Zero-coal-consumption activated carbon production process and production device used in same

A technology for activated carbon production and coal consumption, applied in inorganic chemistry, non-metallic elements, carbon compounds, etc., can solve problems such as serious environmental pollution, affecting product quality, temperature instability, etc., achieve low energy consumption, realize recycling and reuse, zero The effect of coal consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

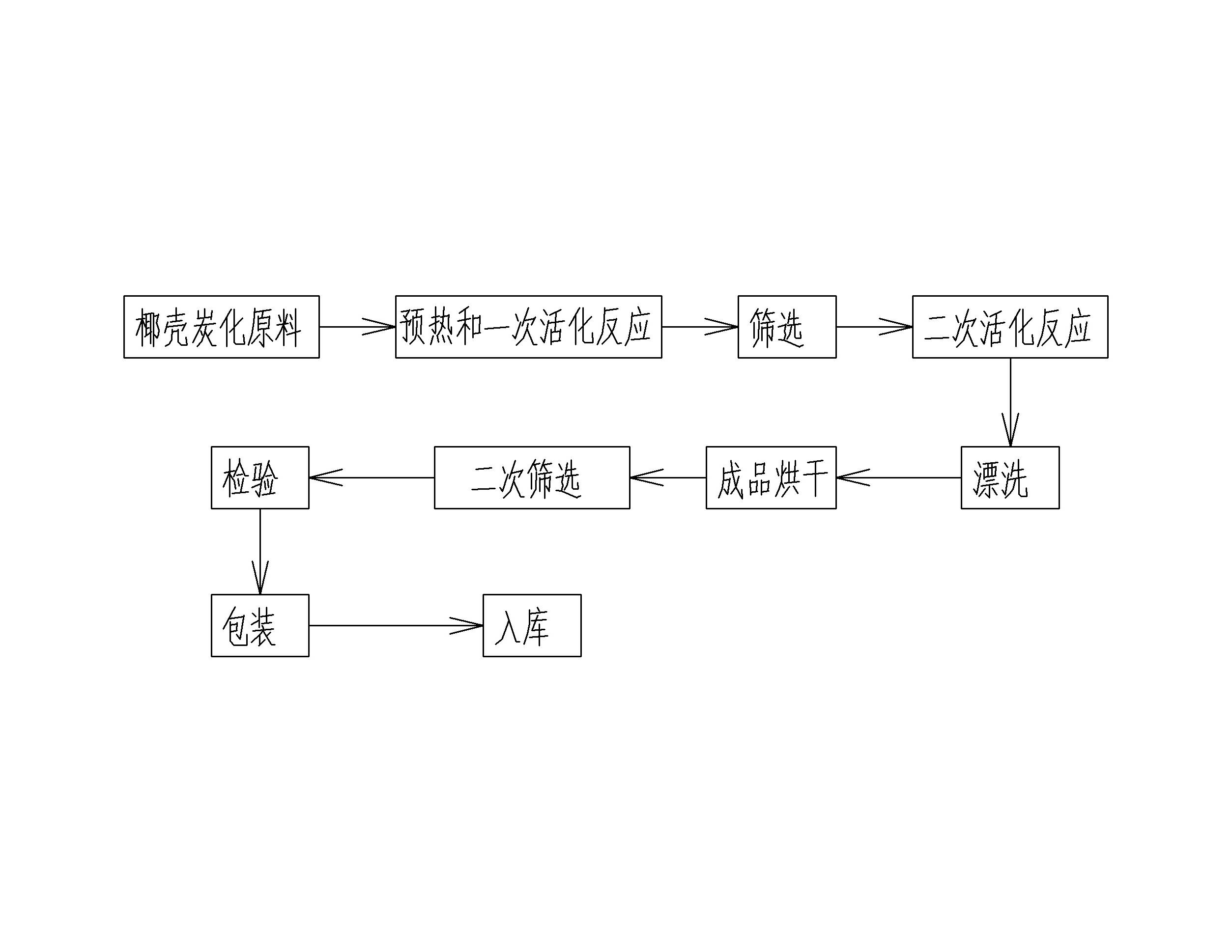

[0021] like figure 1 As shown, the present invention provides a kind of activated carbon production process of zero coal consumption, and it comprises the activation process, rinsing process and finished product drying process carried out successively, it is characterized in that: described activation process is divided into following several stages and carries out:

[0022] ① Preheating and primary activation reaction: Send the carbonized carbonized raw material (such as coconut shell carbonized material) into the primary activation furnace 1 (such as horizontal rotary furnace) to preheat the carbonized raw material and conduct a primary activation reaction; the flue gas generated by the primary activation reaction is sent to the primary activation waste heat steam boiler 2 through the first flue gas delivery pipe 8-1 for heating, so that the primary activation waste heat steam Boiler 2 produces steam and sends it to the primary activation furnace 1 through the first steam de...

specific Embodiment approach 2

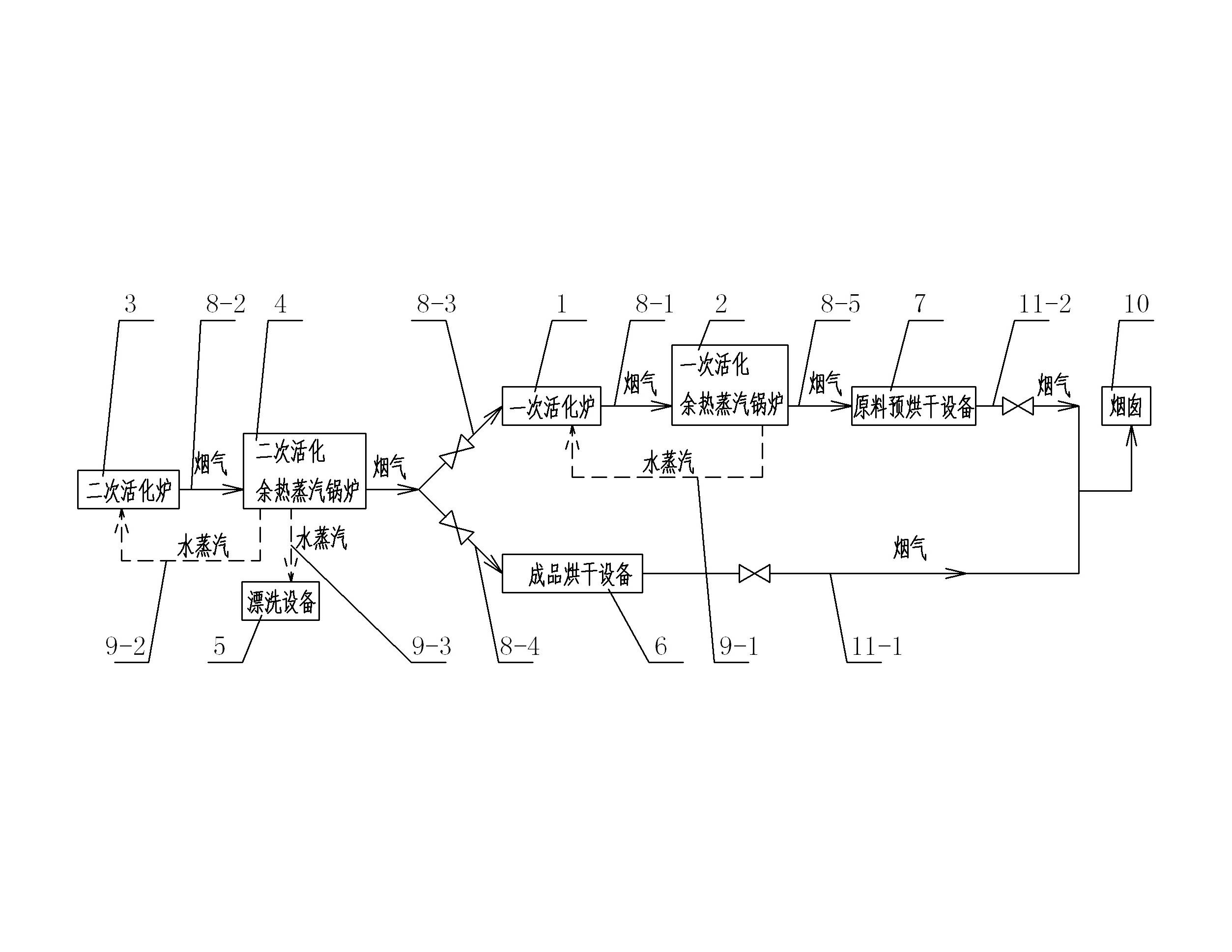

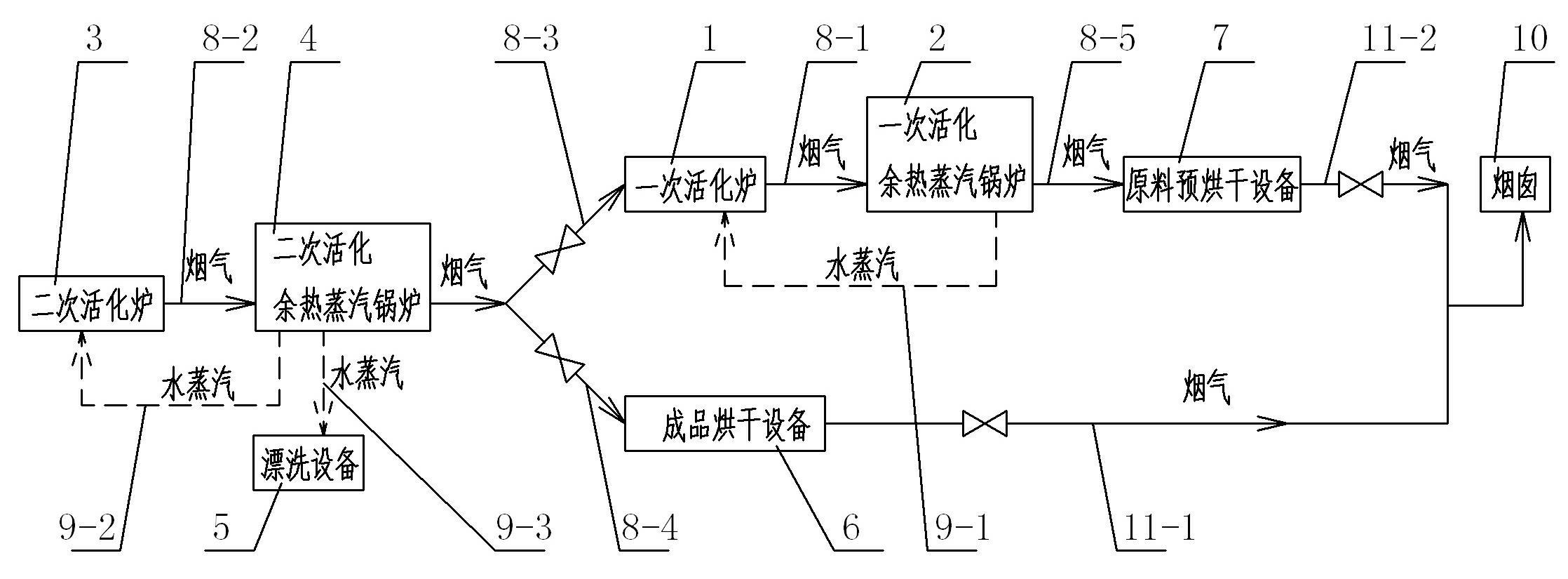

[0030] like figure 2As shown, the production device for the zero-coal-consumption activated carbon production process provided by the present invention, which includes activation equipment, rinsing equipment 5 and finished product drying equipment 6, is characterized in that: the activation equipment Including primary activation equipment and secondary activation equipment; said primary activation equipment includes primary activation furnace 1 and primary activation waste heat steam boiler 2, and a connection between primary activation furnace 1 and primary activation waste heat steam boiler 2 is used to discharge primary activation furnace 1 The flue gas is sent to the first flue gas delivery pipeline 8-1 of the primary activation waste heat steam boiler 2 and the first steam delivery pipeline 9-1 used to send the steam generated by the primary activation waste heat steam boiler 2 to the primary activation furnace 1 1; the secondary activation equipment includes a secondary...

Embodiment 1

[0037] Using coconut shell carbonized material as carbonized raw material, the zero coal consumption activated carbon production process is carried out in sequence according to the following steps:

[0038] ①Primary activation reaction: send the carbonized coconut shell carbonized material into the primary activation furnace 1 at a feed rate of about 0.2 tons / hour through an automatic feeder, and preheat the carbonized raw material and perform a primary activation reaction; The flue gas generated by the activation reaction is sent to the primary activation waste heat steam boiler 2 for heating through the first flue gas delivery pipe 8-1, so that the primary activation waste heat steam boiler 2 generates water vapor and sends it to the first steam delivery pipe 9-1. In the primary activation furnace 1, it is used as an activation catalyst for the primary activation reaction; the temperature of preheating and primary activation reaction is controlled around 800°C, the water vapo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com