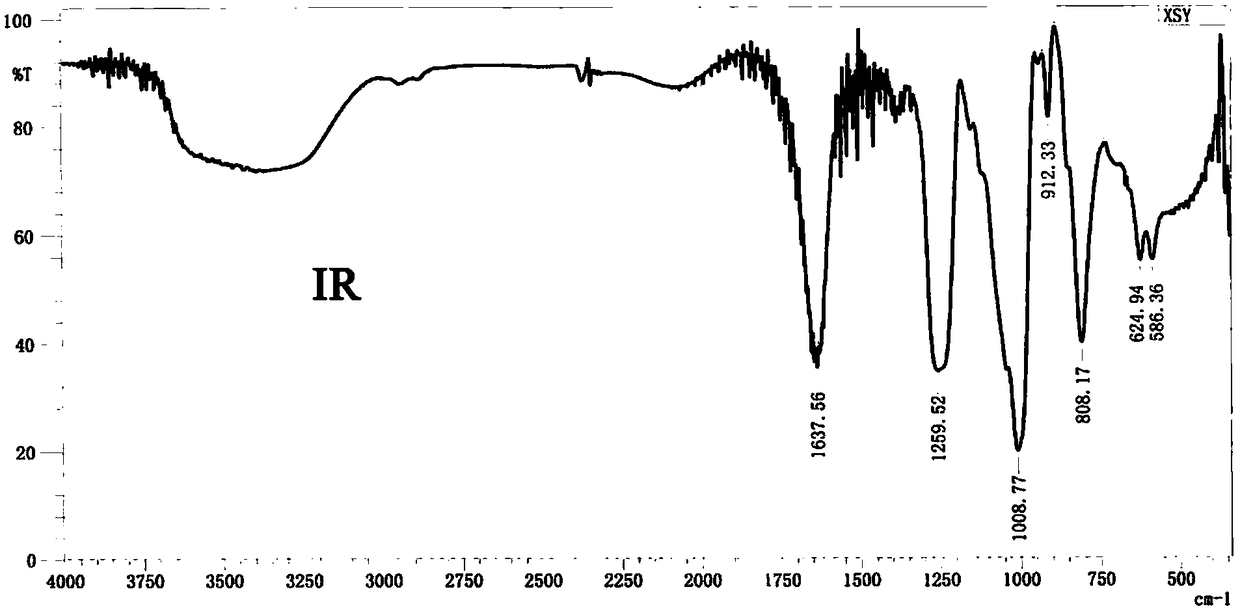

Image

Examples

Embodiment 1

[0036] The preparation method of the xylan polysulfate of the present embodiment, comprises the steps:

[0037] Step 1: Prepare the First Mixture

[0038] Weigh 60g xylan and 254g sulfur trioxide pyridine complex respectively, place them in a reaction kettle to obtain the first mixture;

[0039] Step 2: Prepare the Second Mixture

[0040] Add 750 mL of dimethyl sulfoxide to the first mixture obtained in step 1, react at 55° C. for 3 hours while stirring, and then lower it to room temperature of 20° C. to obtain the second mixture;

[0041] Step 3: Preparation of Crude Xylan Polysulfate

[0042] Dissolve 72g of NaOH in 100mL of water to obtain NaOH lye; add the above-mentioned lye to the second mixture obtained in step 2, stir well, then add 2L of methanol, filter the precipitate and dry to obtain 149g of xylan polysulfuric acid Crude salt;

[0043] Step 4: Preparation of xylan polysulfate finished product

[0044] Take 50 g of the crude xylan polysulfate obtained in step ...

Embodiment 2

[0049] The preparation method of the xylan polysulfate of the present embodiment, comprises the steps:

[0050] Step 1: Prepare the First Mixture

[0051] Weigh 100g of xylan and 411g of sulfur trioxide triethylamine complex respectively, and place them in a reaction kettle to obtain the first mixture;

[0052] Step 2: Prepare the Second Mixture

[0053] Add 2.5L of N,N-dimethylformamide to the first mixture obtained in step 1, react at 95°C for 1 hour while stirring, and then lower it to room temperature of 22°C to obtain the second mixture;

[0054] Step 3: Preparation of Crude Xylan Polysulfate

[0055] Dissolve 127g of KOH in 200mL of water to obtain KOH lye; add the above-mentioned KOH lye to the second mixture obtained in step 2, stir thoroughly, then add 5L of ethanol, filter the precipitate and dry to obtain 284g of xylan polysaccharide crude sulfate;

[0056] Step 4: Preparation of xylan polysulfate finished product

[0057] Take 100g of the crude xylan polysulfate...

Embodiment 3

[0061] The preparation method of the xylan polysulfate of the present embodiment, comprises the steps:

[0062] Step 1: Prepare the First Mixture

[0063] Weigh 45g xylan and 142g sulfur trioxide trimethylamine compound respectively, place in the reaction kettle, obtain the first mixture;

[0064] Step 2: Prepare the Second Mixture

[0065] Add 750 mL of N,N-dimethylacetamide to the first mixture obtained in step 1, react at 75°C for 2 hours while stirring, and then lower it to room temperature of 23°C to obtain the second mixture;

[0066] Step 3: Preparation of Crude Xylan Polysulfate

[0067] 38g Ca(OH) 2 Dissolve in 250mL water to make a suspension to obtain Ca(OH) 2 lye; to the second mixture obtained in step 2, add the above Ca(OH) 2 After fully stirring the lye, add 2L of a mixture of methanol and ethanol in any proportion, filter the precipitate and dry it to obtain 127g of xylan polysulfate crude product;

[0068] Step 4: Preparation of xylan polysulfate finishe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com