Crosslinked lignosulfonic acid based cation exchange resin as well as preparation method and application thereof

A lignosulfonic acid and cation exchange technology, which is applied in the field of cross-linked lignosulfonic acid-based cation exchange resin and its preparation, can solve the problem of high risk of sulfuric acid sulfonation reaction, low actual exchange equivalent of resin, and unsatisfactory exchange equivalent and other problems, to achieve the effect of simple and controllable synthesis process, high sulfonation efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

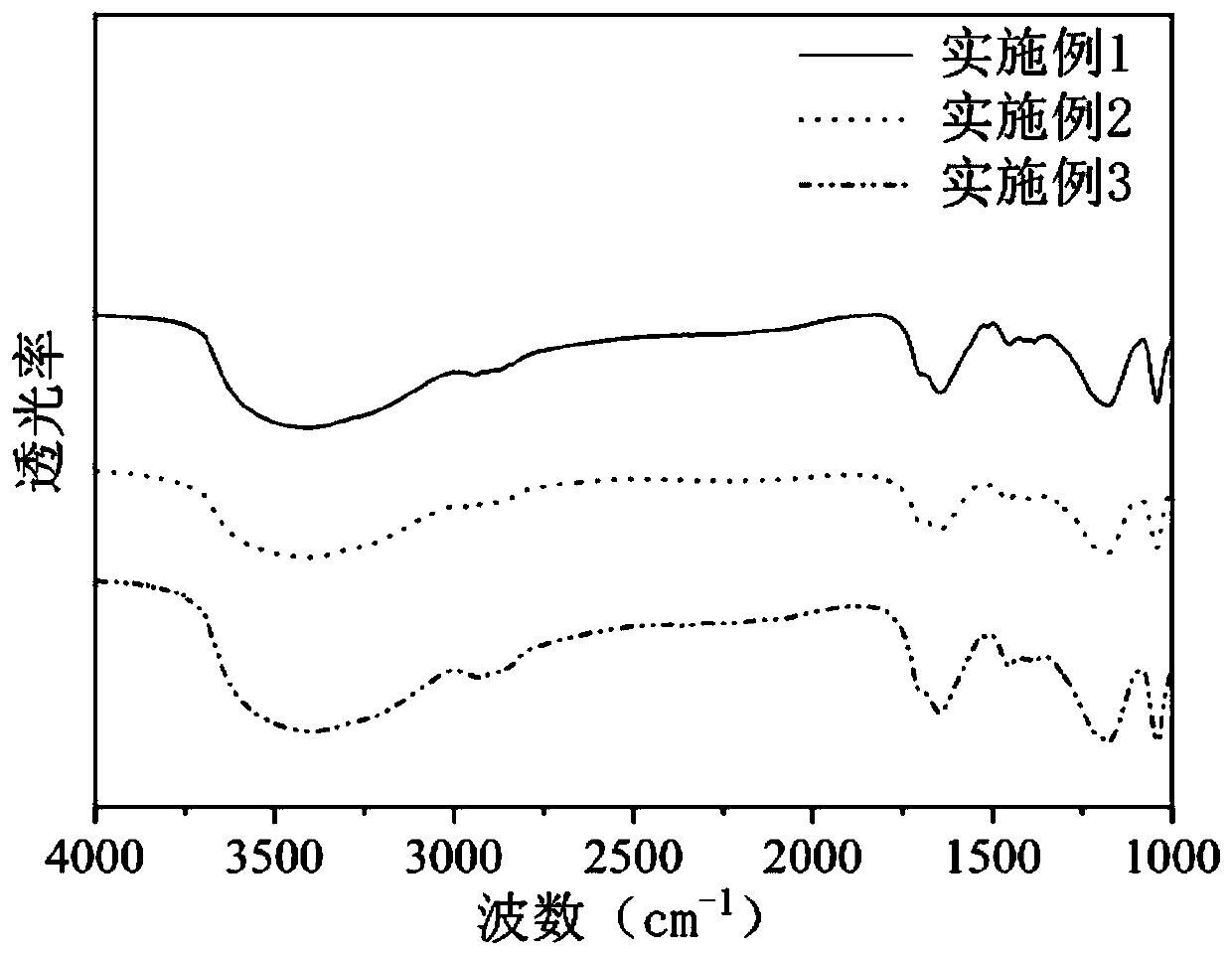

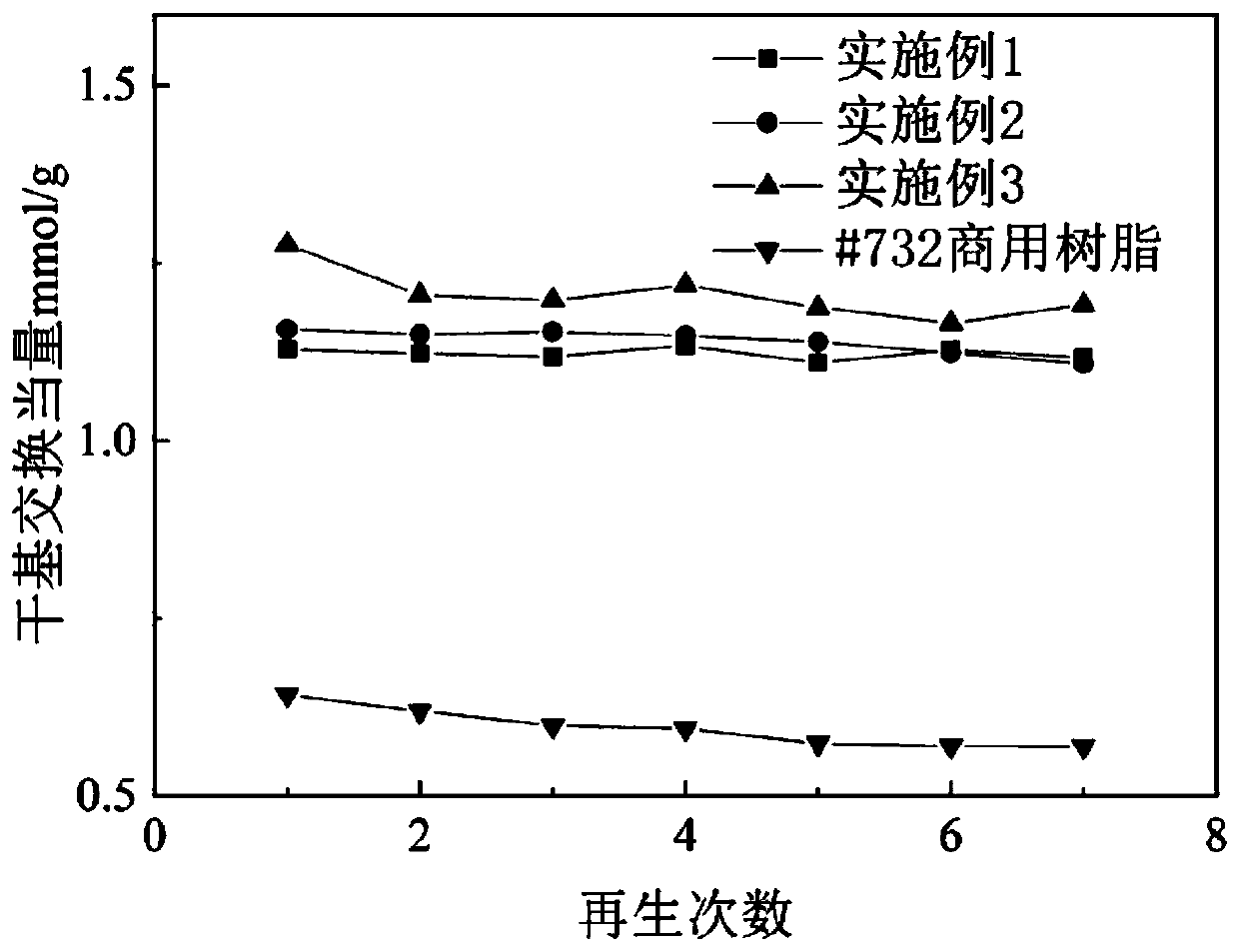

[0043] Dissolve 5 parts by mass of sodium sulfite, 8 parts by mass of sodium lignosulfonate and 6 parts by mass of acetone in 30 parts by mass of water, then raise the temperature to 40°C for 10 minutes, and then add 5 parts of formaldehyde dropwise within 0.5 hours; , heat up to 85°C for 1 hour and react for 1 hour to obtain a liquid active polycondensation product; put the liquid product in a closed container, add 2 parts by mass of epichlorohydrin and mix evenly, and then react at 90°C for 12 hours to obtain a cross-linked solid Resin, the product can be crushed to obtain 2mm cation exchange resin particles.

[0044] The sulfonic acid group content of the exchange resin product obtained in this embodiment is 2.501 mmol / g.

Embodiment 2

[0046] Dissolve 5 parts by mass of potassium sulfite, 10 parts by mass of ammonium lignosulfonate and 8 parts by mass of acetone in 40 parts by mass of water, then raise the temperature to 50°C for 15 minutes, and then add 12 parts by mass of formaldehyde dropwise within 0.5 hours; After the addition is completed, heat up to 90°C for 1 hour and react for 1 hour to obtain a liquid active polycondensate; put the liquid product in an airtight container, add 3 parts by mass of epichlorohydrin and mix evenly, then keep the temperature at 95°C for 24 hours to obtain a polycondensate Linked solid resin, the product can be crushed to obtain 3mm cation exchange resin particles.

[0047] The sulfonic acid group content of the exchange resin product obtained in this embodiment is 2.625 mmol / g.

Embodiment 3

[0049] Dissolve 5 parts by mass of sodium bisulfite, 15 parts by mass of potassium lignosulfonate and 10 parts by mass of acetone in 50 parts by mass of water, then raise the temperature to 60°C for 20 minutes, and add 10 parts by mass of formaldehyde dropwise within 0.5 hours; After the dropwise addition, the temperature was raised to 95°C for 1 hour of heat preservation reaction to obtain a liquid active polycondensation product; the liquid product was placed in an airtight container, and 4 parts by mass of epichlorohydrin was added to mix evenly, and then kept at 100°C for 24 hours to obtain Cross-linked solid resin, the product can be crushed to obtain 1mm cation exchange resin particles.

[0050] The sulfonic acid group content of the exchange resin product obtained in this embodiment is 2.891 mmol / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com