High efficiency straw pulp sulfonated alkali lignin water-reducing agent and method for preparing same

A technology of sulfonated alkali lignin and high-efficiency water reducer, which is applied in the field of high-efficiency water reducer to achieve the effects of improving surface physical and chemical properties, saving cement, and having good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

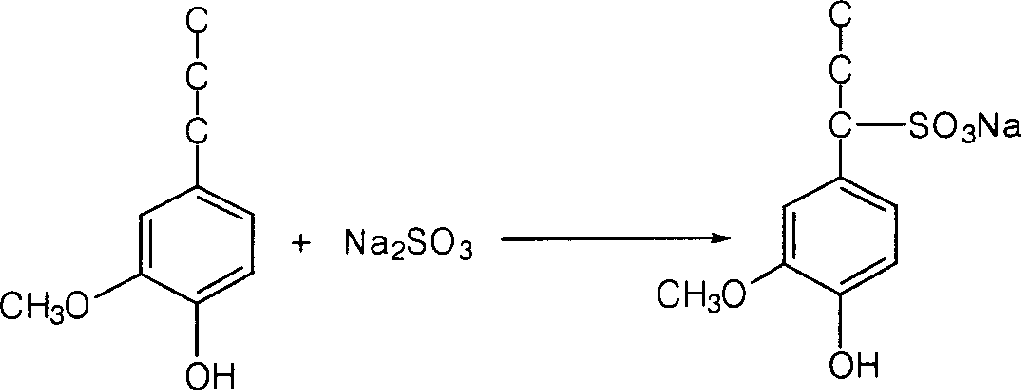

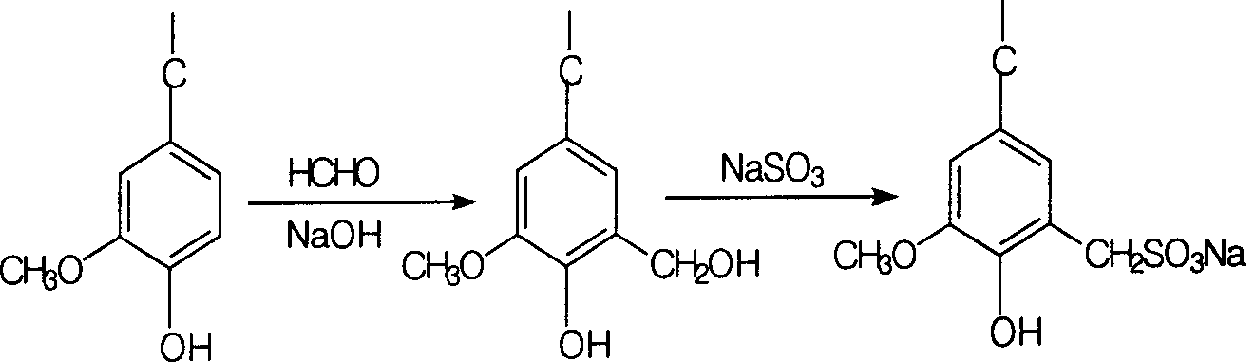

Method used

Image

Examples

Embodiment 1

[0031] First, take 500g of acid-analyzed grass pulp alkali lignin, add 1000g of water, 2mL of concentrated H 2 SO 4 , adjust the pH value to 5, and heat to 70°C while stirring; then add 0.8g FeCl 2 And 50g hydrogen peroxide, carry out catalytic oxidation reaction for 0.5 hours; finally add 50g formaldehyde, 200g sodium sulfite, carry out sulfomethylation reaction and condensation reaction for 4 hours. After cooling, the liquid product of high-efficiency water reducer can be obtained, and then the powder product can be obtained after drying.

Embodiment 2

[0033] First, take 500g of acid-analyzed straw alkali lignin, add 1000g of water and 10g of NaOH, adjust the pH value to 8, and heat to 60°C while stirring; then add 0.8g of FeCl 2 And 50g of hydrogen peroxide, carry out catalytic oxidation reaction for 1 hour; finally add 50g of formaldehyde, 50g of terephthalenedimethanol, 200g of sodium sulfite, carry out sulfomethylation reaction and condensation reaction for 3 hours. After cooling, the concrete high-efficiency water reducer liquid product can be obtained, and then the powder product can be obtained after drying.

Embodiment 3

[0035] First, take 500g of acid-analyzed straw alkali lignin, add 1000g of water and 20g of NaOH, adjust the pH value to 10, and heat to 80°C while stirring; then add 1g of FeCl 2 , 1gCu(NO 3 ) 2 And 75g of hydrogen peroxide, carry out catalytic oxidation reaction for 0.5 hours; finally add 25g of formaldehyde, 150g of terephthalenedimethanol, 100g of sodium sulfite, 50g of sodium bisulfite, carry out sulfomethylation reaction and condensation reaction for 2 hours. After cooling, the concrete high-efficiency water reducer liquid product can be obtained, and then the powder product can be obtained after drying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com