System device for preparing sulphonate surfactant through supergravity sulfonating method and application

A surfactant and system device technology, applied in the direction of sulfonic acid preparation, sulfonate preparation, chemical instruments and methods, etc., can solve the problems of heat transfer and mass transfer efficiency decline, complex reactor structure, and increased operating costs. Achieve the effects of avoiding local concentration unevenness, shortening residence time, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

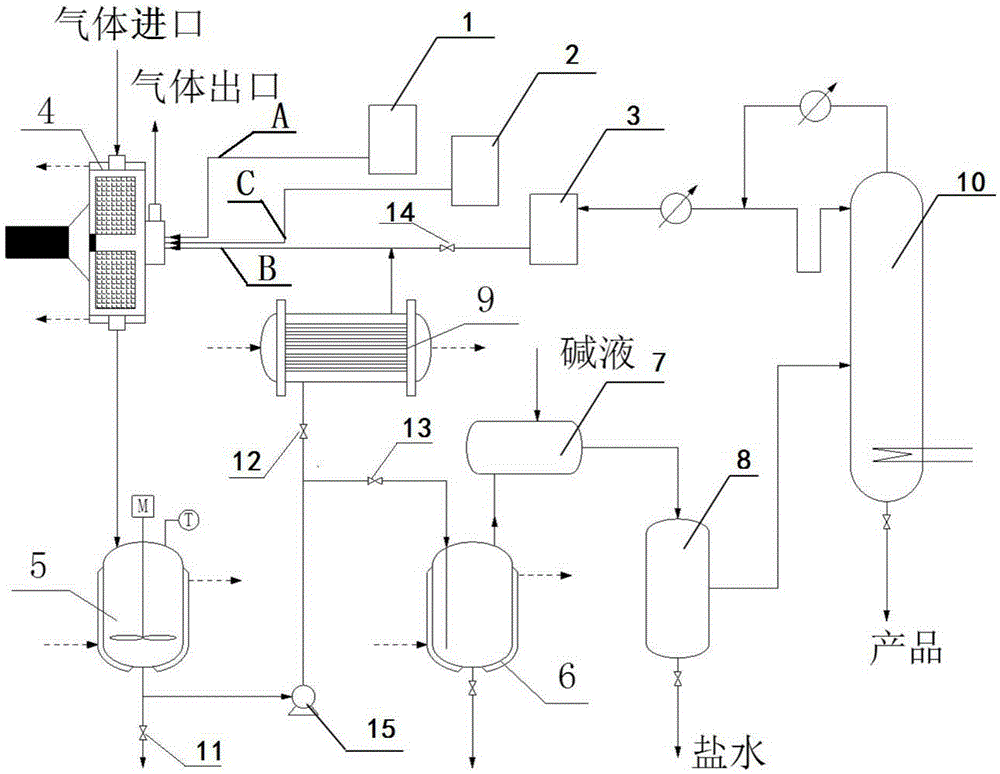

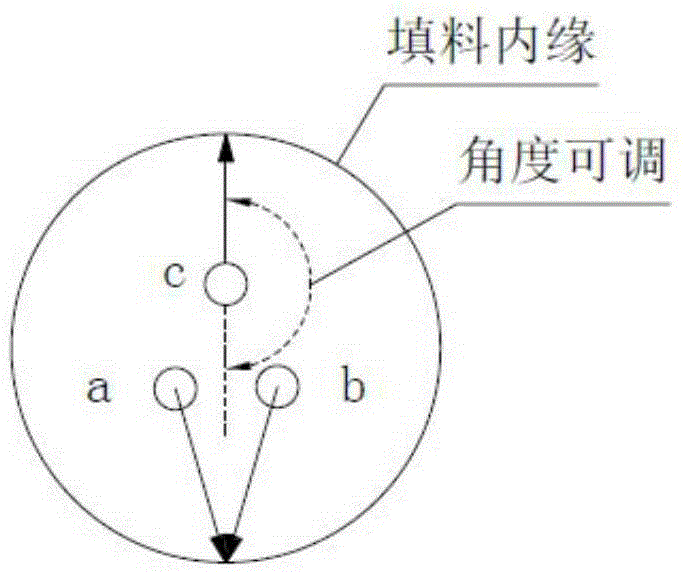

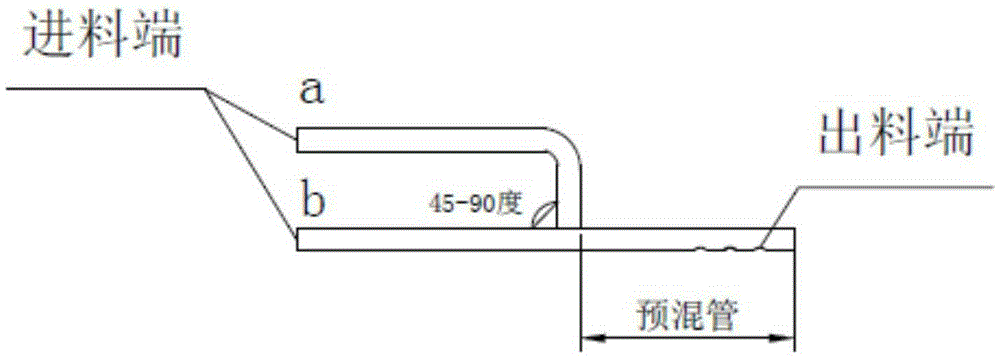

[0045] A system device for preparing sulfonate surfactants by supergravity sulfonation method, as attached figure 1 As shown, the system device includes a batching system, a hypergravity reaction system, a heat transfer system and a post-processing system; the batching system includes a sulfonating agent batching system 1, an organic solvent batching system 2 for heat transfer, and a batching System 3; the high-gravity reaction system includes a high-gravity reactor 4 and a feeding device; the heat transfer system includes an external heat transfer system 9 and a cold shock transfer system; the post-processing system includes a circulating stirring system 5, a circulating Pump 15, overflow aging system 6, neutralization system 7, water separation system 8 and solvent recovery system 10; the sulfonating agent batching system 1 is connected to the inlet pipeline A of the supergravity reactor 4; the raw material to be sulfonated The batching system 3 is connected to the inlet pip...

Embodiment 2

[0058]Use the system device of the present invention to carry out semi-continuous operation, add 1000 g of industrial linear dodecylbenzene raw materials with an average molecular weight of 246 at room temperature into the circulating stirring system 5 through the raw material batching system 3 to be sulfonated, and start the stirring paddle , circulation pump and supergravity reactor, adjust the rotor speed of the supergravity rotating packed bed reactor, and maintain the supergravity level as 100g. The material circulates between the circulating stirring system and the reactor, and the circulating water equipment is turned on at the same time. After the filler in the reactor is fully wet and the flow rate is stable, the sulfur trioxide gaseous sulfonating agent with a volume fraction of 7% is introduced into the reactor from the gas inlet. , Excluded through the air outlet. The molar mass ratio of dodecylbenzene to sulfur trioxide is 1:1.10. The reaction temperature was con...

Embodiment 3

[0060] The system device of the present invention is used for semi-continuous operation, and the industrial linear dodecylbenzene raw material with an average molecular weight of 1000 g at room temperature of 246 is added to the circulating stirring system 5 through the raw material batching system 3 to be sulfonated at one time, and the concentration is 5 The mixed gas of sulfur trioxide is passed into the supergravity reactor through the gas inlet, and the gas flow rate is 200L / h. Turn on the stirring paddle, the circulation pump and the supergravity reactor, adjust the rotor speed of the supergravity rotating packed bed reactor, and maintain the supergravity level as 150g. The material circulates between the circulating mixing tank and the reactor, and the circulating water equipment is turned on at the same time. After the filling in the reactor is fully wet and the flow is stable, the sulfonating agent is sprayed into the packing layer of the reactor through a peristaltic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com